Vortex flow meters, based on the Kármán vortex street principle, are widely used for measuring the flow of industrial fluids—gas, liquid, and steam. Proper installation and routine maintenance are crucial to ensuring their measurement accuracy and prolonging operational lifespan. This document outlines detailed guidelines for installation, daily inspection, and maintenance.

1. Installation Guidelines

1.1 Pre-Installation Preparation

Instrument Check: Verify the flow meter specifications (e.g., diameter, pressure rating, medium temperature, explosion-proof class) match the process requirements. Inspect the instrument for physical damage and ensure all accessories (flanges, bolts, gaskets, converter) are complete.

Pipeline Check: Ensure the pipeline is clean, free from rust or welding slag. Inner diameter should match the meter size to avoid eccentric or reduced-bore installation. Flush the pipeline if needed.

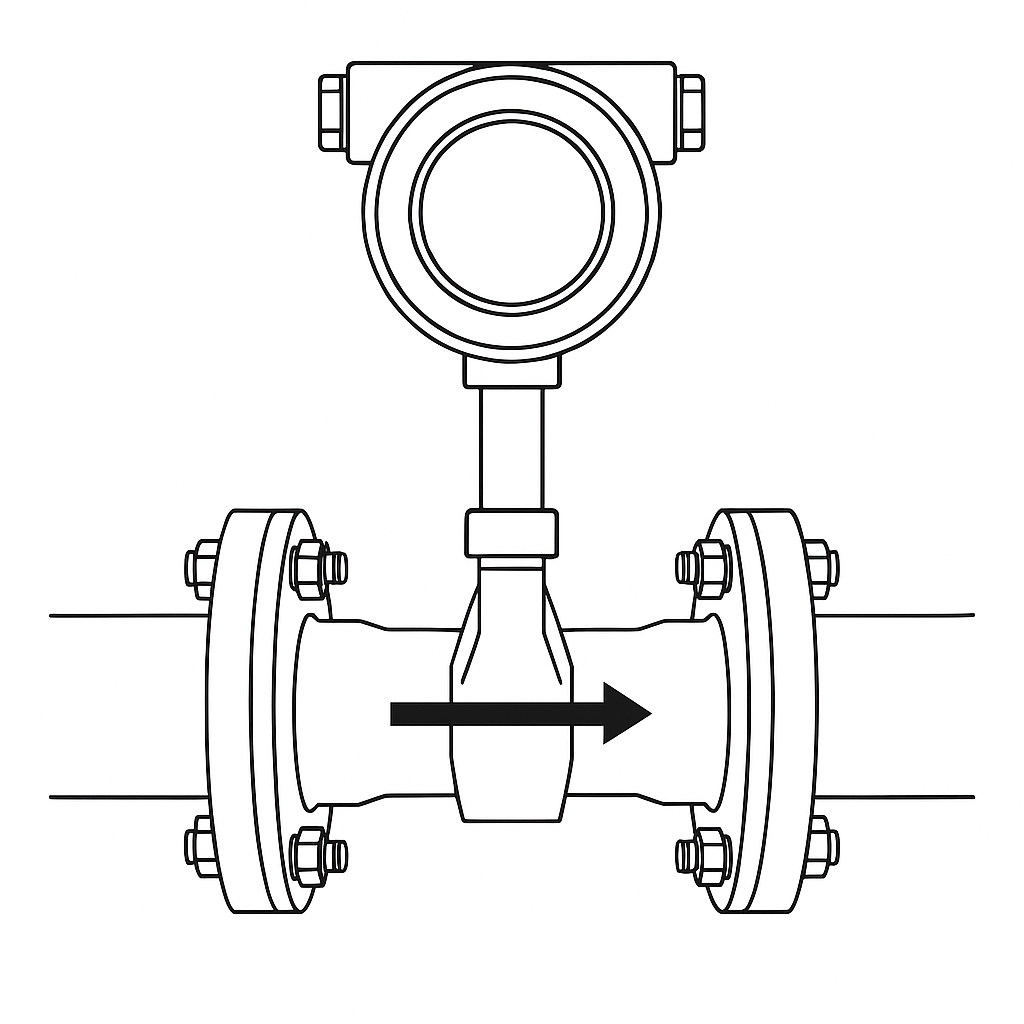

Figure 1: Proper alignment and flange connection schematic

1.2 Installation Location

Straight Pipe Requirements:

Upstream: ≥10D, Downstream: ≥5D (D = pipe diameter)

If upstream has disturbance sources (elbows, valves, reducers): ≥20D upstream + 5D downstream

Avoid Harsh Environments:

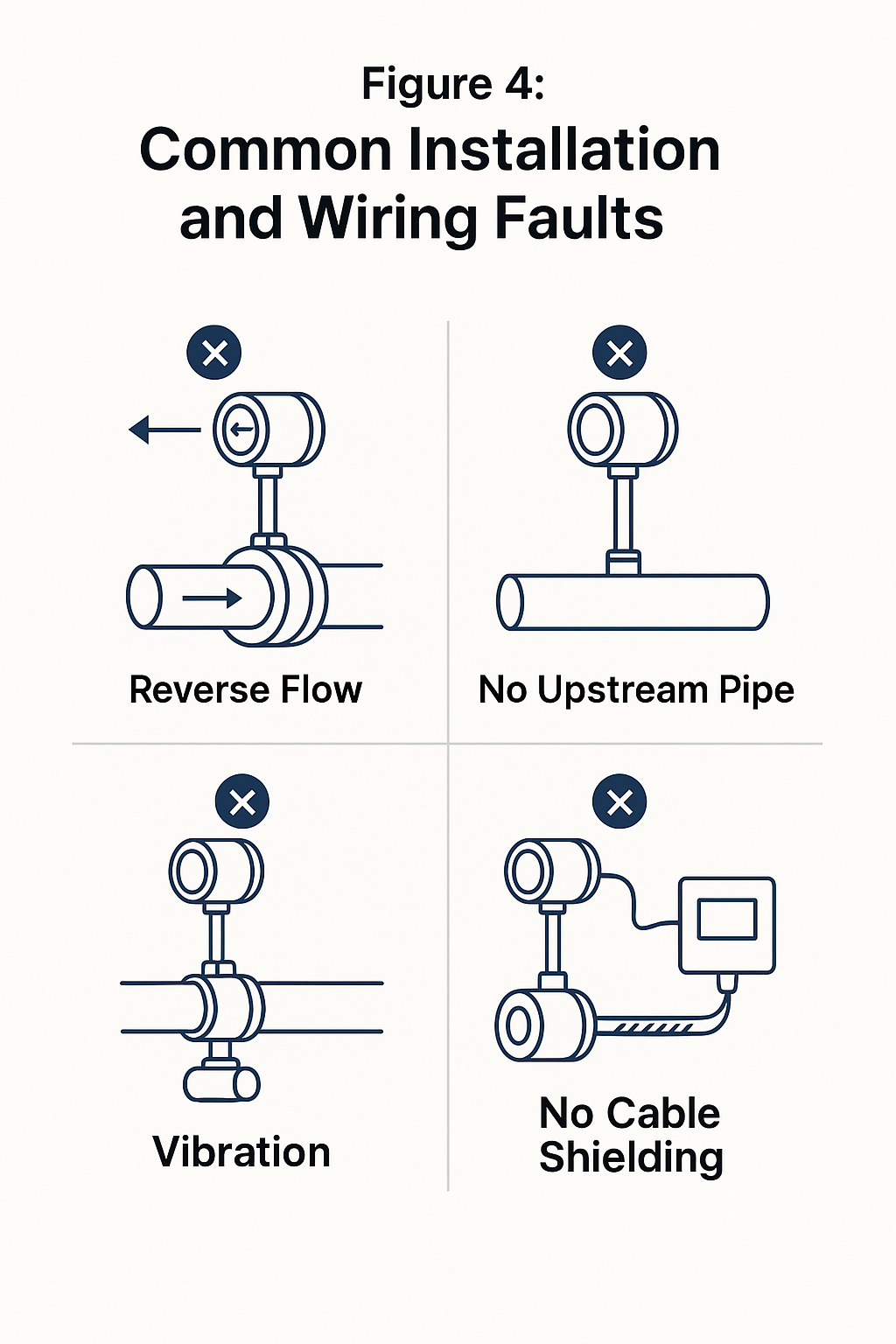

Keep away from vibration sources (e.g., pumps), heat sources, or strong electromagnetic fields (e.g., inverters).

Ambient temp: -20°C to +60°C; Humidity ≤85% RH

Installation Orientation:

Horizontal: Sensor axis parallel to the ground, pipe fully filled.

Vertical: Medium should flow from bottom to top (recommended for liquids).

Inclined: For steam or gas, ensure slope supports condensate drainage.

Figure 2: Installation direction and orientation scenarios

1.3 Installation Procedure

Flange Connection: Ensure coaxial flange alignment; tighten bolts evenly. Gasket must not intrude into the flow path.

Sensor-Converter Wiring: Use shielded signal cables through metal conduits. Keep away from power cables. Ensure correct polarity and grounding resistance ≤10Ω.

Flow Direction: Confirm arrow on housing matches actual flow direction.

1.4 Special Media Considerations

Liquids: Avoid bubbles (install air vents upstream). Vertical bottom-up installation preferred.

Steam: Use insulation, install condensate pots upstream, and trap drains downstream.

Gas: Avoid liquid inclusion. Gas-liquid separators recommended downstream.

2. Routine Inspection and Maintenance

2.1 Daily Inspection

Display Status: Check for abnormal readings, zero drift, or alarms.

Appearance Check: Look for leaks, rust, dirt, or mechanical damage on housing and flanges.

Environment: Verify no abnormal vibration or environmental deviation.

2.2 Periodic Maintenance

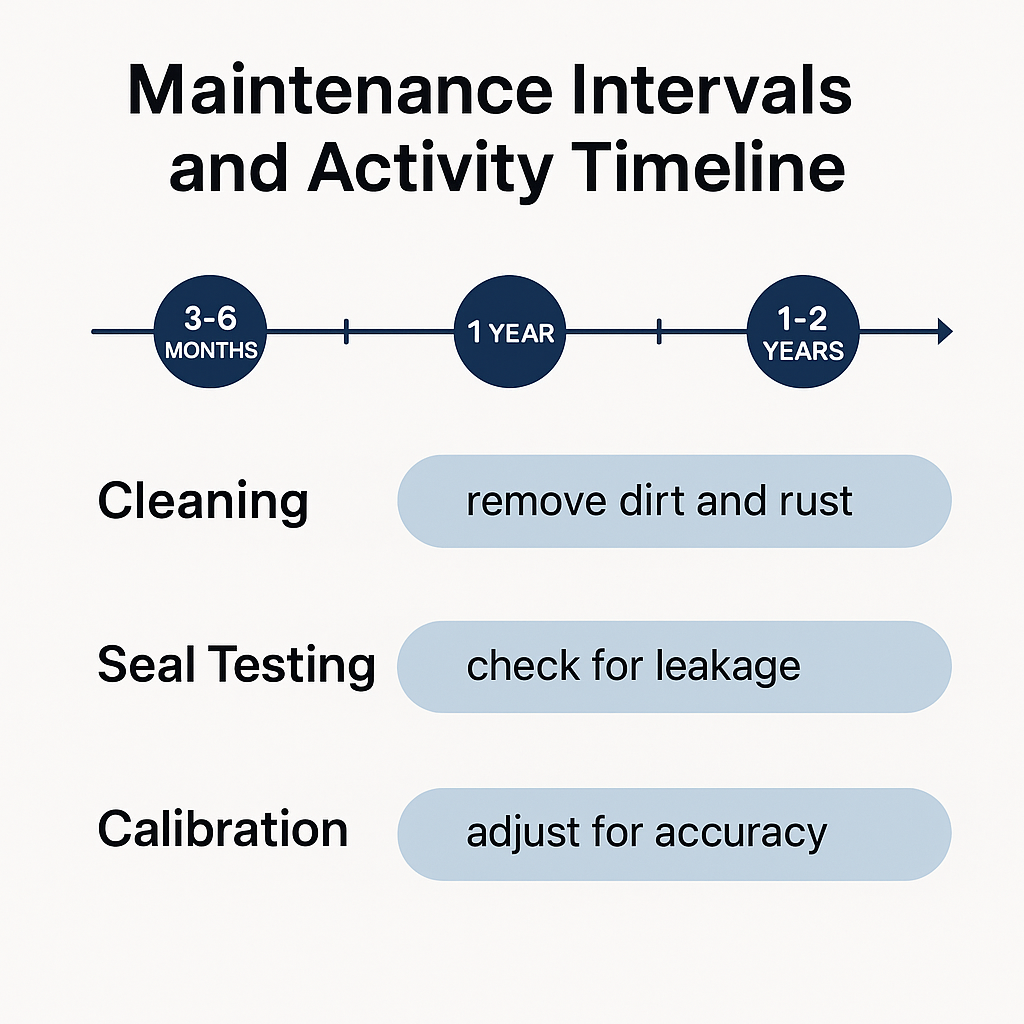

Cleaning (every 3–6 months):

Clean sensor probes and pipe walls with a soft brush or non-corrosive solvent.Corrosion Prevention:

Apply anti-rust paint or grease on exposed metal parts.Leak Test (annually):

Use soapy water on flanges to detect leaks, especially under high-pressure service.Calibration (every 1–2 years):

Perform zero calibration or real-flow calibration. Prefer certified labs for high-accuracy needs.Component Replacement:

Replace aged gaskets, damaged cables, or malfunctioning displays as needed.

Figure 3: Maintenance intervals and activity timeline

3. Common Fault Diagnosis & Solutions

| Issue | Possible Causes | Recommended Solutions |

|---|---|---|

| No flow reading / Weak signal | 1. Loose wiring 2. Power fault 3. Sensor damage | Check wiring, replace power supply or sensor |

| Large deviation in readings | 1. Insufficient straight pipe 2. No temp/pressure compensation | Add flow conditioner, recalibrate with compensation |

| Fluctuating readings | 1. Two-phase flow 2. Pipe vibration 3. Electromagnetic noise | Install air vent/separator, add support, improve shielding |

| Abnormal totalizer jump | 1. Solid particles impacting sensor 2. Converter settings error | Install filter, adjust parameters/filtering time |

Figure 4: Common installation and wiring faults (visuals)

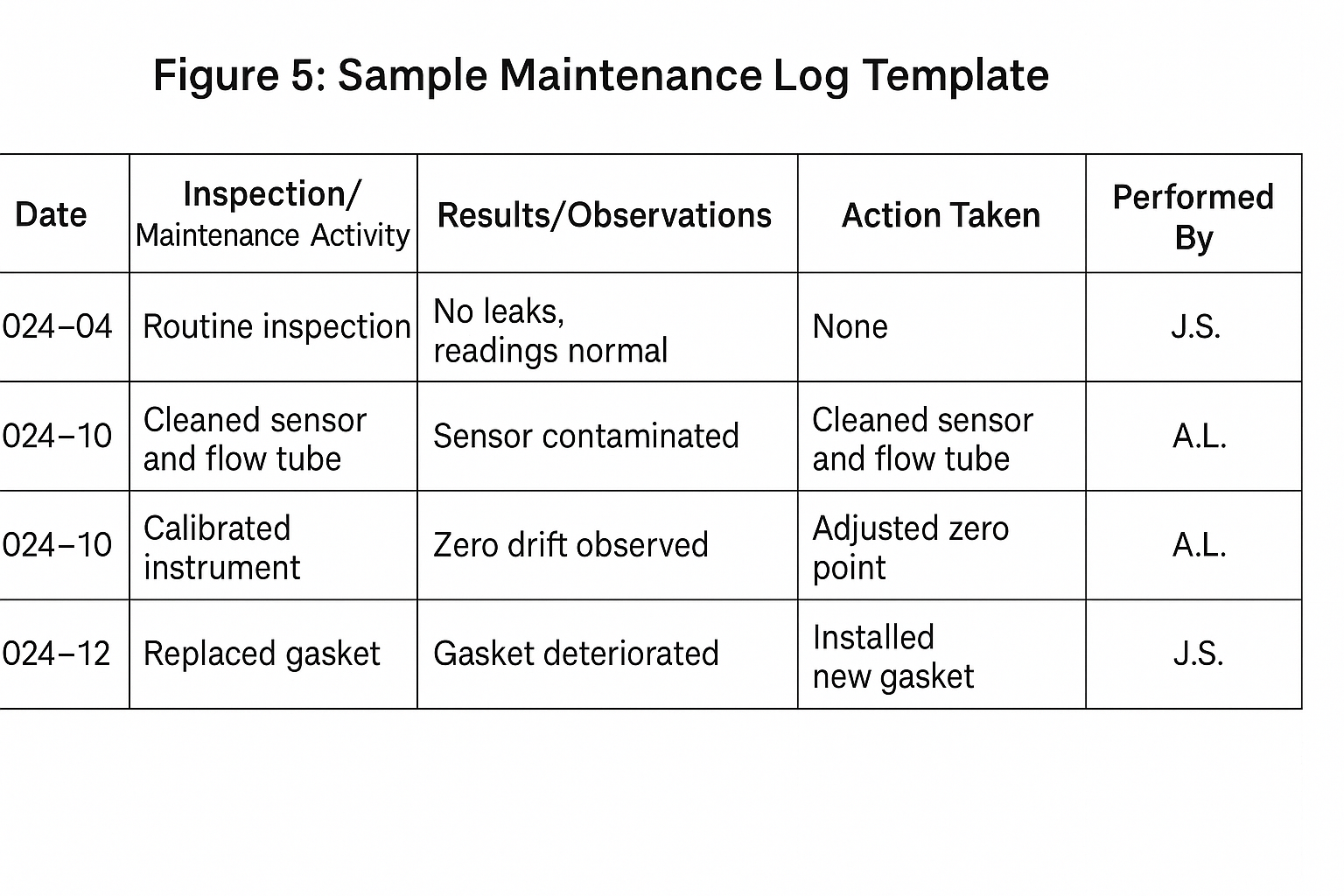

4. Maintenance Records & Log

Maintain a log including:

Dates and descriptions of inspection, cleaning, calibration

Any abnormalities and corrective actions taken

Component replacements and verification records

Figure 5: Sample maintenance log template

5. Safety Precautions

During installation/repair:

Shut off process media, depressurize, and disconnect power. Explosion-proof tools are mandatory in hazardous zones. Never open the housing while powered.At height:

Use safety harness, ensure supervised operation.Chemical media:

Wear protective gear to avoid skin contact or inhalation of vapors.

6. Long-Term Shutdown Care

If the meter is out of service >3 months:

Drain the pipeline; store the sensor in a dry, non-corrosive atmosphere.

Power off the converter, cover with dust-proof hood.

Perform full inspection, calibration, and leak test before reuse.

✅ Conclusion

Through proper installation and scheduled maintenance, the performance and reliability of vortex flow meters can be greatly enhanced. In the event of complex failures (e.g., internal circuit faults or damaged probes), contact the manufacturer’s technical support—unauthorized disassembly is not recommended.