In the application areas of the food, medicine, and brewing industries, from the perspective of hygiene, high-temperature steam needs to be regularly used to clean and disinfect the process pipelines and instruments during the process, and the pipeline joints including flowmeter sensors must not have Residual medium to prevent bacteria from multiplying. Therefore, IDF (International Dairy Federation) stipulates the quick coupling form of the food industry pipeline standard. The sanitary flowmeter sensor uses an IDF connector or a clamp-type connection connector that meets the requirements.

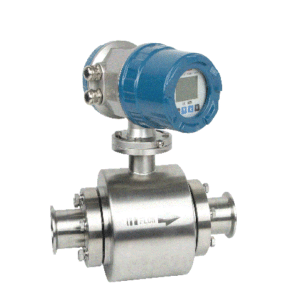

At the same time, in order to withstand frequent washing and prevent the rust of the instrument housing, the housing of the general sanitary sensor is made of stainless steel. Figure 3-40 shows a sanitary electromagnetic flowmeter. It must be noted that the sensor needs frequent high-temperature cleaning and cold water scouring, and its lining should have good thermal shock resistance. Therefore, a better measure for sanitary sensor applications is to add metal mesh to PFA injection molding. Of course, the use of industrial ceramic linings has better thermal shock resistance.

Sanitary flow meters are often used for milk and beverage filling. Due to frequent filling switches, accurate measurement is required, a higher excitation frequency meter is required, and the converter has the function of quantitative signaling and a response time of less than 0.2s.