1. Introduction

Flame detectors are critical components of boiler furnace safety supervision systems (FSSS). Their primary function is to monitor combustion status in real time and provide signals once flame instability or extinction occurs, ensuring the timely shutdown of fuel supply.

Among flame detectors, infrared (IR) flame detectors and ultraviolet (UV) flame detectors are the two most widely used types. This article compares their principles, applications, interference resistance, response performance, and service life, while also providing practical guidelines for maintenance and calibration.

2. Working Principles

Infrared Flame Detector

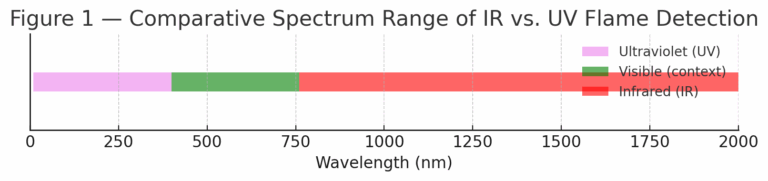

Detects infrared radiation (0.76–1000 μm) emitted during combustion. High-temperature carbon particles and water vapor in the flame radiate infrared waves, which are captured by photodetectors to determine flame presence.Ultraviolet Flame Detector

Responds to ultraviolet radiation (10–400 nm) generated by hydrocarbon combustion reactions. UV sensors such as photomultiplier tubes detect this high-frequency radiation to identify flame status.

3. Application Scenarios

Infrared Detectors

Best suited for diffusion combustion of carbon-rich fuels (coal dust, coke, heavy oil).

Performs reliably in smoky or dusty environments (industrial boilers, coking furnaces, waste incinerators).

Ultraviolet Detectors

Ideal for clean combustion of natural gas, propane, and light oils.

Excellent in systems requiring rapid response (gas turbines, flares).

📊 Table 1 — Comparison of Suitable Fuels and Applications

| Detector Type | Suitable Fuels | Typical Applications |

|---|---|---|

| Infrared | Coal, coke, heavy oil | Boilers, coking furnaces, incinerators |

| Ultraviolet | Natural gas, propane, light oil | Gas turbines, gas boilers, flare stacks |

4. Interference Resistance

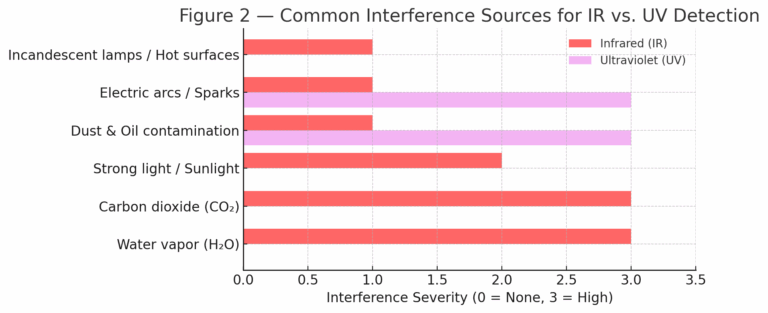

Infrared

✅ Resistant to visible light and furnace wall heat radiation.

❌ Susceptible to interference from water vapor, CO₂, and direct strong light.

Ultraviolet

✅ Minimal environmental background interference; not affected by incandescent lamps or hot surfaces.

❌ Vulnerable to oil/dust contamination and electrical sparks (which emit UV).

5. Response Speed and Service Life

Response Speed

UV: <10 ms (ideal for fast shutdown requirements).

IR: 50–100 ms (better for stable, long-term monitoring).

Service Life

IR: 5–10 years, high-temperature tolerance (>150 °C).

UV: 2–5 years, more sensitive to high temperatures (>80 °C accelerates aging).

6. Typical Applications

Infrared: Coal-fired boilers, coking furnaces, waste incinerators.

Ultraviolet: Gas-fired boilers, biogas flares, gas turbines.

Hybrid IR + UV: Combines strengths of both for maximum reliability in complex environments.

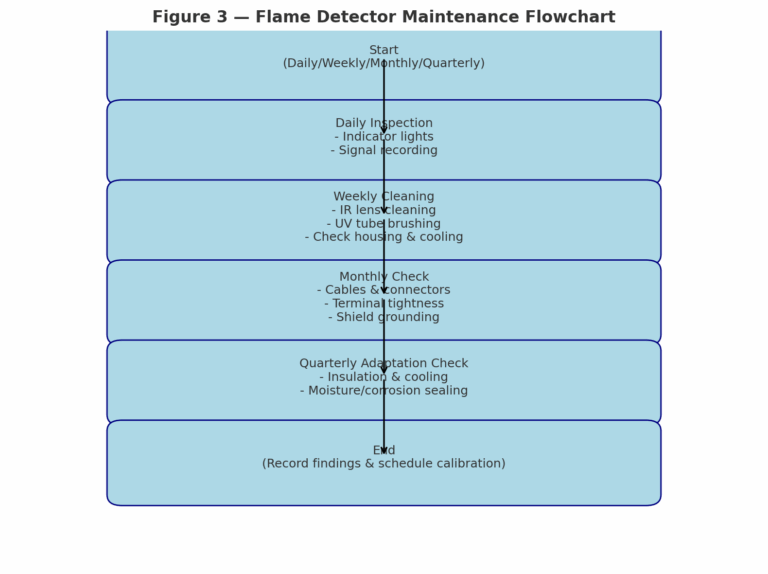

7. Maintenance Guidelines

Routine Cleaning (weekly)

Clean IR sensor lens with alcohol wipes; replace if scratched.

Gently brush UV tubes; remove dust and condensation.

Wiring & Connections (monthly)

Inspect cables for heat damage or corrosion.

Ensure shielded cables are grounded at a single point.

Operational Checks (daily)

Verify indicator lamps and alarms.

Record detector signals; compare with historical data.

Environmental Adaptation (quarterly)

Check insulation, cooling fans, sealing against moisture and corrosive gases.

8. Calibration Procedures

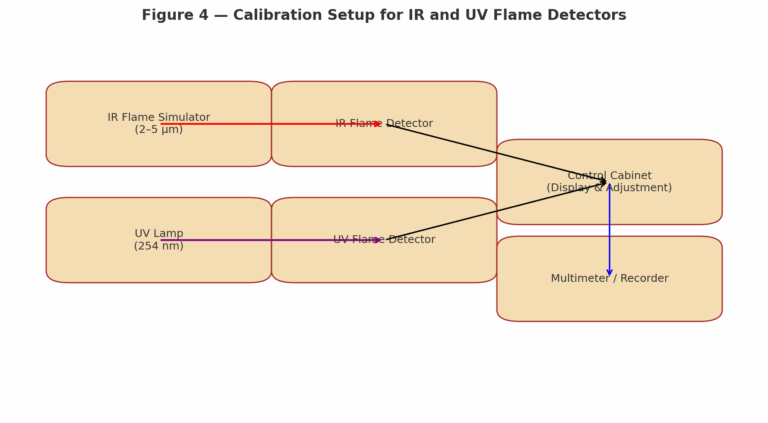

Infrared Calibration

Use flame simulator (2–5 μm IR spectrum).

Adjust thresholds for “flame present” and “no flame” detection.

Ultraviolet Calibration

Use 254 nm UV lamp to simulate combustion.

Adjust gain and zero settings for stable output (4–20 mA).

Hybrid IR + UV Calibration

Calibrate each channel separately, then perform redundancy tests.

Calibration Cycle

Every 6 months, or immediately after sensor replacement/overhaul.

Maintain a calibration logbook with thresholds, values, and environmental conditions.

9. Conclusion

Infrared and ultraviolet flame detectors each have unique strengths:

IR: Longer life, better in dusty and carbon-rich environments.

UV: Faster response, better for clean fuel combustion.

In practice, the choice depends on fuel type, operating environment, and safety requirements. For critical systems, hybrid detectors (IR + UV) are recommended to maximize reliability.