1. Introduction

Industrial Control Systems (ICS) are the backbone of modern industrial production. Their architecture is designed with multiple layers to ensure efficiency, reliability, and stability. This document provides a structured overview of ICS architecture, communication networks, redundancy and security mechanisms, and future development trends.

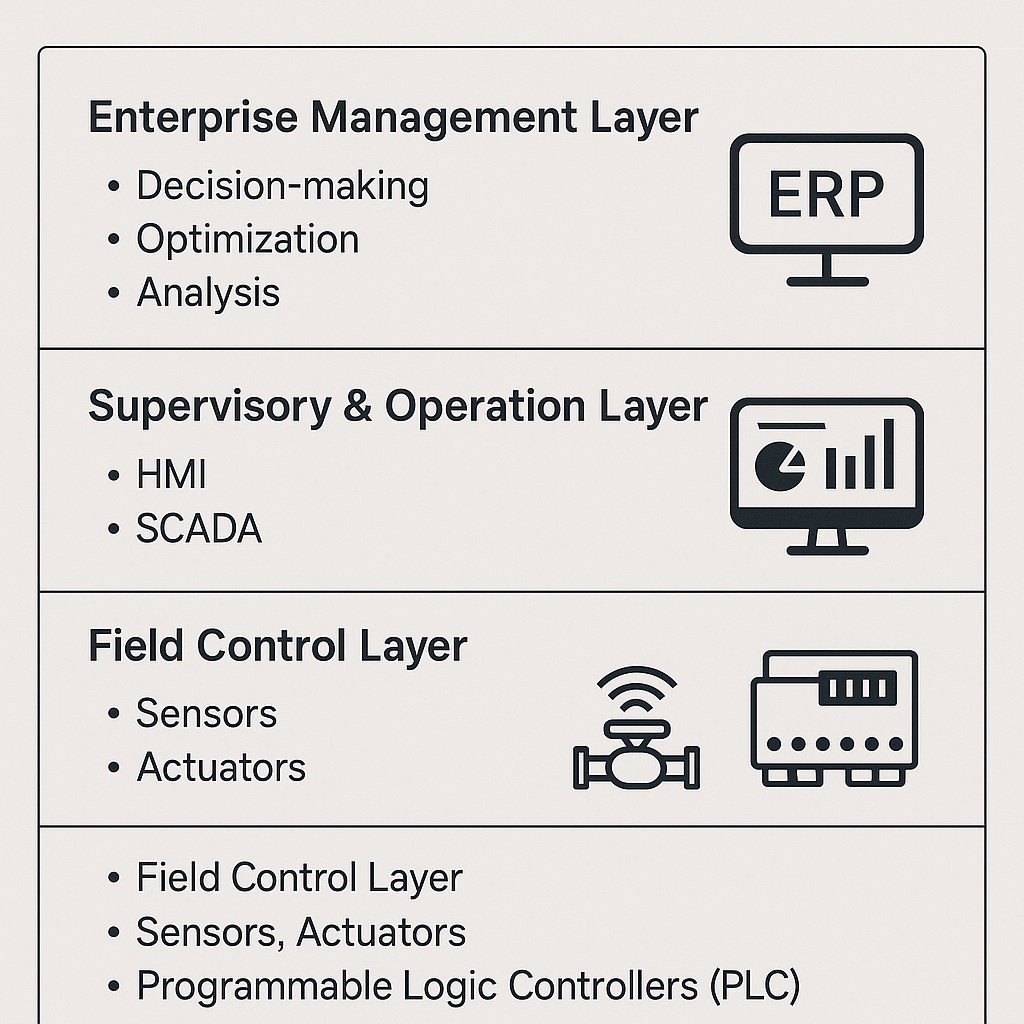

2. Three-Tier Architecture of ICS

2.1 Field Control Layer — The Execution Base

Typical Devices: Sensors, actuators, Programmable Logic Controllers (PLCs).

Main Functions: Collect real-time data (temperature, pressure, flow) and perform immediate control actions (start/stop equipment, adjust valves).

Key Feature: Emphasis on real-time response and reliability, as it directly interfaces with physical processes.

2.2 Supervisory & Operation Layer — The Control Center

Components: Human-Machine Interface (HMI), Supervisory Control and Data Acquisition (SCADA).

Main Functions: Provide operators with a graphical interface for monitoring, coordinate data exchange between field and enterprise layers.

Key Feature: Serves as the central hub for process monitoring and supervisory control.

2.3 Enterprise Management Layer — The Decision Layer

Systems: Enterprise Resource Planning (ERP), Manufacturing Execution Systems (MES).

Main Functions: Analyze production data, optimize scheduling, and enhance efficiency.

Key Feature: Focus on business performance, resource allocation, and remote decision support.

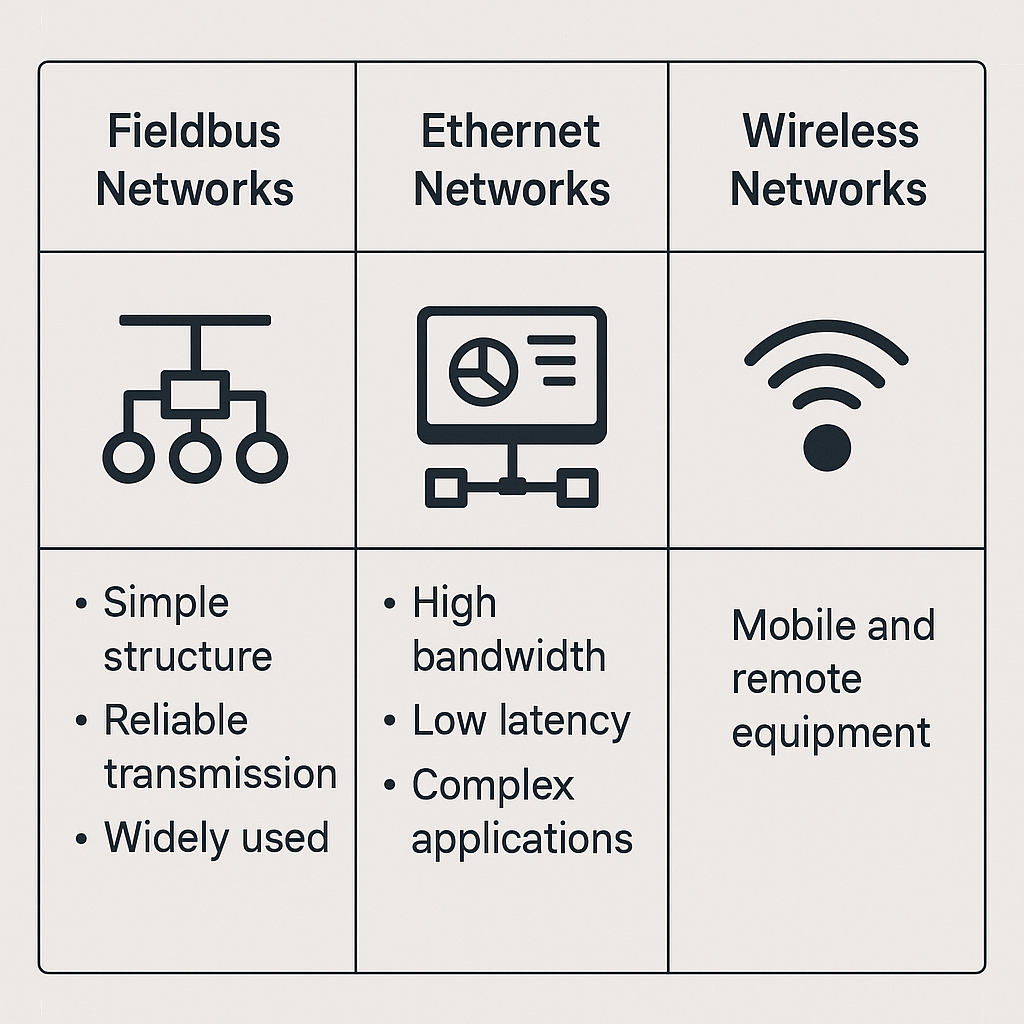

3. Communication Networks in ICS

Seamless collaboration across layers requires robust communication technologies.

3.1 Fieldbus Technologies

Protocols: Modbus, PROFIBUS.

Advantages: Simple structure, reliable transmission, widely adopted at the field level.

3.2 Industrial Ethernet

Examples: EtherNet/IP, Profinet.

Advantages: High bandwidth, low latency, suitable for complex monitoring and management applications.

3.3 Wireless Communication

Examples: 5G, ZigBee.

Application: Mobile equipment and geographically dispersed plants.

Challenges: Lower security; requires robust encryption and protective measures.

4. Redundancy and Security Design

4.1 Redundancy Design

Approach: Configure backup controllers (PLCs) and servers.

Benefit: Ensures continuity—backup units immediately take over in case of primary device failure.

4.2 Network & System Security

Measures: Firewalls, Intrusion Detection Systems (IDS), encrypted data transfer.

Standards Reference: IEC 62443, NIST Cybersecurity Framework.

Objective: Prevent cyberattacks, misoperations, and safeguard industrial data integrity.

5. Future Development Trends

With the rise of Industry 4.0 and Smart Manufacturing, ICS is evolving rapidly:

5.1 Edge Computing

On-site data processing reduces reliance on enterprise servers.

Benefits: Lower latency, improved system responsiveness.

5.2 Cloud Integration

Cloud platforms enable remote maintenance, centralized upgrades, and large-scale data analytics.

5.3 Artificial Intelligence (AI) Integration

Predictive maintenance, anomaly detection, equipment health forecasting.

Supports proactive operations and optimized lifecycle management.

6. Conclusion

The architecture of Industrial Control Systems is built on clear functional layering, robust communication, and reliable redundancy and security mechanisms. As digital technologies advance, ICS are transitioning toward more intelligent, more connected, and more resilient systems, aligning with the goals of Industry 4.0 and smart manufacturing.