Introduction

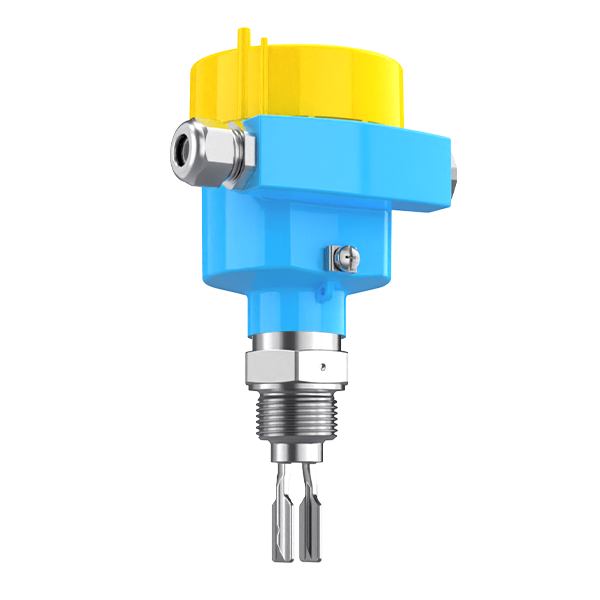

When testing and verifying a tuning fork level switch, many users habitually grip the fork with their hands to check whether the device responds. However, this testing method is not suitable for high-end tuning fork level switches and can lead to incorrect judgments or even potential device damage. One such example is the Zero Instrument Ring-11 Tuning Fork Level Switch.

While some low-end tuning fork level switches may still respond when touched by hand due to their simplistic detection mechanism, Ring-11 employs advanced technology that prevents such manual activation. This article explains why the conventional hand-held test does not work for Ring-11, outlines the correct testing procedure, and provides insights to help users ensure the device’s reliability and longevity.

Why Hand-Held Testing Does Not Work

1. Different Detection Principles in Low-End vs. High-End Switches

Many standard tuning fork level switches operate based on a basic mechanical vibration detection principle. These low-end models have relatively low sensitivity and can easily be triggered by grasping the tuning fork, causing the device to falsely detect the presence of liquid. However, these designs are highly susceptible to environmental interference, such as vibrations and temperature fluctuations, leading to incorrect readings.

In contrast, the Ring-11 Tuning Fork Level Switch is specifically designed for liquid media detection. Unlike conventional switches, Ring-11 will not be triggered even if wrapped in non-liquid materials such as rubber clay. Only when the fork is fully immersed in liquid will the vibration frequency change significantly, triggering the alarm signal and ensuring accurate level detection.

2. Key Features of the Ring-11 Tuning Fork Level Switch

✅ High-Precision Frequency Detection Algorithm – Unlike cheap alternatives that rely on mechanical vibrations, Ring-11 determines liquid presence based on vibration frequency changes. The frequency shift caused by grasping the fork with a hand is insufficient to trigger the switch.

✅ High-Temperature Resistance (Up to 280°C) – Compared to the industry standard of 220°C, Ring-11 is designed to operate reliably in extreme temperatures, making it ideal for high-temperature industrial applications.

✅ Protection Against Manual Damage – While some low-end products allow hand-held testing, Ring-11’s high-sensitivity detection mechanism makes it more susceptible to physical damage if excessive force is applied to the fork. This could result in permanent loss of accuracy.

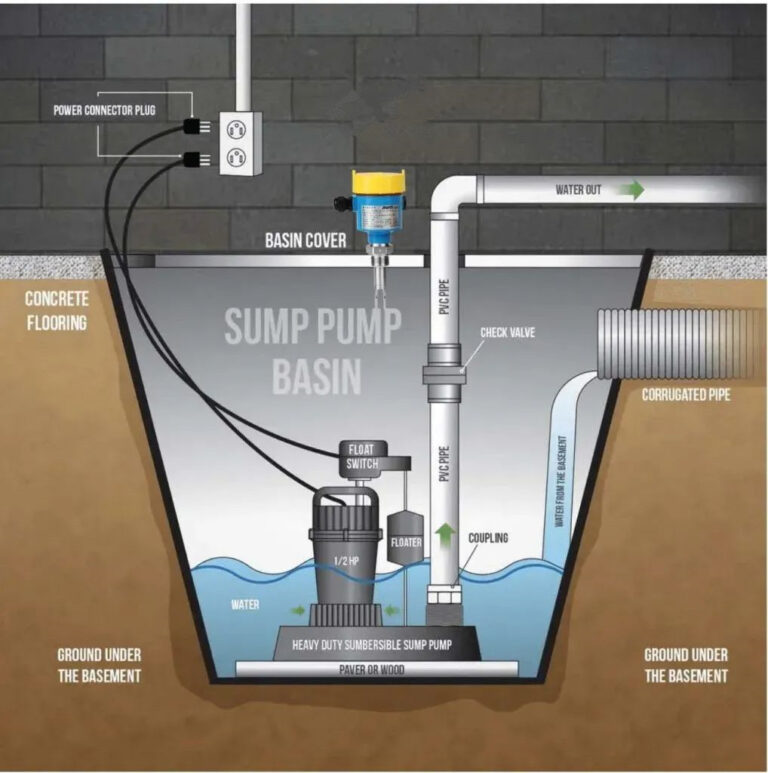

Correct Testing Method: Liquid Immersion Test

Since Ring-11 cannot be tested manually by hand, the correct way to verify its functionality is through a liquid immersion test. Below are the recommended steps to ensure accurate testing:

Step 1: Prepare the Proper Test Medium

Select an appropriate liquid based on the actual application, such as water, oil, or other industrial liquids.

Ensure the liquid volume is sufficient to fully submerge the tuning fork probe.

Step 2: Power On and Check Initial Status

Connect the power supply to the tuning fork level switch.

Verify that Ring-11 is in its normal standby mode (typically indicating a ‘no liquid’ state).

Observe the initial signal output; the switch should not be activated at this stage.

Step 3: Immerse the Tuning Fork in Liquid

Carefully lower the tuning fork into the liquid, ensuring full submersion.

Avoid sudden or aggressive movements that may introduce bubbles, as air pockets can affect accurate detection.

Make sure the fork is positioned properly to prevent tilting, which might impact results.

Step 4: Verify Signal Changes

When the tuning fork is fully immersed in the liquid, the frequency shift should trigger the switch.

Observe LED indicator lights, relay operations, or signal outputs to confirm activation.

Remove the tuning fork from the liquid and check whether the device correctly resets to the ‘no liquid’ state.

Comparison: Ring-11 vs. Low-End Tuning Fork Level Switches

| Feature | Ring-11 Tuning Fork Level Switch | Low-End Tuning Fork Level Switch |

|---|---|---|

| Detection Mechanism | Advanced frequency analysis | Basic mechanical vibration detection |

| Resistance to Environmental Factors | High immunity to interference | Prone to false triggers due to vibration & temperature changes |

| Temperature Tolerance | Up to 280°C | Typically up to 220°C |

| Manual Test Feasibility | Cannot be triggered by hand | Can be falsely activated by grasping |

| Durability & Reliability | High-precision, long lifespan | Prone to errors and wear over time |

Summary: Avoiding Misconceptions & Ensuring Accurate Testing

✅ Incorrect Testing Method: Hand-Held Testing (Works for low-end products but is ineffective for Ring-11)

❌ Light gripping does not alter the frequency. ❌ Excessive force can damage the tuning fork. ❌ Cannot accurately simulate liquid contact conditions.

✅ Correct Testing Method: Liquid Immersion Test

✔ Use water or another suitable liquid for testing.

✔ Ensure the tuning fork is fully submerged and monitor alarm signals.

✔ Confirm that the switch resets when the fork is removed from the liquid.

Unlike generic tuning fork level switches, Zero Instrument Ring-11 employs an advanced frequency detection system, offering superior accuracy, reliability, and resistance to external interferences. By following the proper testing procedures, users can maximize the performance of their device, prevent misinterpretations, and avoid operational risks.

Choosing the correct testing method ensures that your equipment meets operational requirements and eliminates the possibility of incorrect judgments or malfunctions.