Proper installation of measurement and pneumatic signal lines is essential for ensuring instrumentation accuracy, system safety, and long-term reliability. This document outlines key considerations and best practices during layout and installation.

1. Environmental and Routing Considerations

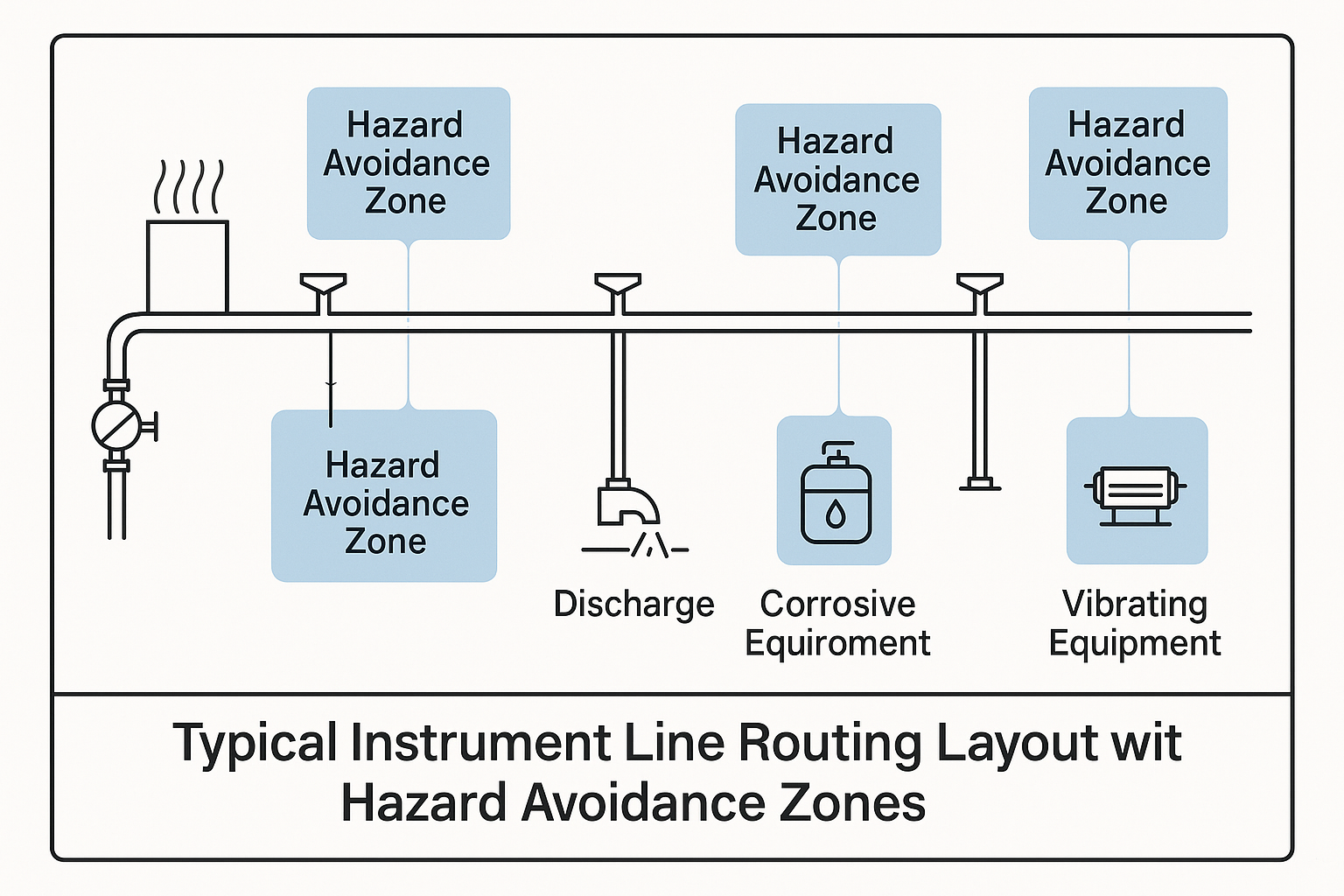

Avoidance of Hazards: Measurement and pneumatic signal lines should be routed away from high-temperature areas, corrosive environments, process venting points, mechanical vibration sources, and locations that obstruct maintenance activities.

Overhead Routing: Lines should be installed overhead whenever possible. Fixing should be secure and stable, minimizing unnecessary bends and crossovers.

Thermal Management: For media prone to freezing, condensing, solidifying, crystallizing, or vaporizing, apply heat tracing or thermal insulation to maintain line integrity.

🔧 Illustration 1: Typical Instrument Line Routing Layout with Hazard Avoidance Zones

2. Hydraulic and Pneumatic Performance Optimization

Static Head & Air Pockets: Layout should minimize additional static pressure heads, density variations, and trapped air or gas pockets within the measurement lines.

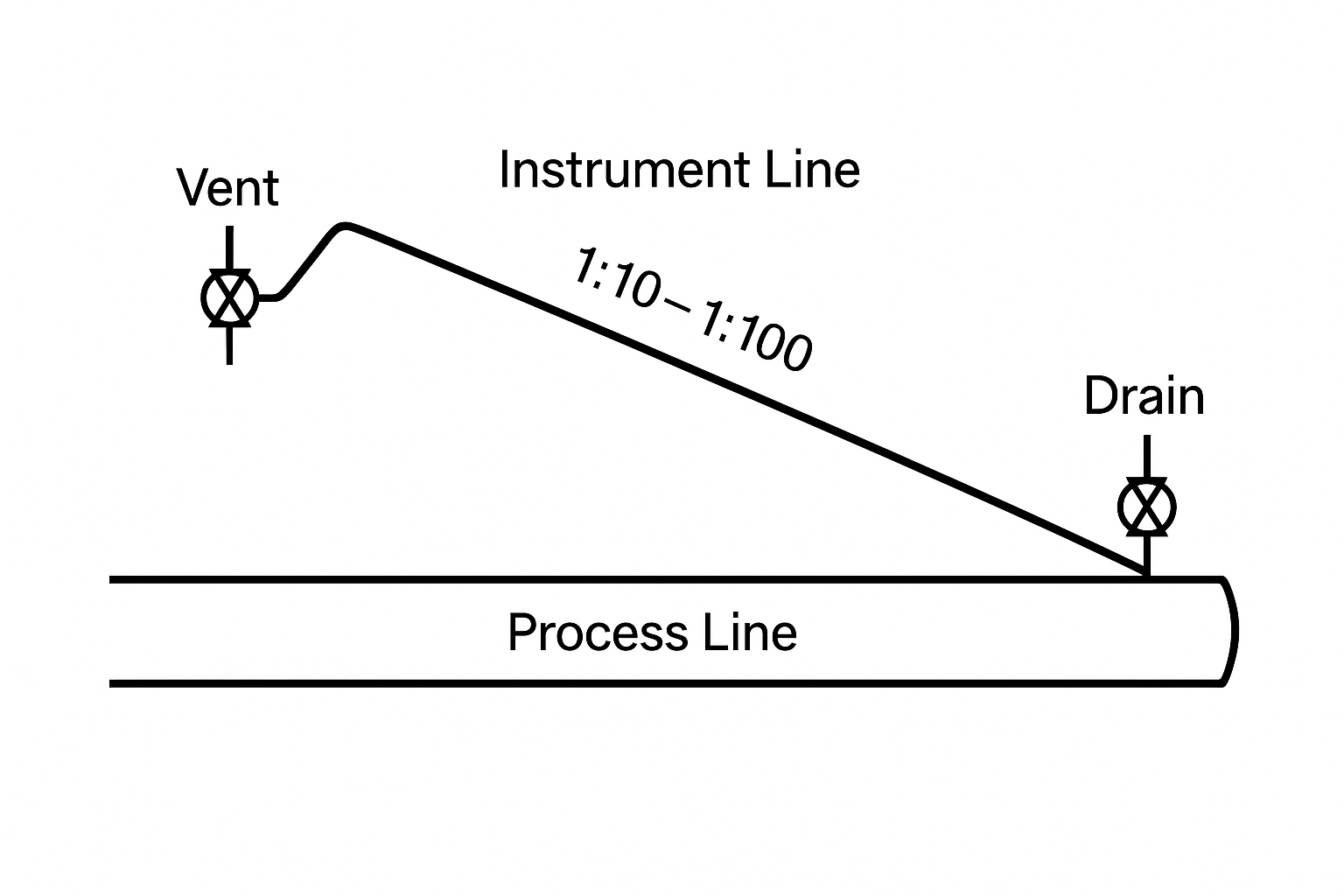

Slope Requirements: When installing horizontally, maintain a downward slope of 1:10 to 1:100 to facilitate fluid drainage or gas venting.

Drain/Vent Provisions:

For liquid-phase media, install air vents at the highest point if self-drainage is not possible.

For gas-phase media, install liquid drains at the lowest point.

For media containing sludge or sediment, provide drainage outlets at the lowest points.

🔧 Illustration 2: Sloped Line Arrangement with Drain and Vent Configurations

3. Safety and Emission Control

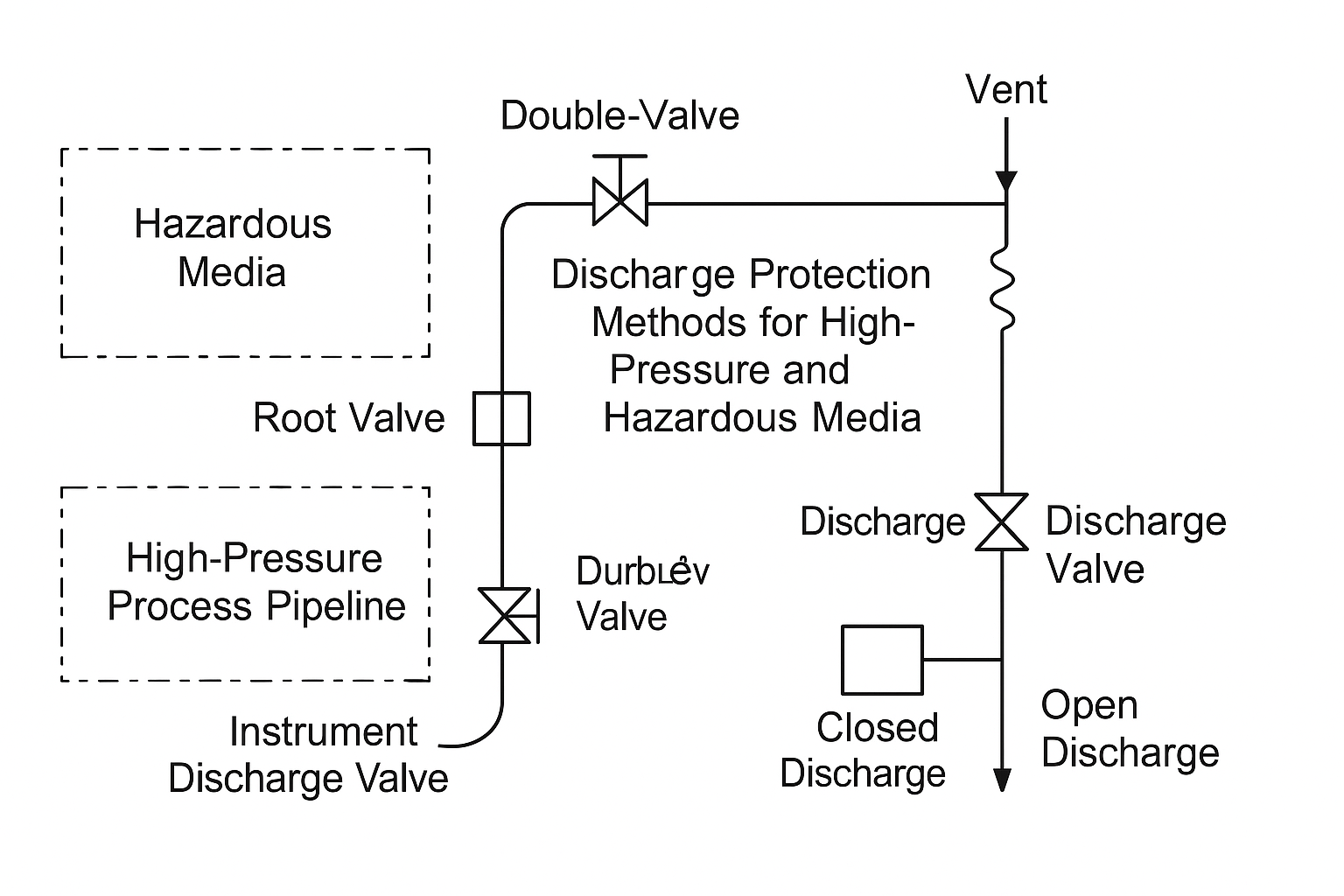

Toxic or Corrosive Media: Drainage and discharge should be directed to sealed disposal systems or designated safe collection points.

Pressure Containment:

For systems rated ≥ PN160 using dual root valves, instrument discharge valves must also be dual valve type or single valve with cap.

Atmospheric Interfaces: Any discharge port open to atmosphere must be fitted with plugs or protective covers, and stainless steel mesh guards should be used where appropriate.

🔧 Illustration 3: Discharge Protection Methods for High-Pressure and Hazardous Media

4. Compensation and Mechanical Support

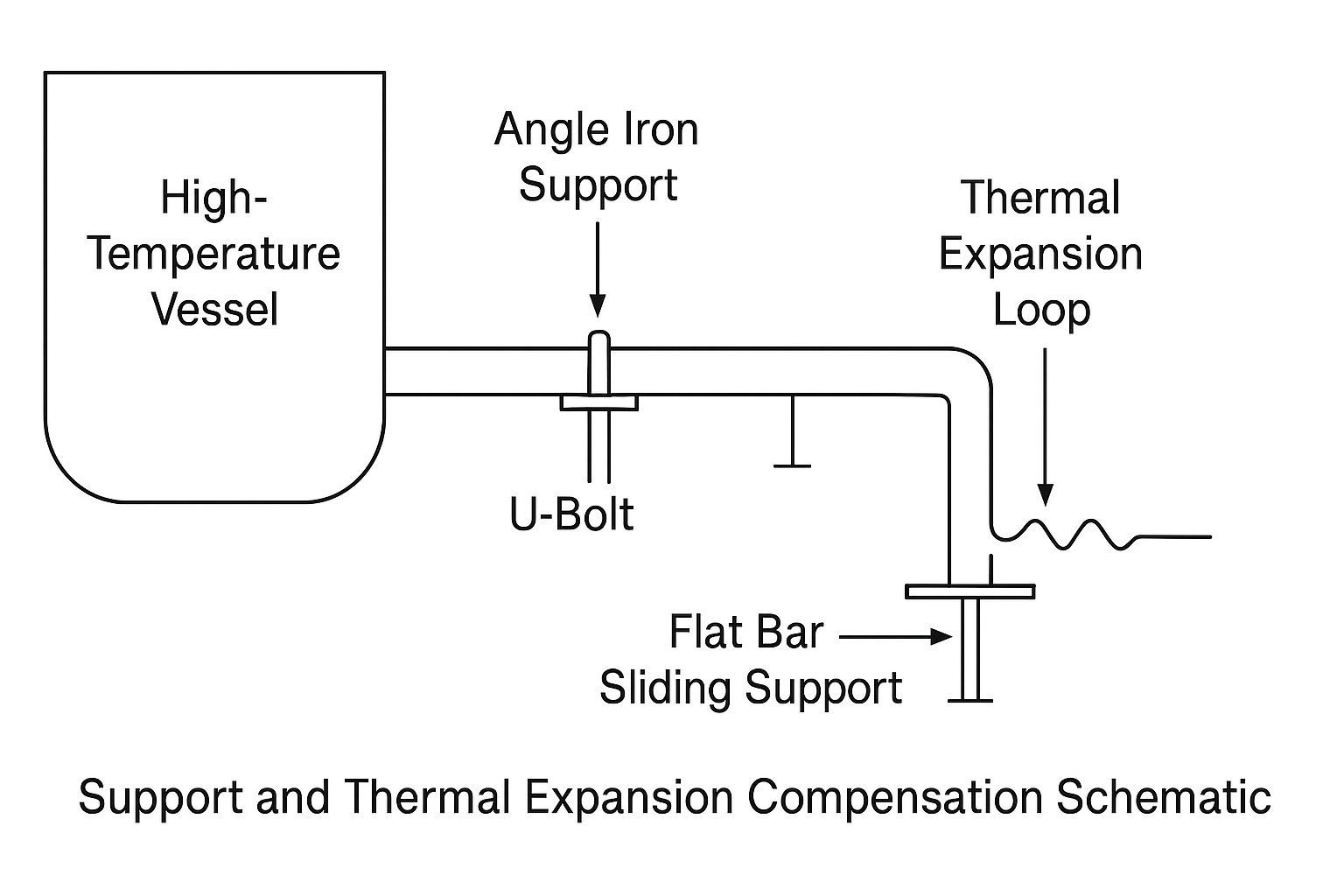

Thermal Expansion: When connected to high-temperature equipment or piping, implement thermal expansion compensation loops or flexible joints.

Support Structures: Use angle iron, flat bars, or U-bolts to secure pipes. Attach supports firmly to walls, frames, or pipe racks.

🔧 Illustration 4: Support and Thermal Expansion Compensation Schematic

5. Instrument Accuracy and Stability Requirements

Differential Pressure Lines: Both positive and negative pressure lines must be installed in areas with the same ambient temperature to prevent measurement drift.

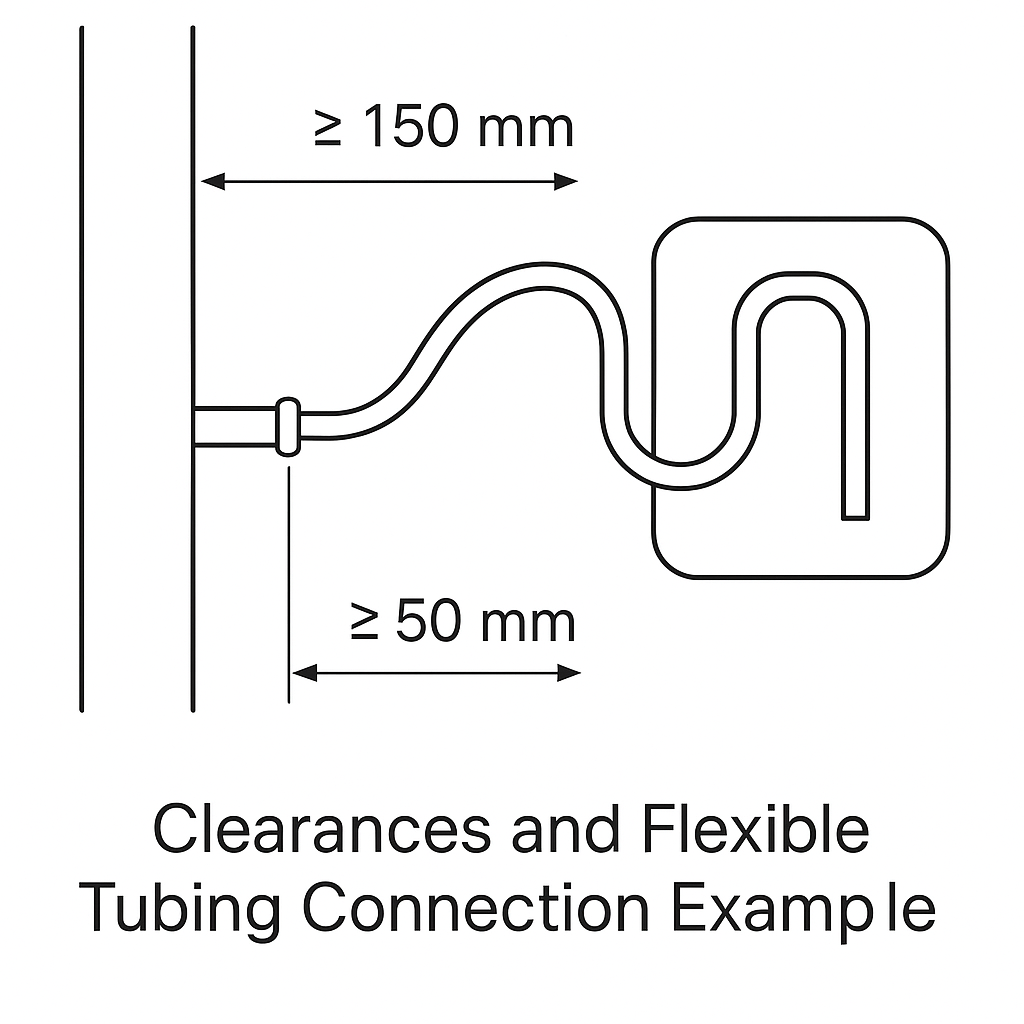

Flexible Connections:

When connecting to glass-type micromanometers, use flexible tubing.

The connection point should be 150–200 mm above the instrument inlet.

Clearance from Structures:

Maintain a minimum clearance of 50 mm between instrument tubing and adjacent surfaces.

For flammable or combustible liquids, the minimum distance from hot surfaces should be ≥ 150 mm, and tubing must not run parallel above such surfaces.

🔧 Illustration 5: Clearances and Flexible Tubing Connection Example

Summary Table: Key Installation Practices

| Category | Best Practice |

|---|---|

| Routing | Avoid heat, corrosion, obstruction, and vibration zones |

| Slope | 1:10 to 1:100 horizontal gradient |

| Drains & Vents | Add based on phase and position |

| Pressure Safety | Use dual valves or caps for high-pressure applications |

| Fixing & Support | Use angle iron, U-bolts, wall/frame/pipe rack mounting |

| Thermal Management | Apply insulation or heat tracing for critical media |

| Structural Clearance | ≥ 50 mm (general), ≥ 150 mm (flammable fluids near heat) |

| Differential Pressure Arms | Install at equal ambient temperature zones |