Single flange pressure transmitters are widely used for direct pressure or level measurement in tanks and pipelines. Their measurement accuracy largely depends on correct installation and environmental conditions. This document outlines key installation practices, technical precautions, and maintenance requirements to ensure optimal performance and longevity.

1. Installation Method and Positioning Requirements

Single flange pressure transmitters should be directly mounted to the pipeline or tank wall using a dedicated process flange. The flange surface must remain perpendicular to the pressure direction to ensure proper sealing and accurate transmission.

The transmitter housing can be rotated within the flange without affecting the zero point, as long as the flange interface remains vertical. This design flexibility facilitates easier cable routing and display viewing.

For horizontal flange installations (e.g., on vertical pipelines), care must be taken to compensate for hydrostatic head caused by height differences in the impulse line. In such cases, re-zeroing the transmitter is necessary after installation.

2. Zero Adjustment and Hydrostatic Compensation

When the transmitter is mounted at a different height from the tapping point, especially in level measurement applications, liquid column pressure differences can introduce zero offset. Manual zero calibration or digital trimming should be performed after installation to eliminate this offset and ensure measurement accuracy.

3. Process Pressure and Diaphragm Protection

Always ensure the applied process pressure remains within the rated working range and static pressure limits indicated in the product documentation. Excessive overpressure may permanently damage the sensor.

The diaphragm at the transmitter’s front end is the core pressure-sensitive element. It must be protected from mechanical damage. Do not touch, press, or clean the diaphragm with sharp tools or abrasive materials.

4. Recommended Installation Environment

To ensure long-term stability and reliability, install the transmitter in an area with minimal temperature gradient, low vibration, and minimal mechanical shock. Avoid direct exposure to heat sources, strong magnetic fields, or high-frequency machinery.

When installed outdoors or in corrosive environments, ensure appropriate enclosures and protective measures are applied, such as weather shields or anti-corrosion coatings.

5. Disassembly and Maintenance Notes

Disassembly of the transmitter must only be carried out under atmospheric (zero pressure) conditions. Never attempt to remove the device when pressurized.

All installation, commissioning, and maintenance activities should be performed by qualified technical personnel. Carefully read the product manual before starting any operation, and follow all safety and configuration guidelines.

6. Illustrations (Suggested)

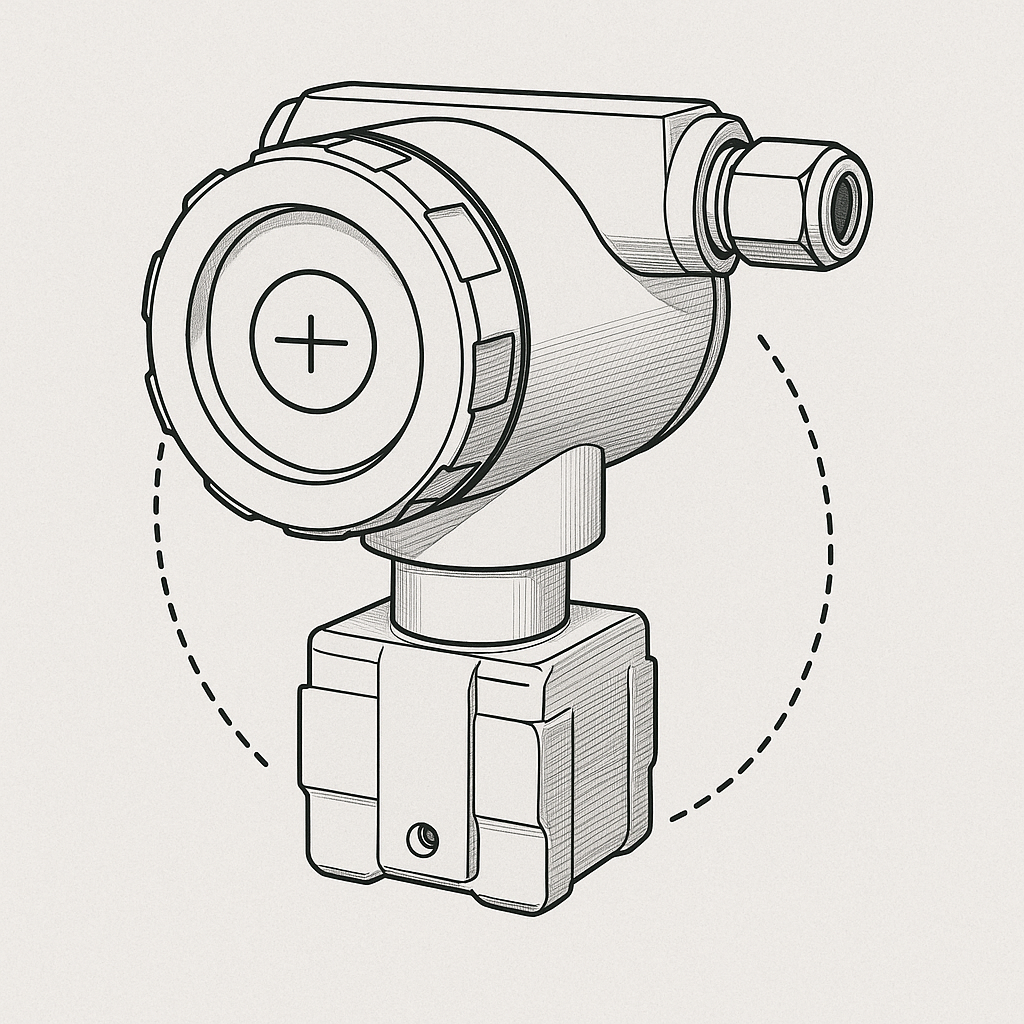

Figure 1: Proper mounting orientation of single flange transmitter on tank wall.

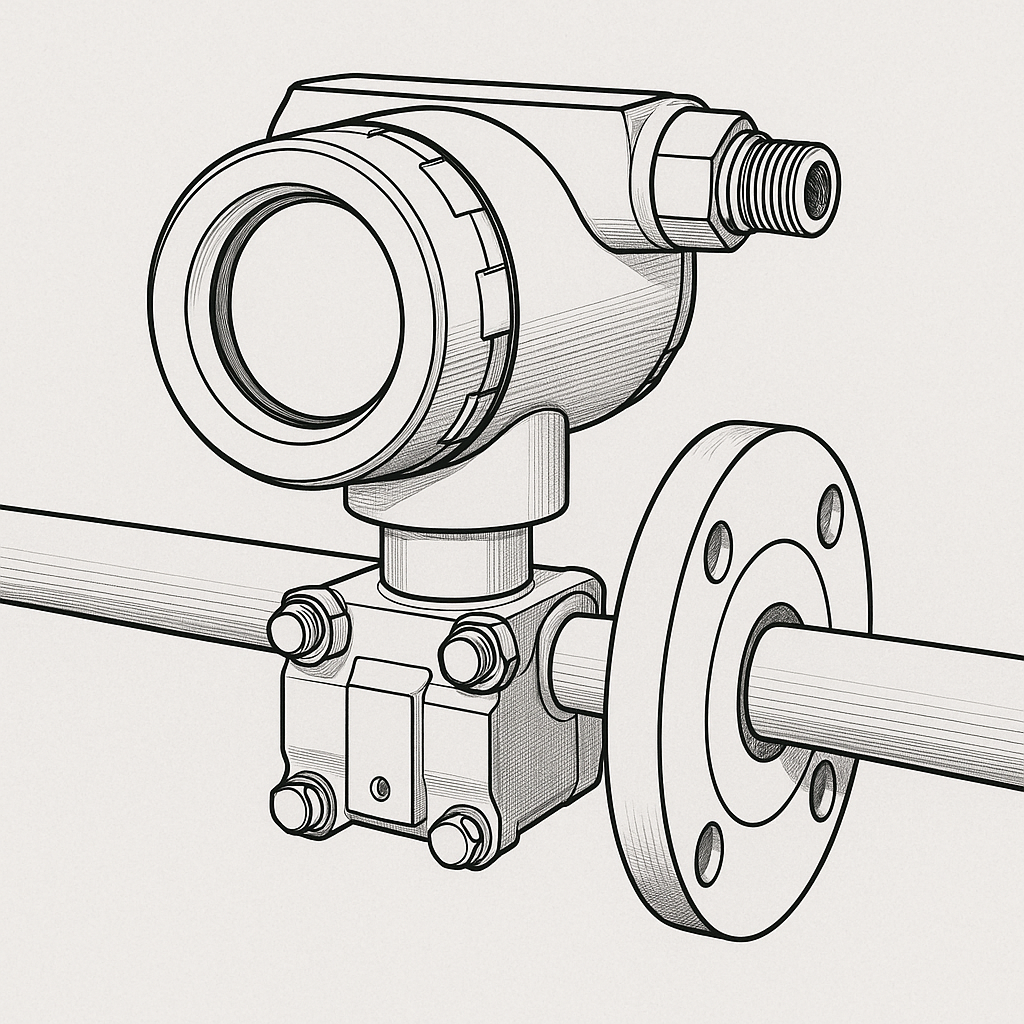

Figure 2: Zero adjustment due to hydrostatic head from height difference.

Figure 3: Protection zone around transmitter diaphragm.

By adhering to these guidelines, users can maximize the operational performance and service life of single flange pressure transmitters in industrial process applications.