A device that converts physical measurement signals or ordinary electrical signals into standard electrical signals for output or can be output in the form of communication protocols.

Generally divided into: temperature/humidity transmitters, pressure transmitters, differential pressure transmitters, liquid level transmitters, current transmitters, electrical quantity transmitters, flow transmitters, weight transmitters, etc.

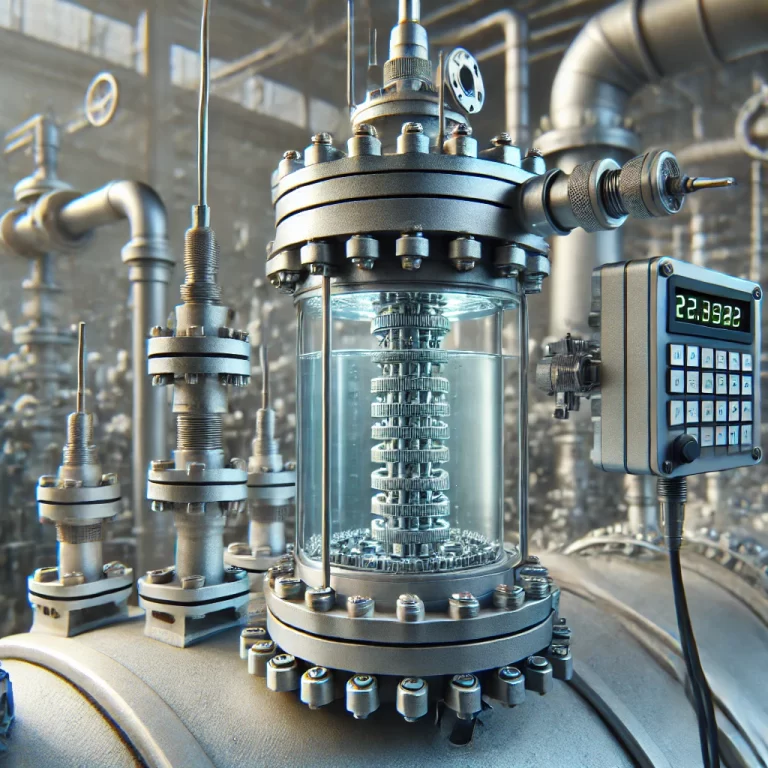

The hydraulic transmitter measures the pressure at the bottom of the liquid level, converts it into the liquid level height according to the medium density, and outputs it with 4-20MA, which is convenient for the control system to monitor and control. The hydraulic transmitter is an extension and development of the pressure transmitter technology.

It is based on the principle that the pressure generated by liquids with different specific gravities at different heights is in a linear relationship, and can accurately measure and transmit the volume, liquid height, and weight of water, oil, and paste.

The hydraulic transmitter works due to the flow of liquid medium. When liquid medium flows through the transmitter, the pressure of the liquid will act on the hydraulic transmitter, and then it will be transmitted to the silicon diaphragm after a certain medium flow.

At the same time, the other side of the diaphragm will also be affected by the pressure of the reference end. In this way, the pressure at both ends of the diaphragm is unbalanced, which will produce a stress.

The stress will cause the diaphragm to be subjected to different forces, that is, one end is subjected to pressure and the other end is subjected to tension. In addition, the strain gauges are placed in different areas, so that the two teams of strain gauges are connected to form a non-static bridge. The formation of this bridge will increase the output signal.

In order to reduce the impact of ambient temperature on the hydraulic transmitter, the bridge will use a constant current for power supply. When the external liquid pressure changes, the output voltage inside the hydraulic transmitter will also change.

This change will be converted into a corresponding current signal after being amplified by the internal components. After compensation, the current of the hydraulic transmitter will produce a standard output signal.

Hydraulic transmitters are widely used in various industrial automatic control environments, involving many industries such as oil pipelines, water conservancy and hydropower, railway transportation, intelligent buildings, production automatic control, aerospace, military industry, petrochemicals, oil wells, electric power, ships, machine tools, hydraulic machinery, etc.