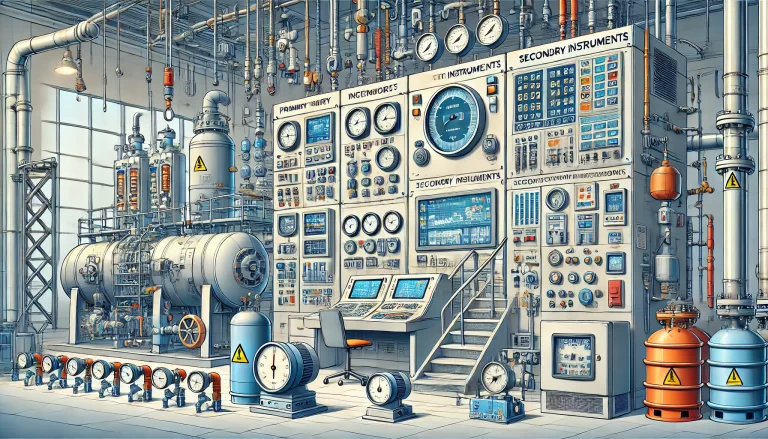

Secondary electrical equipment plays a critical role in monitoring, measuring, controlling, regulating, and protecting primary electrical systems. Unlike primary equipment, it does not directly interact with the main power circuit, but its proper functioning is essential for overall system reliability and safety. This article provides detailed guidelines for inspecting secondary equipment in electrical systems.

Key Considerations for Secondary Equipment Inspection

1. Environmental Requirements

Temperature and Humidity:

Maintain an ambient temperature of 5°C to 45°C.

Ensure relative humidity levels are within 5% to 90% to prevent condensation, which can cause short circuits or corrosion.

Dust and Harmful Gases:

Dust particles can cause static electricity buildup and affect the connectivity of metal contacts, leading to equipment malfunction. In environments with low relative humidity, static electricity is more likely to occur.

Ensure the air is free from corrosive gases such as salts, acids, or sulfides, which accelerate the aging of components and corrosion of metal parts.

2. Ventilation Requirements

Ensure adequate ventilation to dissipate heat generated during equipment operation. For example, devices like the MSR36-40 router rely on a left-in, rear-out airflow design for cooling.

Keep the intake and exhaust vents unobstructed, maintaining a clearance of at least 10 cm.

Install equipment in well-ventilated areas with a functioning air circulation system to prevent overheating.

3. Static Electricity Protection

Static electricity can damage sensitive components within secondary equipment. Proper anti-static measures include:

Grounding: Ensure the equipment and flooring are well-grounded.

Dust Control: Keep the indoor environment clean and dust-free.

Humidity Control: Maintain an appropriate balance of temperature and humidity to reduce static buildup.

Handling Precautions:

Always wear anti-static wrist straps and anti-static clothing when handling circuit boards or modules.

Place removed components such as memory sticks, CF cards, or interface modules face-up on an anti-static workbench or store them in anti-static bags.

Avoid direct contact with circuit components; hold them by their edges.

Using Anti-Static Wrist Straps:

Slip your hand into the wrist strap and tighten it for secure skin contact.

Attach the strap’s locking buckle to the crocodile clip.

Clip the crocodile clip onto the equipment’s grounding terminal.

4. Equipment and Cabinet Requirements

Cabinet Design:

Ensure the cabinet has an efficient ventilation and cooling system.

The cabinet should be sturdy enough to support the weight of the equipment and accessories.

Maintain enough space inside the cabinet to facilitate heat dissipation; allow a minimum clearance of 0.8 meters at the front and back for maintenance purposes.

Installation Space:

The cabinet height should not be less than 3 meters in indoor environments to ensure proper air circulation and accessibility.

5. Maintenance of Components

Routine Cleaning: Regularly clean equipment surfaces to prevent dust accumulation, which can interfere with performance.

Corrosion Checks: Inspect connectors and metallic parts for signs of rust or corrosion, particularly in humid environments.

Connection Integrity: Ensure all plugs, connectors, and cables are securely fastened.

6. Handling Equipment During Inspection

Power Isolation: Before inspecting any device, ensure it is powered off and isolated from the main circuit to prevent accidents.

Component Handling: When removing or replacing parts, use tools specifically designed for electronic components to avoid damage.

Conclusion

Inspecting secondary electrical equipment requires attention to environmental factors, anti-static measures, proper ventilation, and meticulous handling. Following these guidelines helps extend the lifespan of equipment, ensures operational reliability, and minimizes the risk of malfunctions. Regular inspections and preventive maintenance are vital for maintaining the safety and efficiency of electrical systems.