Introduction

When designing a weighing or force measurement system, selecting the right load cell is only part of the process.

Choosing the correct mounting kit is equally important to ensure accurate, stable, and reliable operation.

A poorly chosen or installed mounting system can lead to significant errors, mechanical failures, or even permanent sensor damage.

This article explains what a load cell mounting kit is, why it matters, and how to choose the right one for your application.

1. What Is a Load Cell Mounting Kit?

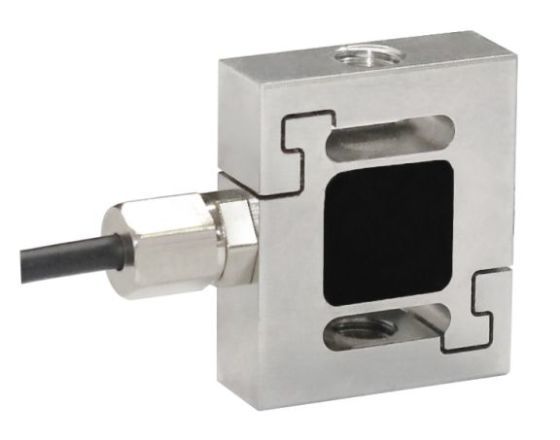

A mounting kit includes the mechanical hardware needed to securely install a load cell while allowing it to perform accurately under real-world forces.

Mounting kits typically consist of:

Load introduction plates or fixtures

Anti-lift-off, anti-rotation, or sway control components

Rocker pins, spherical washers, or elastomeric elements

Alignment tools for minimizing side loads

They help ensure the force is properly aligned along the load cell’s primary axis while protecting against external disturbances like vibration, thermal expansion, or mechanical shock.

2. Why Is the Mounting Kit Important?

Without proper mounting:

Side loads can introduce significant errors

Torsion and bending moments may cause signal drift or sensor damage

Vibration and uneven settling may lead to unstable readings

Installation may violate sensor calibration assumptions

A well-designed mounting kit preserves the calibrated accuracy of the load cell in real-world conditions.

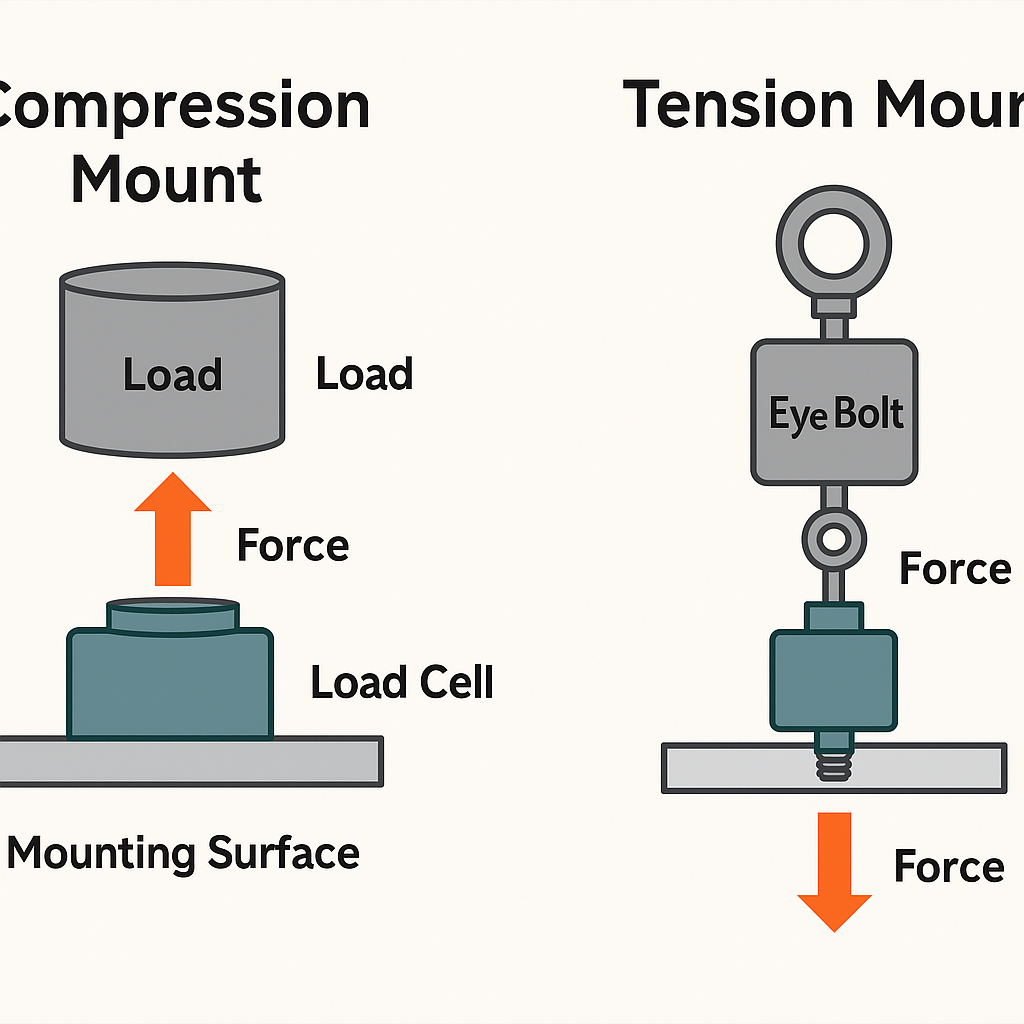

3. Types of Load Cell Mounting Kits

| Kit Type | Typical Application |

|---|---|

| Compression Mount Kits | Tanks, hoppers, silos weighing |

| Tension Mount Kits | Suspended weighing, crane scales |

| Universal Mount Kits | Systems that experience both tension and compression |

| Anti-vibration Mounts | Dynamic or vibrating environments (e.g., mixers) |

| Self-aligning Bearing Kits | Systems with slight structural movement |

4. Key Selection Criteria

✅ Load Direction

Compression Only → Use compression-specific kits

Tension Only → Use tension kits with clevis or eye bolt fittings

Bidirectional → Consider universal or hybrid kits

✅ Capacity Range

The mounting kit must match or exceed the load cell’s full-scale rated capacity.

✅ Environmental Conditions

Outdoor installations may need stainless steel hardware and IP-rated sealing

Dynamic environments benefit from shock-absorbing or elastomeric bases

✅ Movement Constraints

Hopper systems or high-vibration machinery should use kits with:

Lift-off protection

Sway restraints

Thermal expansion accommodation

✅ Installation Space

Some kits require additional vertical or lateral clearance.

Check dimensions to ensure proper integration into your machine or structure.

5. Common Mistakes to Avoid

Using rigid bolting without allowing slight movement (leads to binding and side loads)

Mismatching mount types to the load direction

Underestimating dynamic loads and vibration

Ignoring thermal expansion in outdoor or high-temperature sites

Improper torque or preload settings during installation

6. Pro Tips for Installation

Always align the force path with the load cell axis

Hand-tighten and use specified torque values to avoid preloading errors

Use dummy weights or simulation during mechanical integration checks

Review the load cell and mounting kit as a complete mechanical system—not as isolated components

Conclusion

Selecting the right load cell mounting kit is crucial for maintaining measurement accuracy, protecting your sensors, and ensuring system longevity.

By carefully considering your load type, environment, and application dynamics, you can design a weighing or force measurement system that is both robust and highly accurate.

A few extra minutes spent on choosing the correct mounting kit can save you hours of troubleshooting and thousands in maintenance costs later.