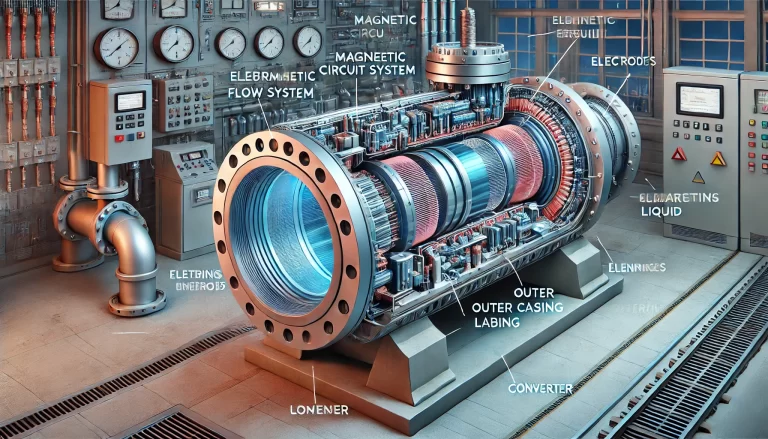

Electromagnetic flowmeters are precise instruments used in various industries for flow measurement. Proper installation is critical to ensure accuracy, reliability, and longevity of the device. This article outlines key installation considerations and provides detailed guidelines for achieving optimal performance.

1. Transportation and Handling

Guideline: For flowmeters smaller than DN100 (4 inches), avoid applying force to the signal transmitter during transportation.

Reason: The transmitter contains delicate components that can be damaged if mishandled.

Best Practice: Always handle the flowmeter by its main body and avoid exerting pressure on sensitive parts.

2. Installation Location

Guideline: Select a location where the motor shaft can remain horizontal regardless of positional changes.

Reason: A horizontal orientation minimizes stress and ensures accurate measurement.

Best Practice: Install the flowmeter on a stable section of the pipeline to avoid vibrations or external forces.

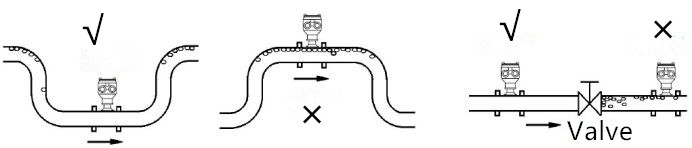

3. Pipe Filling

Guideline: Ensure that the flowmeter’s measurement pipe is always completely filled with the fluid.

Reason: Air pockets or incomplete filling can lead to inaccurate readings.

Best Practice: Choose an installation position where the pipe naturally remains full, such as a low point in the system or a vertical pipe with upward flow.

4. Flow Direction

Guideline: Align the flowmeter’s positive and negative flow directions with the medium’s actual flow.

Reason: Incorrect alignment can cause measurement errors or require additional calibration.

Best Practice: Use the directional arrow on the sensor body as a reference during installation.

5. Space for Bolts and Flanges

Guideline: Leave sufficient space between bolts, nuts, and pipe flanges for easy installation and removal.

Reason: Tight spaces may complicate maintenance or adjustments.

Best Practice: Ensure a clear working area around the installation site to facilitate future servicing.

6. Bypass Installation for Polluted Fluids

Guideline: For fluids prone to heavy contamination, install the flowmeter on a bypass pipeline.

Reason: This setup prevents clogging and facilitates maintenance without disrupting the main flow.

Best Practice: Include isolation valves in the bypass design for easy access and cleaning.

7. Large Flowmeters (DN > 200mm)

Guideline: Use adapter pipes when installing flowmeters larger than DN200 (8 inches).

Reason: Adapters help align flange axes and reduce installation difficulty.

Best Practice: Verify that the adapter pipe material and diameter match the pipeline specifications.

8. Straight Pipe Sections

Guideline: Maintain a minimum straight pipe section of 5DN (five times the pipe diameter) upstream and 2DN downstream.

Reason: Turbulence from upstream valves, bends, or pumps can affect measurement accuracy.

Best Practice: Install the flowmeter away from disturbances, ensuring a smooth flow profile.

9. Avoiding Electromagnetic Interference

Guideline: Do not install the flowmeter in areas with strong electromagnetic fields.

Reason: Electromagnetic interference from large electrical equipment or welding machines can disrupt sensor readings.

Best Practice: Place the flowmeter at least several meters away from potential interference sources and ensure proper grounding.

10. Environmental Temperature Requirements

Guideline: Follow these temperature guidelines:

If the product temperature is below 60°C, the ambient temperature should not exceed 60°C.

If the product temperature exceeds 60°C, the ambient temperature should not exceed 40°C.

Reason: High ambient temperatures can degrade performance or damage sensitive components.

Best Practice: Provide adequate ventilation or insulation to maintain the required operating conditions.

Additional Recommendations:

Regular Inspections: Periodically check for loose connections, debris, or scaling that might affect accuracy.

Documentation: Keep installation and maintenance records to track performance and identify recurring issues.

Training: Ensure personnel are trained to follow these guidelines to avoid mishandling or improper setup.

Conclusion

Following these detailed installation guidelines ensures that electromagnetic flowmeters operate efficiently and deliver accurate measurements. Proper installation not only improves performance but also extends the device’s service life, reducing downtime and maintenance costs in the long term.