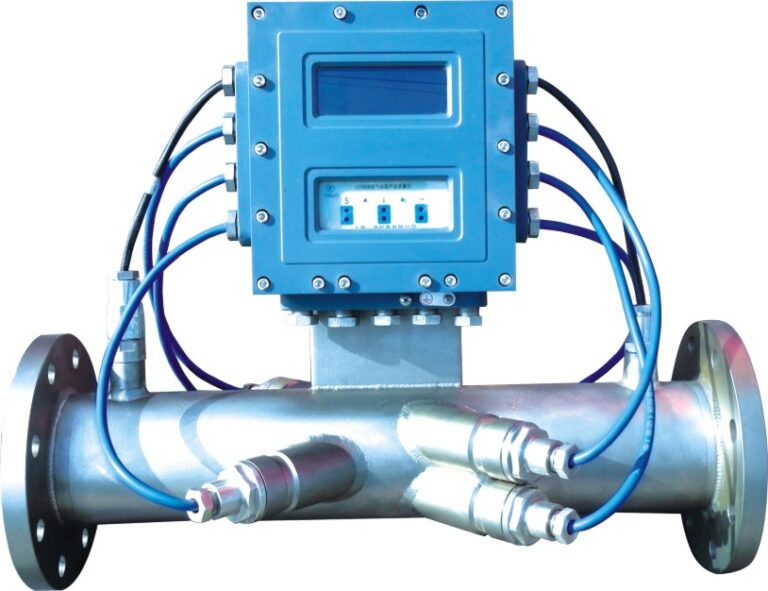

Gas ultrasonic flow meters are advanced instruments used to measure gas flow rates by leveraging the relationship between the speed of ultrasonic waves and the flow velocity of the gas medium. These devices are non-intrusive and highly accurate, making them an excellent choice for various industrial applications, including natural gas distribution, process control, and environmental monitoring. Selecting the right gas ultrasonic flow meter requires a thorough understanding of the specific conditions under which it will operate, as well as the technical characteristics of the meter itself. This article delves into the key considerations that should be evaluated when choosing a gas ultrasonic flow meter for a particular application.

1. Measurement Accuracy and Performance

Precision Requirements

One of the most critical factors in selecting a gas ultrasonic flow meter is its measurement accuracy. The accuracy required depends on the application: for example, custody transfer in the natural gas industry demands extremely high precision (typically ±0.5% or better), while less stringent applications, such as process monitoring, may tolerate lower accuracy.

Gas ultrasonic flow meters generally offer high accuracy due to their non-intrusive nature, which avoids disturbing the flow profile. Advanced models utilize multi-path measurement techniques, where multiple ultrasonic transducers are used to measure flow across several points in the pipe, increasing accuracy by averaging measurements and compensating for any flow disturbances.

Rangeability and Turn-Down Ratio

The turn-down ratio, or rangeability, refers to the range over which the flow meter can accurately measure flow rates. Gas ultrasonic flow meters typically offer wide turn-down ratios, often in the range of 1:10 or greater, making them well-suited for applications where flow rates vary significantly. This high rangeability ensures that the meter can handle both peak and low-demand flow conditions without losing accuracy.

2. Gas Composition and Physical Properties

Types of Gases

The type of gas being measured is crucial when selecting a flow meter, as different gases have varying densities, viscosities, and acoustic properties, all of which can affect the performance of ultrasonic flow meters. Common gases measured include natural gas, compressed air, nitrogen, and oxygen, each with distinct characteristics. The speed of sound in these gases differs, and the flow meter must be calibrated or configured accordingly to provide accurate measurements.

Gas Contaminants and Moisture Content

In real-world applications, gases may contain impurities such as particulates, moisture, or other contaminants that could interfere with the performance of the ultrasonic transducers. These impurities can scatter the ultrasonic waves, leading to inaccurate readings. Therefore, when selecting a meter, it’s important to evaluate its ability to tolerate contaminants or to consider installing filtration systems upstream to ensure the gas remains clean.

3. Pipeline Size and Flow Profile

Pipe Diameter and Meter Configuration

Gas ultrasonic flow meters are available in various sizes to accommodate different pipeline diameters, from small to large pipelines (often exceeding DN200). The pipe size directly influences the selection of the meter, as it must be sized correctly to maintain accuracy and ensure proper installation.

Flow Profile Considerations

The accuracy of an ultrasonic flow meter depends on a stable and fully developed flow profile. Turbulence, swirls, or flow disturbances caused by bends, valves, or other fittings upstream of the meter can result in measurement errors. To mitigate this, some flow meters incorporate multi-path technology, measuring at different angles across the pipe to average out any disturbances. It is also important to ensure adequate straight pipe runs upstream and downstream of the meter to allow the flow profile to stabilize, as recommended by the manufacturer.

4. Operating Conditions

Temperature and Pressure Limits

Gas ultrasonic flow meters are designed to operate within specific temperature and pressure ranges. The operating conditions of the process—such as the gas temperature, ambient temperature, and system pressure—must align with the meter’s specifications. In high-pressure applications, such as natural gas pipelines, it’s essential to select a meter that can withstand the pressure levels without compromising accuracy or safety. Similarly, for high-temperature applications, ensure that the transducers and other components are rated to handle the thermal stress.

Hazardous Environments and Safety Certifications

If the meter is to be installed in a hazardous area, such as in the oil and gas industry or chemical processing plants, it must comply with applicable safety standards. Many gas ultrasonic flow meters are available in explosion-proof configurations, certified according to standards such as ATEX, IECEx, or FM. The selection of an appropriate explosion-proof or intrinsically safe model ensures compliance with safety regulations and mitigates risks in hazardous environments.

5. Signal Output and Integration with Control Systems

Output Signals and Protocols

Modern gas ultrasonic flow meters are equipped with a variety of output options to integrate with supervisory control and data acquisition (SCADA) systems, distributed control systems (DCS), or other industrial automation platforms. Common outputs include analog 4-20mA, digital pulses, and communication protocols like Modbus, HART, or Profibus. When selecting a meter, it is important to ensure that its communication capabilities are compatible with the existing control infrastructure, enabling seamless integration and data transfer.

Data Logging and Remote Monitoring

Many gas ultrasonic flow meters come with advanced data logging capabilities, storing historical flow data that can be analyzed for performance monitoring, diagnostics, and trend analysis. Some models also support remote monitoring, allowing operators to access real-time data and adjust settings from a centralized location. This feature is particularly beneficial for large-scale operations where meters are installed across multiple sites or in hard-to-reach locations.

6. Maintenance and Cost Considerations

Maintenance Requirements

One of the advantages of ultrasonic flow meters is their low maintenance design. Since they have no moving parts, there is less wear and tear, reducing the need for regular maintenance. However, it is important to consider the ease of installation, access to transducers, and any calibration requirements. Some meters are designed with “hot-tap” features, allowing the transducers to be installed or removed without shutting down the process, which can be critical in continuous operations.

Total Cost of Ownership

While ultrasonic flow meters may have a higher initial purchase cost compared to other types of flow meters (such as differential pressure or mechanical meters), their longevity, low maintenance, and high accuracy often result in lower total cost of ownership over the lifespan of the instrument. Additionally, by preventing measurement inaccuracies and minimizing downtime for repairs or recalibration, ultrasonic meters can provide significant cost savings in the long term.

7. Brand Reputation and After-Sales Support

Choosing a Reliable Manufacturer

When selecting a gas ultrasonic flow meter, it is important to choose a reputable manufacturer with a proven track record of quality and performance. Established manufacturers such as Emerson, GE, SICK, and Krohne are known for their high-quality ultrasonic flow meters and offer extensive technical support, training, and after-sales services. Opting for a well-known brand ensures reliability and accuracy, minimizing the risks associated with inferior or unreliable equipment.

After-Sales Service and Calibration Support

Regular calibration is necessary to maintain the accuracy of any flow measurement system. Selecting a supplier with a strong after-sales support network, including calibration services and technical assistance, is essential for the long-term reliability of the flow meter. Furthermore, access to spare parts and timely technical support can greatly reduce downtime and ensure that the flow meter remains in optimal operating condition.

Conclusion

Selecting the right gas ultrasonic flow meter involves careful consideration of the application’s specific requirements, including measurement accuracy, gas properties, pipeline conditions, and operating environment. By understanding these factors and working with a reputable manufacturer, operators can ensure they choose a flow meter that delivers accurate, reliable, and cost-effective performance over the long term. With their high accuracy, low maintenance, and robust design, gas ultrasonic flow meters are well-suited for a wide range of industrial applications, offering a valuable solution for both large-scale and small-scale operations.