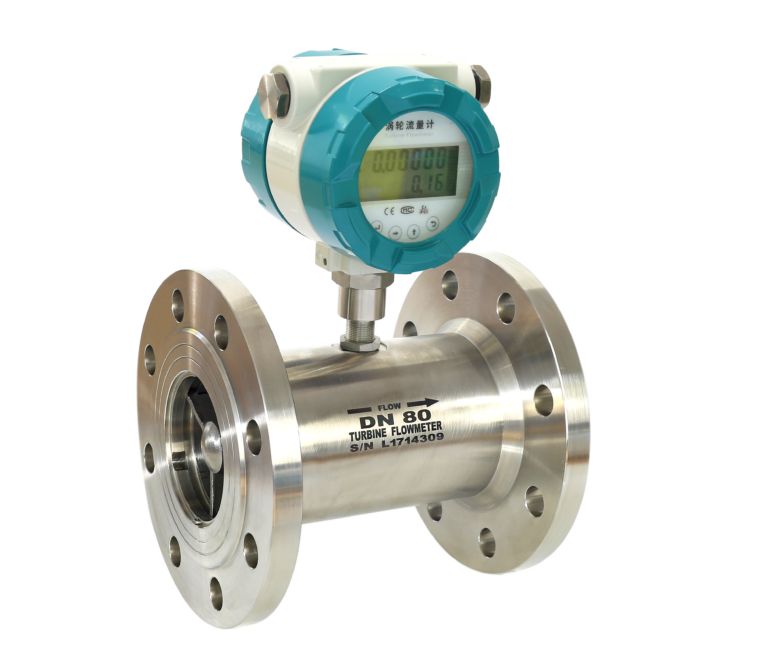

Turbine flow meters are precision instruments used for measuring the flow rate of liquids or gases in various applications. Ordering the correct turbine flow meter is critical to ensuring compatibility with your system and achieving accurate, reliable measurements. This article outlines the key aspects you should consider when placing an order for a turbine flow meter.

1. Provide Detailed Specifications

When ordering a turbine flow meter, it is crucial to provide the supplier with all relevant parameters to recommend the appropriate model and configuration. Key specifications include:

- Measured Medium: Specify whether you will measure a liquid or gas, and provide the exact type of medium (e.g., water, oil, compressed air).

- Flow Rate Range: Define the minimum, maximum, and typical flow rates for your application. Ensure the selected flow meter can handle the entire range with accuracy.

- Temperature and Pressure: Include the operating temperature and pressure ranges of the medium to ensure the meter can handle these conditions without compromising performance.

- Viscosity and Density: If measuring liquids other than water, provide the medium’s viscosity and density, as these properties significantly impact the meter’s performance.

2. Choose Suitable Materials

Material compatibility is critical for the longevity and performance of the turbine flow meter. When ordering, ensure that the materials used in the meter are compatible with the medium being measured:

- Turbine Material: Stainless steel is commonly used for general-purpose applications, while aluminum or engineered plastics may be suitable for specific needs.

- Housing Material: The flow meter housing must be resistant to the medium and environmental conditions. Options include stainless steel, carbon steel, and PVC.

- Sealing Material: Ensure that O-rings and other sealing components are resistant to the medium’s chemical properties, particularly if dealing with corrosive or aggressive fluids.

3. Specify Connection Type and Size

The connection type and size must match your existing pipeline to facilitate seamless installation. Important considerations include:

- Connection Type: Common options include threaded, flanged, or quick-connect couplings. The choice depends on the system design and application.

- Connection Size: Match the meter’s nominal diameter (DN) with the pipeline diameter to ensure proper installation and avoid turbulence that may affect accuracy.

- Straight Pipe Requirements: Confirm the required lengths of upstream and downstream straight pipe sections to achieve stable and accurate measurements.

4. Determine Output and Communication Needs

Modern turbine flow meters often feature electronic outputs and advanced communication options. When ordering, specify:

- Signal Output: Choose from pulse, 4-20mA analog, or frequency signals based on your system’s compatibility.

- Communication Protocols: Determine whether your system requires MODBUS, HART, or other digital communication standards.

- Power Supply: Clarify whether the flow meter should be battery-powered, externally powered (e.g., 24V DC), or solar-powered.

5. Clarify Accuracy Requirements

Accuracy levels vary across different turbine flow meter models. Define your precision requirements based on your application:

- Standard Applications: For non-critical applications, a standard accuracy of ±1% or ±2% may suffice.

- High-Precision Needs: For applications such as chemical dosing or custody transfer, opt for a high-accuracy meter with ±0.5% or better.

6. Address Specific Operating Conditions

For specialized environments or applications, you may need specific configurations. Communicate these needs clearly when ordering:

- Explosive Environments: If the meter will be installed in hazardous areas, ensure it meets explosion-proof certifications such as ATEX or IECEx.

- Sanitary Standards: For food, beverage, or pharmaceutical applications, select a sanitary turbine flow meter with smooth surfaces and CIP/SIP compatibility.

- Temperature Extremes: For high-temperature or cryogenic applications, specify a flow meter designed to handle extreme operating conditions.

7. Ensure the Supplier Offers Quality Assurance

Choosing a reliable supplier with robust quality assurance processes is as important as selecting the right flow meter. Consider the following:

- Certifications: Verify whether the supplier has ISO, CE, or other relevant certifications.

- Warranty and Support: Ensure the flow meter comes with a warranty and that the supplier offers installation guidance, calibration, and after-sales support.

- Experience and Reputation: Work with a supplier that has proven experience in your industry and positive customer feedback.

8. Additional Features to Consider

Depending on your application, you may require additional features to enhance functionality:

- Data Logging: Flow meters with built-in data storage can record historical flow rates for analysis and reporting.

- Onsite Display: Integrated displays allow users to view real-time flow data directly on the device.

- Alarm Features: Some meters offer alarms for flow rates outside the predefined range, improving safety and process control.

Example of an Order Specification

When placing an order, prepare a detailed specification document to ensure clear communication with the supplier. For example:

- Measured Medium: Water

- Flow Range: 1 m³/h to 10 m³/h

- Operating Temperature: 5°C to 80°C

- Operating Pressure: Up to 10 bar

- Material Requirements: Stainless steel housing, PTFE seals

- Connection Type: Flanged, DN50

- Signal Output: 4-20mA

- Accuracy: ±0.5%

- Environment: Indoor, non-hazardous

- Additional Features: Onsite LCD display, data logging capability

Conclusion

Ordering a turbine flow meter involves more than selecting a standard model. By carefully defining your requirements and working closely with a trusted supplier, you can ensure that the flow meter meets your application’s specific needs. Attention to details such as material compatibility, operating conditions, and communication protocols will result in a reliable, accurate, and long-lasting solution.