An operations-first playbook for APC engineers and decision-makers

Executive summary

Advanced Process Control (APC) is not tied to any single industry. Whether you’re running petrochemicals, fluorochemicals, blending, fertilizers, or non-ferrous metallurgy, the same foundations apply: material and energy balances, operations knowledge automation, and multi-variable constraint management. The fastest way to deliver value across unfamiliar processes is to start from how operators actually run the plant, then formalize those actions into simple, robust control logic.

1) The core idea: operations first, process specifics second

Across sectors, plants are governed by the same conservation laws:

Material balance: Accumulation = In − Out ± Generation/Consumption

Energy balance: Accumulation = In − Out + Heat − Work ± Reaction

APC succeeds when we translate operator decisions (mode changes, line-ups, trims, overrides) into automation that holds production near constraints with minimal manual intervention. That matters more than deep chemistry expertise on day one. In practice:

Treat the unit as a dynamic system with inputs (manipulated variables, MVs), outputs (controlled variables, CVs), and constraints.

Capture the control authority switching logic operators use (which loop is in charge under which condition).

Coordinate multiple MVs to optimize a single economic objective while respecting all limits.

2) Common myths—and what actually works

Myth 1: Only process licensors can do the best APC.

Reality: APC projects are largely non-standard and benefit from specialized control know-how, agile scoping, and on-site tuning. Deep chemistry knowledge helps, but the lift comes from modeling, constraint handling, and commissioning discipline.

Myth 2: Bigger supplier = better APC.

Reality: Large firms may have small APC teams and rigid delivery models. What matters is method, tooling, and repeatable project hygiene, not logo size.

Myth 3: You must have an identical past project.

Reality: Many units are niche or one-off. What transfers is the engineer’s ability to extract operating logic and package it into robust control structures.

3) A cross-industry APC method that scales

Step A — Discover operations truth

Shadow operators across shifts; collect operational narratives (“When feed swings, we first… then we…”).

Mine alarm and event logs to pinpoint recurring interventions.

Define a minimal but complete list of CVs, MVs, measured disturbances (DVs), hard/soft constraints, and interlocks.

Step B — Quantify dynamics, simply

Use plant tests or routine disturbances to get FOPDT/second-order step responses for SISO pairs.

Rank MV→CV paths by controllability (gain, delay, RGA if multivariable) and drop weak paths early.

Keep models as simple as possible (linear in the small, with schedule or gain-switching across regimes).

Step C — Architect the control layers

Regulatory layer (DCS): clean, well-tuned PIDs with selectors (high/low) and overrides; solid anti-windup.

Supervisory APC: multivariable coordinator (rule-based or MPC) that:

Tracks CV targets while pushing against constraints safely.

Coordinates multiple MVs to a single economic objective (throughput, quality, energy).

Implements control authority switching between modes/units.

Soft sensors (optional): simple estimators (mass/energy balances, inferentials) to reduce analyzer delay.

Step D — Encode operator know-how

Convert “if/then” actions into explicit state logic (operating modes, permissives, inhibits).

Make mode transitions observable and reversible; log reasons for every automatic handover.

Step E — Commission, then iterate

Start with a Minimum Viable APC (few high-value CVs, tight constraint logic).

Commission in guarded ranges; prove stability; widen envelopes.

Institutionalize change management: versioned specs, rollback plans, and operator training.

4) Control design patterns you’ll reuse everywhere

Constraint controllers with selectors: e.g., temperature loop cascaded to fuel valve with high-selector from pressure protection.

Split-range or shared MVs: smoothly apportion work between steam and recycle or between two heaters.

Decoupling/coordination: simple static decouplers can remove 70–90% of cross-coupling without full MPC.

Gain scheduling: switch model/weights by throughput or recipe.

Override protection: always separate safety interlocks from APC; APC must fail safe and release authority cleanly.

5) What to measure and promise (KPIs)

Define before/after metrics and acceptance criteria the client understands:

Variability reduction: e.g., CV standard deviation ↓ 20–50%.

Constraint proximity: average distance to hard constraint ↓ with zero violations.

Throughput/energy: throughput ↑ at fixed quality, or energy per unit ↓ at fixed rate.

Manual interventions: operator setpoint changes and mode flips ↓ significantly.

Stability/robustness: no oscillation, graceful recovery after trips, clean bumpless handover.

Tip: pick KPIs you can compute from historian data without extra instrumentation.

6) Supplier selection—evaluate method, not memorabilia

Use this five-question checklist instead of chasing identical references:

Operations-first scoping: Do they start from alarms/events and shift logs?

Modeling pragmatism: Can they justify simple models and show when they’ll schedule/gain-switch?

Constraint rigor: How do they prove no hard-limit violations during upsets?

Authority switching: Is mode logic explicit, testable, and documented?

Sustainment plan: Do they hand over tuning rules, test scripts, and rollback procedures?

If a bidder can demonstrate these with one or two past case studies (even from different industries), you’re likely in safe hands.

7) Lightweight case vignettes (cross-industry)

Blending (oil products): Coordinated ratio/quality control reduced octane give-away and smoothed tank changeovers; operators stopped “chasing” analyzer lag.

Fluorochemicals: Reactor temperature and feed coordination held conversion at target under feed purity swings; constraint selectors protected condenser duty.

Ammonia/Fertilizer: Steam/recycle split-range kept synthesis loop stable during upstream load changes; variability reductions opened extra throughput.

(These patterns generalize; the chemistry differs, the control logic rhymes.)

8) Operating model and sustainment

Documentation: one-page control narrative per CV/MV (purpose → logic → limits → failure behavior).

Training: short operator drills—“what you’ll see, when it takes control, how to take it back, why.”

Health monitoring: daily APC status tile (in-control %, number of overrides, last 24 h violations).

Lifecycle: scheduled re-tests after turnarounds, feed/product changes, instrument maintenance.

9) Pitfalls to avoid

Over-modeling early; keep it simple until stability is proven.

Embedding safety logic inside APC (keep SIS/ESD independent).

Ignoring sensor quality and analyzer delays (add filtering, inferentials, or sampling plans).

“Black box” deployments without operator buy-in.

No rollback plan; every change must be reversible in seconds.

Conclusion

Cross-industry APC is absolutely feasible when you anchor on operations analysis, simple but sound dynamics, and explicit constraint/authority logic. Chemistry and equipment matter, but the decisive factor is your ability to simplify, structure, and automate how the plant is actually run—so operators intervene less and production stays closer to its economic limits, safely.

Appendix — Quick templates

A. Minimal variable list (fill-in)

CVs: ___, ___, ___

MVs: ___, ___ (limits: ___ to ___; rate limits: ___/min)

DVs: feed rate ___, ambient ___, upstream pressure ___

Hard constraints: T ≤ ___, P ≤ ___, motor load ≤ ___

Soft constraints: quality spec ≥ ___, utility cost ≤ ___

Modes: Warm-up / Normal / High-rate / Transition / Shutdown

B. Acceptance test script (excerpt)

Step feed +X% → CV settles within Y min, overshoot ≤ Z%.

Push toward temperature limit → no violation; selector engages; bumpless handback.

Analyzer upset → inferential holds; no oscillation; alarms as designed.

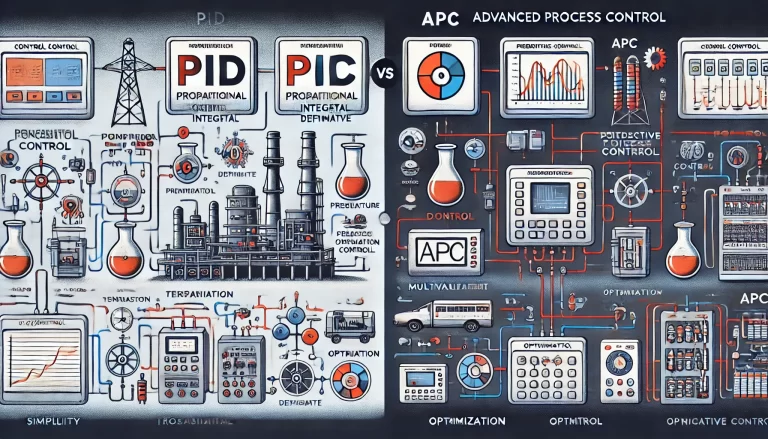

C. Suggested figures for your designer

“From operations to APC” workflow (events → knowledge → control logic).

Layered control architecture (DCS PID → selectors/overrides → supervisory APC).

Authority switching state diagram (modes and transitions).

Constraint handling schematic (CV targets vs. hard/soft limits).

Before/after variability plot (histogram or run chart).