In industries such as chemical processing, water treatment, energy, and food manufacturing, liquid flow measurement is a critical part of process automation. However, liquid media can vary greatly in properties—such as conductivity, viscosity, purity, or corrosiveness—so selecting the right flowmeter requires a comprehensive understanding of both the fluid and the working conditions. This guide provides flowmeter selection recommendations for typical liquid types, along with practical insights and usage tips.

1. Electroplating Wastewater / Chemical Effluent

✅ Recommended Flowmeters:

Electromagnetic Flowmeter

Ultrasonic Flowmeter

📌 Why These Meters:

Electromagnetic flowmeters (magmeters) are ideal for conductive and corrosive liquids. They are non-intrusive, with no moving parts, and can be customized with corrosion-resistant electrodes (e.g., titanium, tantalum, platinum) and PTFE liners. These meters also tolerate solids in suspension, such as slurry or pulp.

Ultrasonic flowmeters are useful for large-diameter pipes and retrofit installations where pipe cutting is not feasible. They are clamp-on, support non-invasive installation, and can be configured with multiple sensors for precise measurements.

⚠️ Considerations:

Magmeters cannot measure non-conductive liquids like oil or deionized water.

Ultrasonic meters (especially transit-time type) are not suitable for strong acid or base solutions.

2. Pure Water / Organic Liquids / Sucrose Solutions

✅ Recommended Flowmeter:

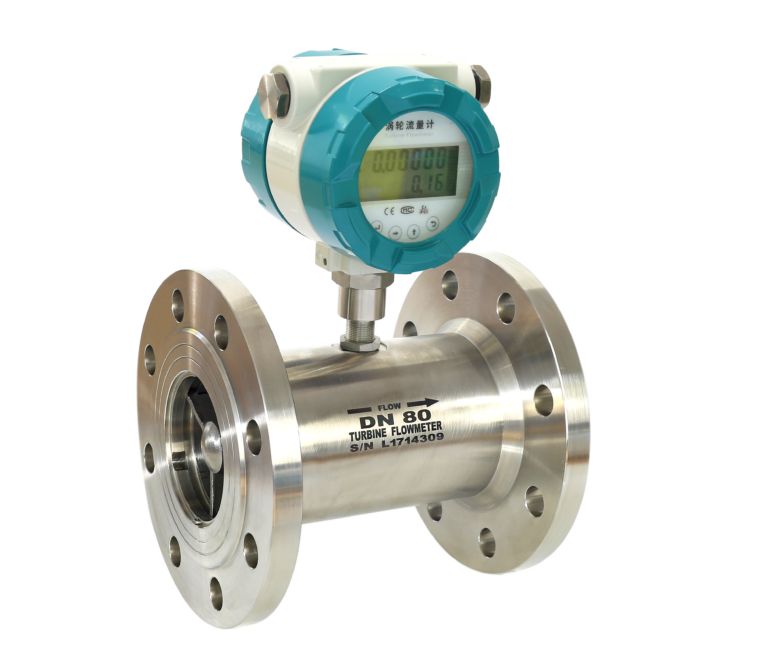

Turbine Flowmeter

📌 Why This Meter:

Turbine flowmeters are highly accurate for low-viscosity, clean liquids. They feature a compact design, large flow capacity, and easy maintenance, making them suitable for measuring pure water, gasoline, diesel, alcohols, and other clean fluids.

⚠️ Considerations:

Not recommended for fluids with high particulates, high viscosity, or corrosiveness.

Rotor blades are subject to wear and must be maintained regularly.

3. High-Viscosity Liquids (Glue, Syrup, Heavy Oil, Resin)

✅ Recommended Flowmeter:

Gear Flowmeter (e.g., Oval or Helical)

📌 Why This Meter:

Gear flowmeters use a positive displacement mechanism to measure small to medium flows of highly viscous liquids. They offer excellent repeatability and accuracy, and the use of corrosion-resistant materials (like PTFE) allows for a wide range of applications in chemicals and food products.

⚠️ Considerations:

Higher initial cost.

Best suited for stable flow applications that require precise volume measurement.

4. Liquids Containing Air Bubbles or Suspended Solids

✅ Recommended Flowmeter:

Doppler Ultrasonic Flowmeter

📌 Why This Meter:

Doppler ultrasonic meters rely on sound waves reflected by bubbles or suspended particles in the fluid. These meters work well in slurries, wastewater, and aerated liquids, especially in wastewater treatment and mining.

⚠️ Considerations:

Measurement accuracy depends on the density and distribution of reflectors (bubbles or solids).

📊 Flowmeter Selection Summary Table

| Liquid Type | Recommended Flowmeter | Key Features | Notes |

|---|---|---|---|

| Electroplating or chemical effluent | Electromagnetic / Ultrasonic | Corrosion-resistant, non-clogging, suitable for slurry | Magmeters need conductivity; ultrasonic not for strong acids/bases |

| Pure water / organic liquids | Turbine Flowmeter | High accuracy for clean, low-viscosity fluids | Not suitable for dirty or corrosive liquids |

| Glue / Syrup / Resin / Heavy oil | Gear Flowmeter | Excellent for high-viscosity fluids, stable performance | Costly, not suitable for pulsating flows |

| Aerated or slurry-type liquids | Doppler Ultrasonic Flowmeter | Non-invasive, suitable for non-uniform mixtures | Accuracy depends on bubble or particle concentration |

🔍 Selection Tips & Conclusion

Conductivity: Essential for using magmeters. Non-conductive liquids require mechanical or ultrasonic meters.

Installation conditions: Clamp-on ultrasonic meters are ideal when pipes can’t be cut or modified.

Viscosity and purity: Use gear or turbine meters depending on cleanliness and flow behavior.

Cost vs. accuracy: Turbine and ultrasonic meters offer a good balance; gear meters are best for precision-critical scenarios.

Always consult with flowmeter manufacturers or instrumentation experts when dealing with complex fluids or demanding environments. Proper selection ensures measurement accuracy, system reliability, and long-term cost savings.