When dealing with crystallizing media, selecting the right type of level transmitter is essential to ensure accuracy, reliability, and durability. Crystallization can obstruct or interfere with sensors, causing inaccurate readings or equipment failure. In this article, we will explore the key selection principles, suitable types of level transmitters, and practical measures for ensuring smooth operation in challenging conditions.

I. Key Selection Principles

Anti-Crystallization Design:

- Crystals can form on sensors, causing blockages or inaccurate readings. Non-contact level transmitters, such as radar or ultrasonic sensors, are preferred to avoid direct interaction with crystallizing media.

Corrosion Resistance:

- If the crystallizing media is chemically aggressive (e.g., acids or salts), the level transmitter should be made of corrosion-resistant materials such as 316L stainless steel, PTFE (Teflon), or Hastelloy.

Ease of Cleaning and Maintenance:

- Since crystallization is often inevitable, it is crucial to choose a design that facilitates periodic cleaning or integrates self-cleaning features like flushing ports.

Continuous or Discrete Measurement:

- Depending on whether continuous monitoring or simple point-level detection is required, the appropriate type of transmitter or switch should be selected.

Installation Environment:

- Assess installation conditions such as pressure, temperature, and accessibility. Remote, hard-to-reach installations may benefit from non-contact or low-maintenance options.

II. Types of Suitable Level Transmitters for Crystallizing Media

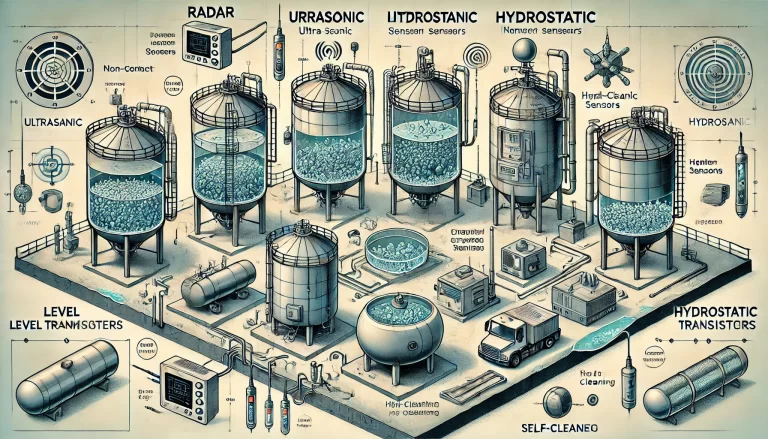

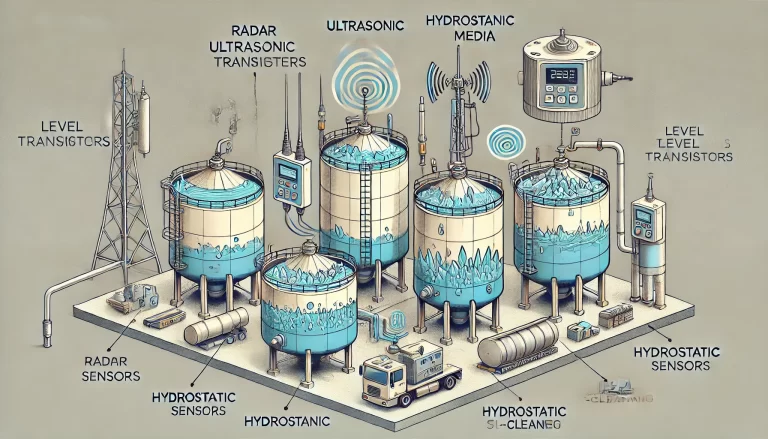

1. Radar Level Transmitters (Recommended)

How it Works: Radar level sensors use electromagnetic waves to measure the distance between the transmitter and the liquid surface.

Advantages:

- Non-contact measurement: Prevents direct exposure to crystallization.

- High accuracy and reliability: Not affected by vapors, foam, or process conditions.

- Pressure and temperature tolerance: Suitable for harsh environments such as chemical plants and crystallizing tanks.

Best Use Case: Suitable for continuous level measurement in closed tanks or open containers with high crystallization potential.

2. Ultrasonic Level Transmitters

How it Works: Ultrasonic transmitters emit sound waves that bounce back from the surface of the media to determine the level.

Advantages:

- Non-contact design: Helps avoid blockage or buildup on the sensor.

- Lower cost: More economical than radar technology for less demanding applications.

Limitations: Crystals forming on the sensor surface or in the vapor space may interfere with ultrasonic signals.

Best Use Case: Open tanks or vessels without excessive vapor, used in water treatment or food processing where crystallization is moderate.

3. Hydrostatic (Pressure) Level Transmitters

How it Works: Measures the hydrostatic pressure exerted by the liquid column to determine the level.

Advantages:

- Simple and robust: Can be used in large tanks with moderate crystallization.

- Cost-effective: Suitable for continuous monitoring in simple applications.

Limitations: Crystallization on the pressure port or diaphragm can cause blockages or incorrect readings.

Best Use Case: Large storage tanks where periodic maintenance is feasible, such as brine or slurry applications.

4. Float-Based Level Switches

How it Works: A float rises or falls with the liquid level, activating a switch at a preset point.

Advantages:

- Simple design: Easy to install and maintain.

- Reliable point-level detection: Useful for simple on/off control systems.

Limitations: Susceptible to clogging and malfunction due to crystallization around the float mechanism.

Best Use Case: Low-crystallization media or when used in conjunction with periodic cleaning.

5. Magnetic Level Gauges (Magnetic Float)

How it Works: A magnetic float moves with the liquid level, rotating indicator flaps to display the level.

Advantages:

- Visual indication: Easy-to-read display with no external power required.

- Sealed design: Suitable for liquids with minimal crystallization risk.

Limitations: May need frequent cleaning to prevent crystallization buildup on the float.

Best Use Case: Processes requiring visual inspection in non-critical applications.

III. Special Considerations and Enhancements for Crystallizing Media

Heating or Insulation:

- To prevent crystallization, install heating jackets or insulation around the sensor, transmitter, or vessel walls. Electric trace heating can also be applied to maintain process temperature.

Flushing and Cleaning Systems:

- Install flushing ports to allow the periodic cleaning of sensors and tubes without dismantling equipment. Automatic flushing systems can reduce maintenance efforts.

Anti-Adhesive Coatings:

- Apply coatings such as Teflon (PTFE) to sensor surfaces to reduce the risk of crystal adhesion. These coatings also enhance corrosion resistance.

Redundant Measurement Systems:

- Use multiple level measurement technologies (e.g., radar with float switches) to ensure reliable operation and avoid downtime due to sensor failures.

IV. Recommendations Based on Use Cases

Chemical Plants:

Radar level transmitters are ideal for tanks with crystallizing chemicals due to their non-contact measurement and resistance to extreme conditions.Water Treatment Facilities:

Ultrasonic level transmitters are suitable for open tanks with low to moderate crystallization, such as saltwater reservoirs.Large Storage Tanks:

Hydrostatic pressure transmitters can be used with brines or slurries, provided that regular maintenance is performed to prevent blockages.Simple On/Off Control Systems:

Float-based level switches or magnetic level gauges can be used for non-critical processes with limited crystallization issues.

V. Conclusion

Selecting the right level transmitter for crystallizing media requires careful evaluation of the process conditions and the characteristics of the media. Radar level transmitters are often the preferred choice due to their non-contact design and high reliability in challenging environments. However, other technologies such as ultrasonic, hydrostatic, or float-based level transmitters may also be suitable, depending on the specific application.

To enhance performance and reduce maintenance, insulation, flushing systems, and anti-adhesive coatings should be incorporated. With the correct level measurement system in place, the challenges posed by crystallizing media can be effectively managed, ensuring smooth operation and minimal downtime.