1. Introduction

Radar level transmitters have become increasingly popular in industrial measurement due to their non-contact nature and adaptability to various conditions. While ultrasonic sensors are also common, radar devices dominate in versatility and reliability across open tanks, sealed vessels, and diverse materials like liquids, slurries, and solids.

However, with the market flooded with radar models operating across different frequency bands, selecting the right one can be overwhelming. This article summarizes real-world experience from over 20 years in instrumentation maintenance to help you make a better-informed choice.

2. Low-Frequency Radar (6 GHz – 10 GHz)

Key Features:

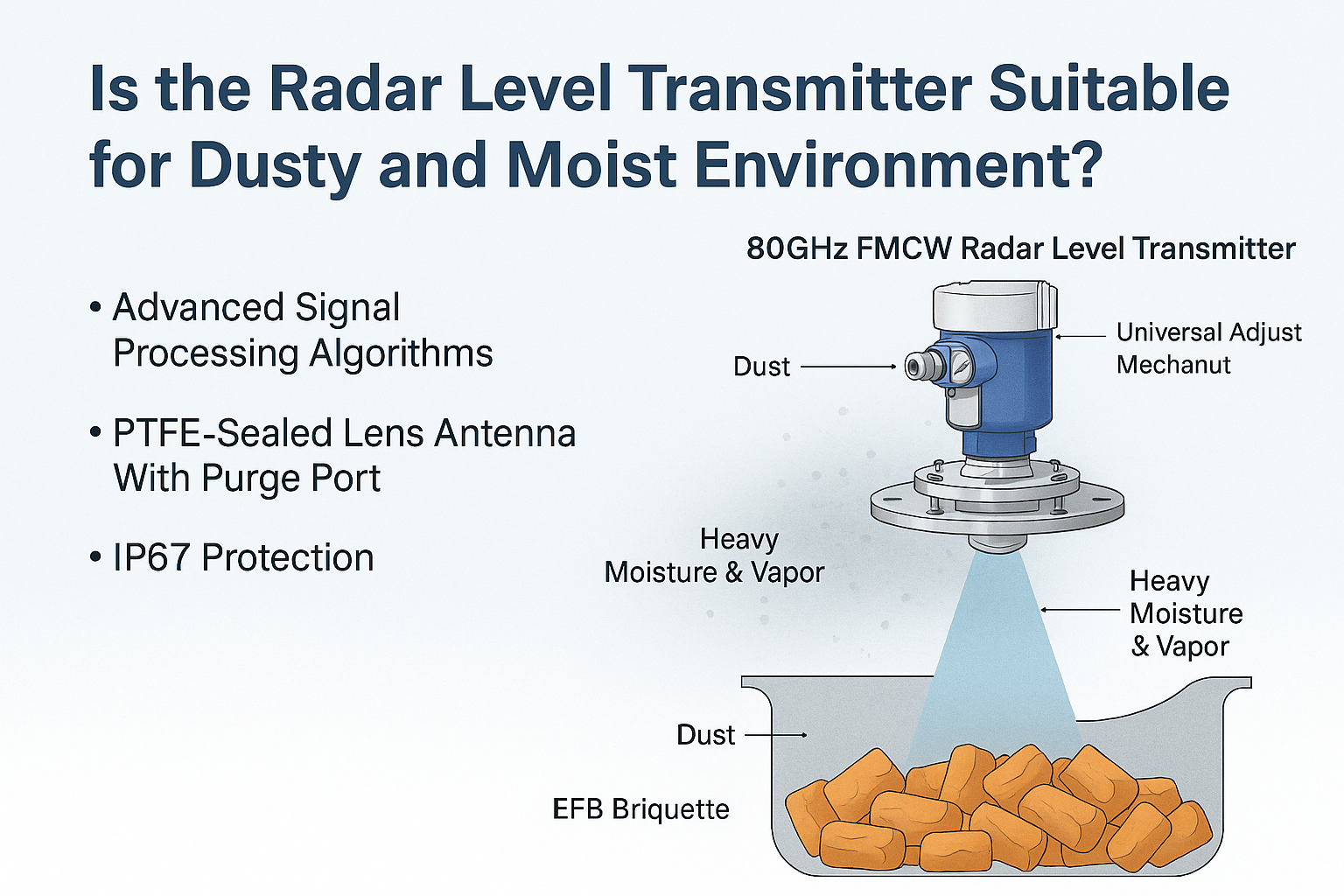

Excellent penetration through steam, dust, and foam

Ideal for harsh environments (e.g., ash silos, cement hoppers)

Cost-effective and reliable

Limitations:

Wide beam angle results in lower measurement precision

Prone to signal scattering from agitators or internal tank structures

Recommendation: Best used in harsh, dusty, or high-moisture environments. Often paired with a stilling tube or strategic installation angle to stabilize readings.

3. Mid-Frequency Radar (24 GHz – 26 GHz)

Key Features:

Balanced performance and cost

Suitable for petrochemical tanks, chemical vessels

Reasonable accuracy under moderate conditions

Limitations:

Susceptible to heavy vapor interference

Might require frequent probe cleaning or reinstallation

Recommendation: A practical choice for standard industrial applications with minimal vapor interference. Avoid using in highly condensed or humid environments without protective measures.

4. High-Frequency Radar (76 GHz – 81 GHz)

Key Features:

Extremely narrow beam angle

Millimeter-level accuracy

Excellent for small or narrow tanks, pharmaceutical and high-value material storage

Limitations:

Sensitive to foam and suspended matter

Requires careful installation and calibration

Recommendation: Perfect for applications demanding high precision. Ensure installation is performed by experienced personnel. Consider modern versions with Bluetooth or remote configuration for convenience.

5. Multi-Frequency Hybrid Solutions

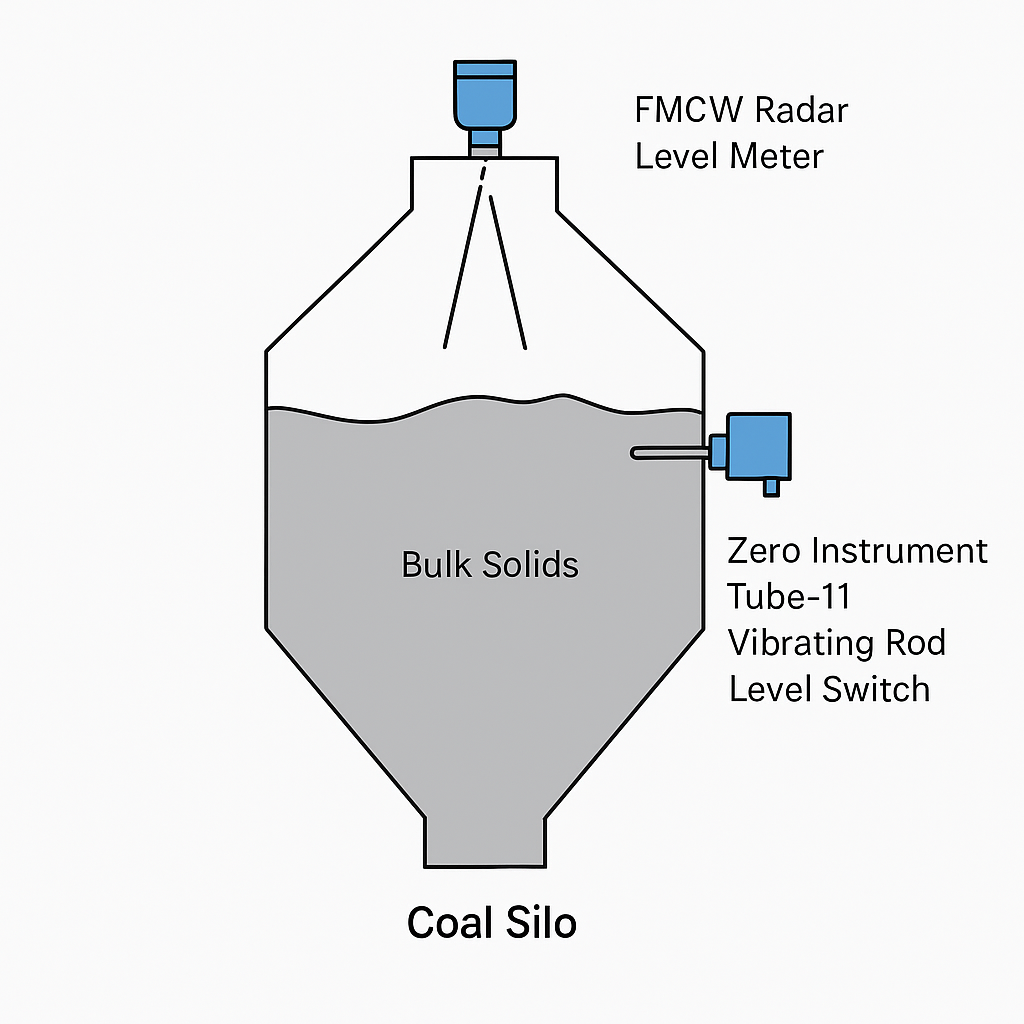

Example Use Case: In a recent dust removal system upgrade, a dual-sensor solution was deployed: a low-frequency radar to penetrate dust layers, followed by a high-frequency radar for accurate level detection.

Benefits:

Improved measurement stability

Fewer process interruptions

Long-term cost savings despite higher initial investment

Recommendation: Use multi-frequency systems for complex measurement environments where neither low nor high-frequency radars alone can perform reliably.

6. Final Selection Tips

Understand your application environment: Evaluate tank structure, medium type, temperature, pressure, and humidity.

Do not rely solely on spec sheets: Real-world performance can differ from advertised precision.

Seek hands-on feedback: Experience from field engineers often proves more useful than brochures.

Trial units before full deployment: If possible, test different frequency units to evaluate actual performance.

Choose reputable suppliers: Strong technical support and after-sales service are essential for minimizing downtime.

7. Frequency Comparison Table

| Frequency Band | Beam Width | Accuracy | Environment Suitability | Typical Applications |

|---|---|---|---|---|

| 6~10 GHz | Wide | Low | Harsh, dusty, steamy | Cement, power plant silos |

| 24~26 GHz | Medium | Medium | General-purpose | Oil tanks, chemical drums |

| 76~81 GHz | Narrow | High | Clean, high-precision | Pharma, fine chemicals |

| Dual Band | Mixed | Optimized | Complex, layered media | Multi-phase storage tanks |

Conclusion

Choosing the right radar level transmitter frequency requires more than just product specifications. It involves understanding your unique process conditions, learning from real-world experiences, and when possible, validating performance on-site. With the right approach, radar technology can significantly enhance measurement reliability and operational efficiency.