Introduction

Unstable or fluctuating load cell readings can be frustrating—especially when your process depends on consistent, accurate force or weight measurements.

Whether you’re dealing with analog or digital output, sudden signal jumps, or noisy values, this article walks you through a structured troubleshooting checklist to identify and fix the root cause quickly and confidently.

1. Define the Symptom First

Before diving into hardware or cabling, clarify the nature of the instability:

| Symptom Type | Possible Cause Type |

|---|---|

| Random spikes | Electrical noise / EMI |

| Gradual drifting | Temperature, moisture, creep |

| Zero shifting after unload | Mechanical binding or overload |

| Constant oscillation | Vibration or signal noise |

A clear symptom = a faster fix.

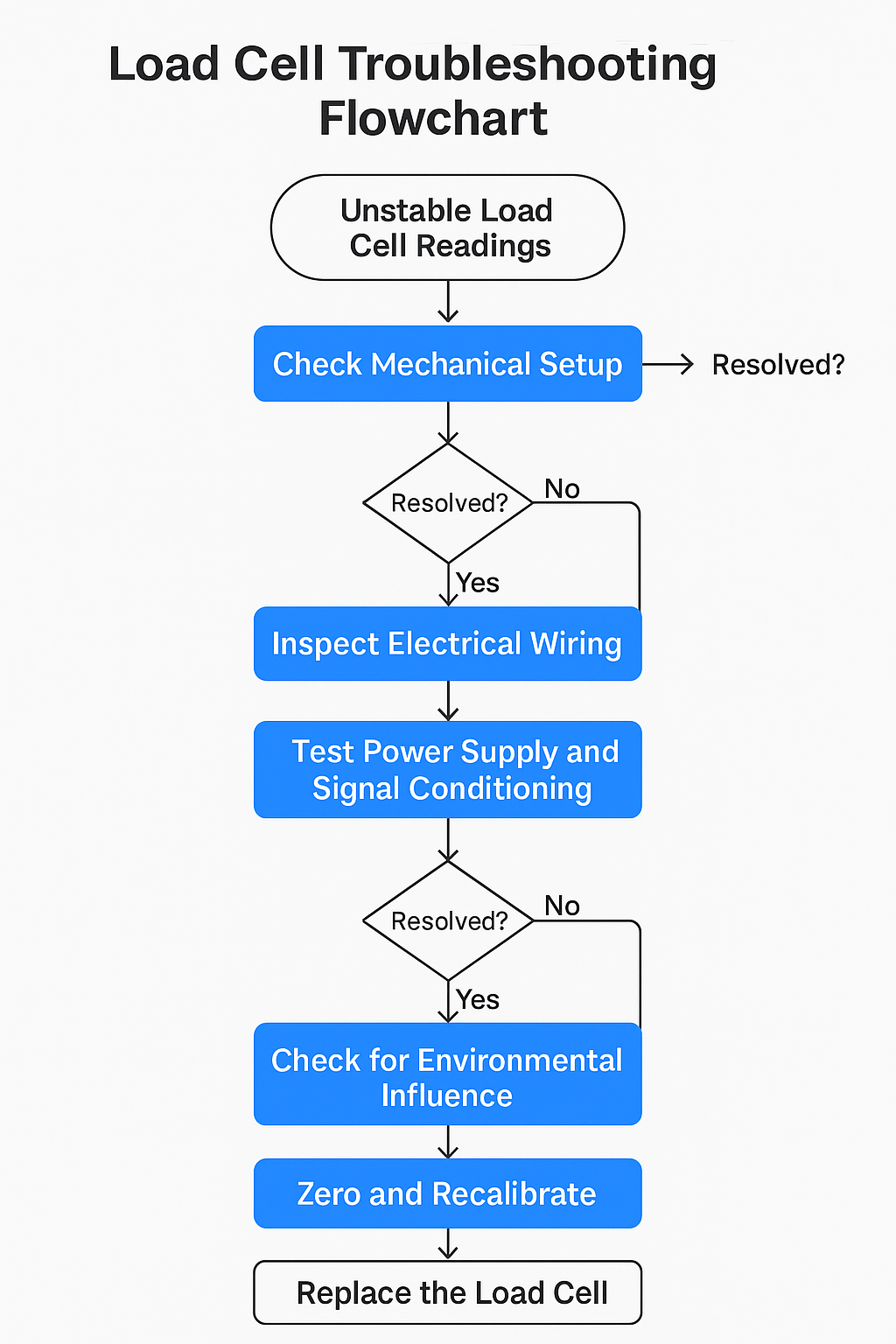

2. Step-by-Step Troubleshooting Guide

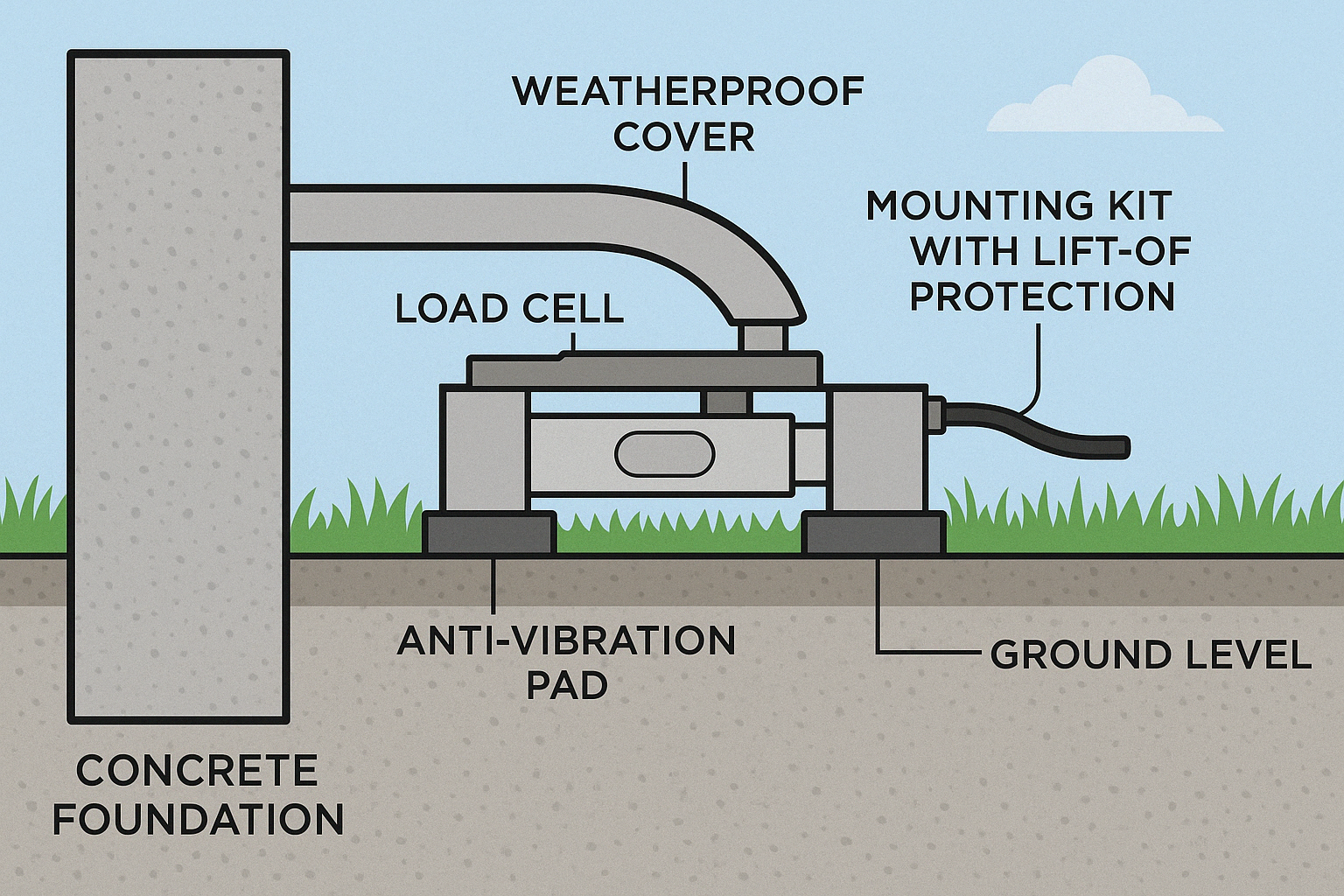

✅ Step 1: Check the Mechanical Setup

Ensure the load cell is properly mounted: flat, rigid, aligned

Look for side loads, tilt, or external mechanical stress

Confirm no looseness or obstruction in the mounting kit

Verify the load is centered and free from vibration or pulsation

✅ Tip: Try unloading the system. If the output doesn’t return to zero consistently, the issue is likely mechanical.

✅ Step 2: Inspect the Electrical Wiring

Look for damaged, pinched, or twisted cables

Check for proper grounding of the signal cable shield (ground one side only)

Avoid routing signal cables near motors, inverters, or high-voltage lines

✅ Tip: A temporary “test cable” routed away from other electronics can help isolate noise issues.

✅ Step 3: Test Power Supply and Signal Conditioning

Confirm stable and clean excitation voltage (typically 5V–10V DC for mV/V systems)

Replace or test the signal amplifier or transmitter if applicable

If using digital output (e.g., RS485), verify termination resistors and Modbus timing

✅ Tip: Use a multimeter or oscilloscope to monitor voltage drift or instability in real time.

✅ Step 4: Check for Environmental Influence

Are the readings affected by temperature changes (e.g., after startup)?

Is the system exposed to moisture, condensation, or water washdowns?

Are nearby motors or welders operating when noise occurs?

✅ Tip: Try isolating the sensor by switching off adjacent machines temporarily.

✅ Step 5: Zero and Recalibrate

Perform a zero or tare operation and see if the reading stabilizes

If the output shifts after loading/unloading, recalibrate the system

In older systems, sensor drift may indicate the need for recalibration or replacement

3. Bonus Checklist: Common Causes and Fixes

| Problem Symptom | Most Likely Cause | Recommended Fix |

|---|---|---|

| Readings spike randomly | EMI or unshielded cabling | Use shielded cable; add ferrite filters |

| Zero shifts over time | Thermal drift or overload history | Re-zero and verify thermal conditions |

| Readings oscillate | Vibration or poor grounding | Isolate system; improve mechanical damping |

| Output doesn’t return to zero | Mechanical friction or misalignment | Check mounting, supports, and parallel loads |

| Signal disappears entirely | Cable or amplifier failure | Test wiring continuity; swap amplifier |

4. When to Replace the Load Cell

If the sensor:

Fails zero tests repeatedly

Shows inconsistent readings even under controlled conditions

Has visible damage, moisture ingress, or deformation

…it may be time for replacement. Load cells do degrade over time, especially in harsh or high-cycle environments.

Conclusion

Unstable load cell readings are usually solvable—but only if you approach the issue systematically.

Start with mechanical alignment, verify electrical connections, rule out environmental noise, and don’t hesitate to recalibrate. A calm, methodical process will save you hours of guesswork and help get your system back on track quickly.

Stable signals start with good habits.