Natural weather phenomena such as wind, rain, lightning, and stray electricity can significantly impact field instrumentation. These effects span mechanical, electrical, and environmental domains, potentially resulting in measurement inaccuracy, device failure, or even catastrophic damage. This document outlines the risks and provides comprehensive protective strategies.

1. Impact of Wind

1.1 Mechanical Damage

Strong winds may cause vibration, displacement, or even detachment of outdoor instruments such as anemometers or exposed pressure transmitters. Insecure installations may suffer from loosened connectors, cracked housings, or internal component instability due to sustained oscillations.

1.2 Environmental Interference

Wind alters the surrounding airflow, impacting flow-based or pressure-based instruments (e.g., differential pressure transmitters, airflow meters), which may result in measurement fluctuation or inaccuracies.

✅ Protection Measures

Reinforced Mounting: Use high-strength brackets or U-bolts designed to withstand local maximum wind speeds (e.g., typhoon-grade for coastal areas).

Vibration Dampening: Install rubber pads or spring shock absorbers between the device and mounting base.

Streamlined Enclosures: Adopt aerodynamic designs or wind shields to reduce wind resistance and direct impact.

Flow Stabilization: Install flow straighteners or diffusers upstream of flow/pressure sensors.

2. Impact of Rain

2.1 Water Ingress and Short Circuits

Rainwater may penetrate poorly sealed enclosures (e.g., cable glands, housing seams), leading to short circuits, corrosion, or insulation degradation.

2.2 Corrosion and Aging

Rainwater—especially acid rain—can corrode terminals, metal enclosures, and deteriorate plastic housings, shortening equipment lifespan.

2.3 Measurement Errors

Humidity and temperature sensors exposed to rain may suffer from water film interference, leading to elevated readings or thermal distortion.

✅ Protection Measures

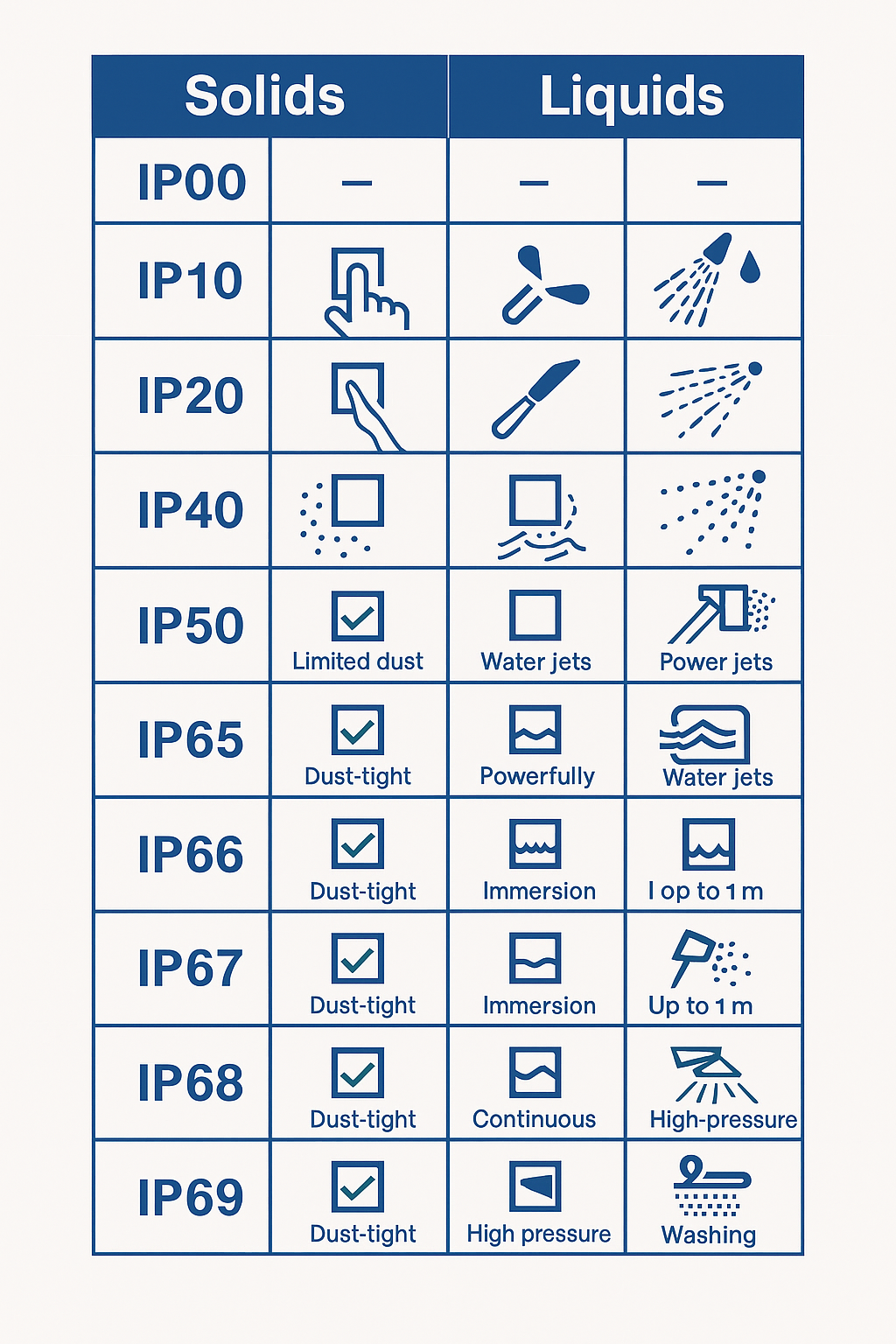

Sealing and IP Rating: Outdoor instruments should comply with IP65 or higher. Use silicone gaskets, waterproof glands, and tilted housing designs to shed water.

Material Selection: Use 316 stainless steel, engineered plastics (e.g., PPS), or coated surfaces to resist corrosion.

Cable Routing: Ensure cables descend vertically at entry points to prevent capillary backflow. Use downward-facing cable glands.

Sensor Protection: Apply hydrophobic coatings or use ventilated sensor hoods to isolate elements from direct rain contact while ensuring airflow.

3. Impact of Lightning

3.1 Direct Strike Damage

A direct lightning strike introduces massive current and heat, which can destroy internal chips, PCBs, or transformers.

3.2 Induced Surges

Nearby lightning strikes can cause surge voltages via electromagnetic induction through power or signal lines, damaging diodes, capacitors, or ICs.

3.3 Electromagnetic Interference

Lightning-induced electromagnetic pulses (EMP) may cause data transmission errors or device freeze, especially in sensitive electronics.

✅ Protection Measures

Lightning Protection System (LPS): Install air terminals (lightning rods) and ensure devices are within the protected radius (calculated via the rolling sphere method).

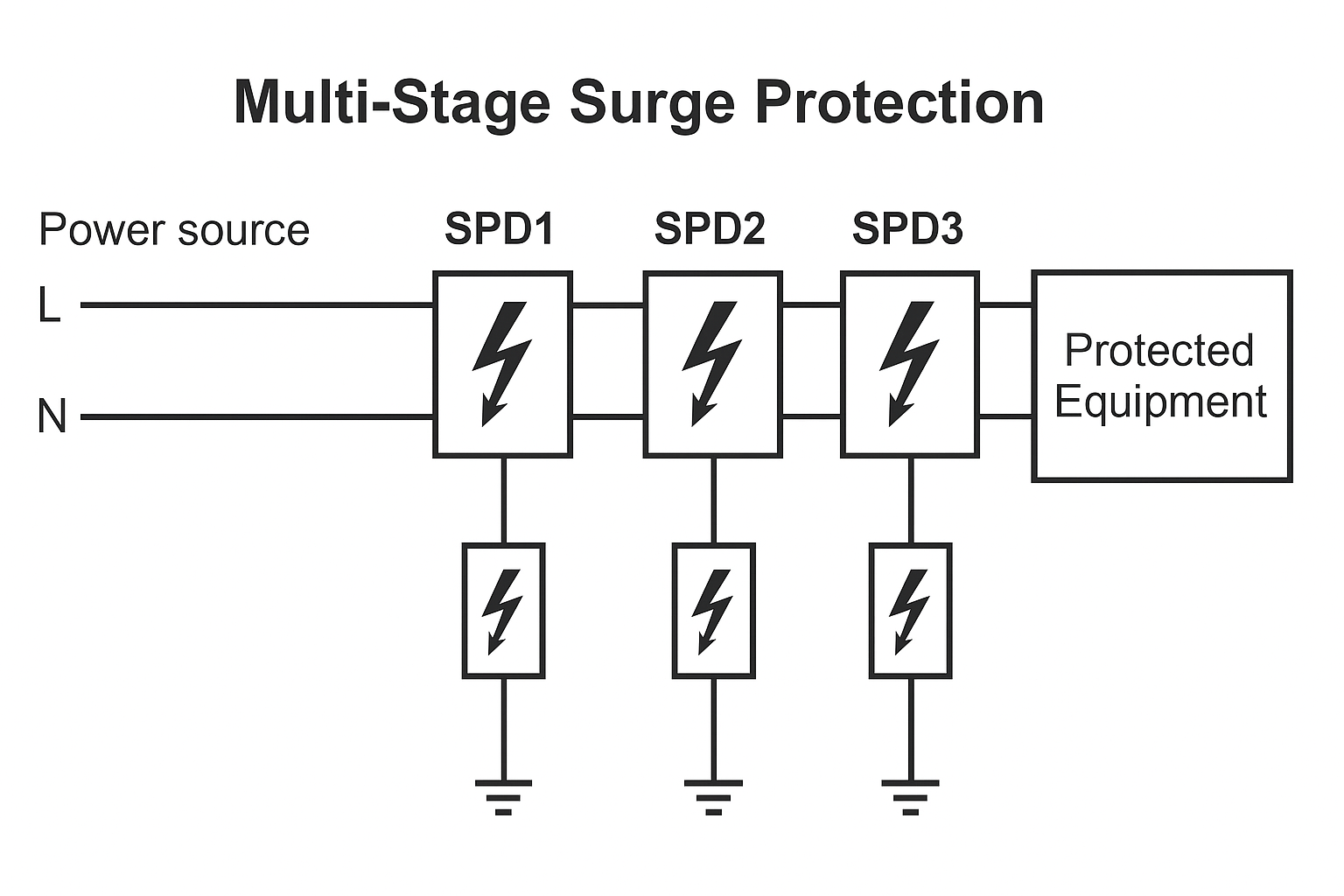

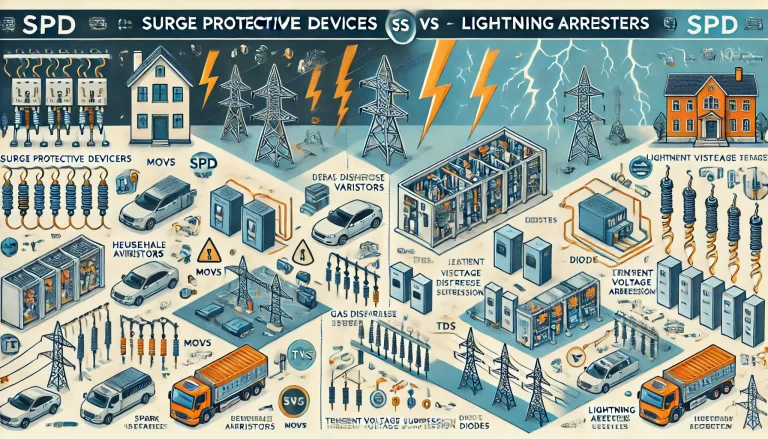

Surge Protection Devices (SPD): Use multi-stage SPDs on power and signal lines. Select devices rated for ≥40kA (Type 1) and ≥20kA (Type 2) discharge capacity.

Shielded Enclosures: Install equipment in grounded metal cabinets forming a Faraday cage (ground resistance ≤4Ω).

Signal Line Protection: Install SPDs tailored to RS485, 4–20 mA, or other signal protocols. Use shielded twisted-pair cables and ground both ends of the shield.

Grounding System Optimization: Separate instrument grounding from lightning and power grounding. Use a ring-type ground grid with ≥0.8m deep electrodes (resistance ≤4Ω).

4. Impact of Static and Stray Currents

4.1 Electrostatic Discharge (ESD)

In dry environments, static may accumulate on surfaces or personnel. Discharge can damage sensitive CMOS components or cause signal interference.

4.2 Stray Current Corrosion

Stray currents from nearby high-power equipment or improper grounding may flow through instrument metal structures, causing electrochemical corrosion.

✅ Protection Measures

Static Discharge Paths: Ground all metal structures using conductors with ≥6 mm² cross-section. Use anti-static wrist straps during maintenance.

Environmental Control: Install humidifiers or use anti-static flooring in dry rooms to reduce ESD risk.

Electrical Isolation: Use insulation pads between instruments and metallic pipelines or structures. Where not possible, apply equipotential bonding.

Cathodic Protection: For buried instruments, apply sacrificial anodes or impressed current methods to prevent corrosion.

5. Integrated Protection Strategy

5.1 Site Selection and Layout

Avoid installing instruments on mountaintops, open fields, or next to tall structures.

Prefer sheltered positions (e.g., under eaves) and avoid flood-prone or wind tunnel zones.

5.2 Smart Monitoring and Maintenance

Equip key instruments with environmental monitoring modules (temperature, humidity, lightning counters).

Schedule annual inspections before storm seasons, including:

Ground resistance measurement

SPD aging test

Waterproof integrity check

5.3 Redundancy and Anti-Interference Design

Implement “hot standby” or redundancy configurations for critical instruments.

Use signal filtering and validation algorithms to suppress weather-induced signal anomalies.

Conclusion

Instrument protection against wind, rain, lightning, and electrical anomalies requires a multi-layered strategy combining:

Structural measures: Strong mounting, water-sealed enclosures

Electrical protections: Surge arresters, grounding, shielding

Environmental design: Placement, material choice, corrosion resistance

For outdoor instruments, a comprehensive configuration such as lightning rod + shielded cabinet + SPD + waterproof seals ensures long-term reliability under harsh conditions. By standardizing design and implementing proactive maintenance, industrial sites can significantly reduce downtime and protect asset integrity in severe weather environments.