Measuring liquid levels in media prone to crystallization presents unique challenges. Crystallization can disrupt measurement accuracy, reliability, and the overall performance of level instruments. To ensure precise monitoring, it’s essential to select an instrument well-suited for handling crystallizing media. This article explores common liquid level measurement instruments and provides guidance on selecting the most suitable technology.

1. Magnetostrictive Level Gauge

Working Principle: Operates based on the magnetostrictive effect. The instrument measures the time interval between the transmitted interrogation pulse and the return pulse, thereby determining the liquid level with high accuracy.

Advantages:

High accuracy and repeatability.

Unaffected by crystallization deposits, providing stable real-time monitoring.

Simple installation and minimal maintenance without the need for additional devices.

Disadvantages:

Relatively higher cost, potentially unsuitable for budget-sensitive projects.

Typical Application: Ideal for scenarios requiring precise measurement and minimal intervention, such as chemical processing plants.

2. Jacketed Magnetic Flap Level Gauge

Working Principle: Based on buoyancy and magnetic coupling. The float moves with the fluid level, magnetically transferring the level indication to a visible display consisting of flipping columns.

Advantages:

Simple and intuitive visual indication.

Easy installation and good visibility over long distances.

Jacketed structure allows heating to prevent crystallization, ensuring accurate measurements.

Disadvantages:

Potential measurement errors if crystallization rate or amount becomes excessive, hindering float movement.

Typical Application: Suitable for storage tanks containing fluids prone to mild crystallization, such as molten salts or high-viscosity oils.

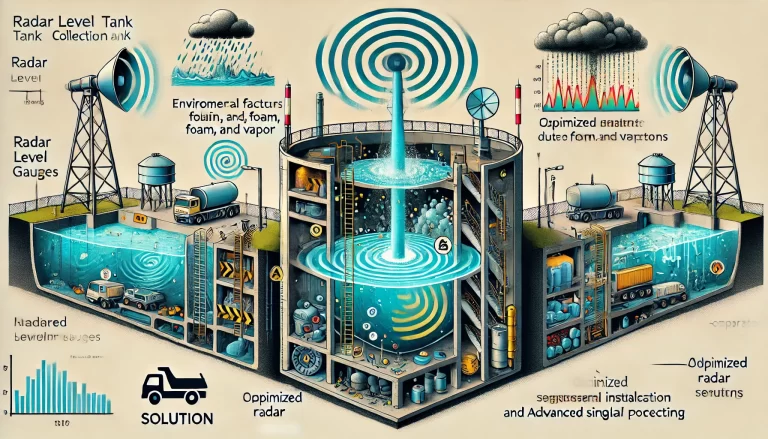

3. Radar Level Gauge

Working Principle: Utilizes the time-of-flight principle, emitting radar waves reflected by the fluid surface to measure level.

Advantages:

Non-contact measurement; unaffected by fluid density, viscosity, or temperature.

Ideal for challenging conditions like high temperature, high pressure, and corrosive environments.

High accuracy and reliability.

Disadvantages:

Crystallization buildup on radar antennas can distort radar waves, reducing measurement accuracy.

Proper antenna selection and installation are critical.

Typical Application: Preferred for highly corrosive and harsh environments, such as chemical reactors containing crystallizing substances.

4. Differential Pressure (DP) Level Gauge (Double-Flange Type)

Working Principle: Measures the liquid level by calculating the pressure difference between two points.

Advantages:

Excellent for crystallizing, viscous, or impurity-containing liquids.

Can measure levels within pressurized, sealed vessels.

Disadvantages:

Regular maintenance and flange cleaning required to prevent crystal accumulation and ensure accuracy.

Installation and calibration can be complex, requiring professional expertise.

Typical Application: Widely used in petrochemical industries and pharmaceutical applications with crystallizing liquids.

5. Float Level Gauge

Working Principle: Operates using buoyancy, where the floating indicator changes position according to fluid level changes.

Advantages:

Simple structure, easy installation, and intuitive readings.

Disadvantages:

Limited accuracy; prone to sticking or drifting when dealing with crystallizing fluids.

Typical Application: Recommended for non-critical monitoring where precision requirements are moderate.

Radar Level Gauge Accuracy in Crystallizing Media

The accuracy of radar level gauges in crystallizing media can vary significantly due to several factors:

Antenna Crystallization: Buildup on the antenna can impair radar wave emission and reception, impacting accuracy. This is especially relevant with substances like sulfur or asphalt, which solidify at elevated temperatures.

False Echoes: Irregular crystallization surfaces can generate false echoes. Incorrect echo interpretation leads to measurement errors.

Vessel and Environmental Factors: Obstacles within vessels, internal reflections, and condensation, especially in cold weather, may further degrade measurement accuracy.

Improving Measurement Accuracy

To maximize radar level gauge performance with crystallizing media:

Select specialized antennas designed to resist crystallization buildup.

Optimize instrument placement to minimize false echo generation.

Schedule regular maintenance and cleaning to maintain accuracy.

Conclusion

Selecting the appropriate liquid level measurement instrument for crystallizing media involves carefully considering the fluid characteristics, required accuracy, maintenance needs, and environmental conditions. Magnetostrictive, jacketed magnetic flap, radar, differential pressure, and float gauges each have their unique strengths and limitations. By understanding these factors and proactively managing crystallization issues, optimal measurement performance can be achieved in even the most challenging applications.