Electromagnetic flow meters are among the most widely used instruments in industrial process measurement—and also among those most prone to installation-related issues. Their output signal is extremely weak and easily affected by electromagnetic interference, so proper grounding and installation are crucial to achieving accurate and stable measurement.

This guide explains why grounding is essential, how to ground a magnetic flow meter correctly, the differences between excitation methods, key installation requirements, and commissioning steps.

1. Why Is Grounding Important for Electromagnetic Flow Meters?

An electromagnetic flow meter generates only 2.5–8 mV at full scale, and just a few microvolts at low flow rates. Even slight external interference—ground potential differences, electrical noise, static electricity—can significantly impact measurement accuracy.

To ensure stable and reliable operation, grounding must be handled correctly.

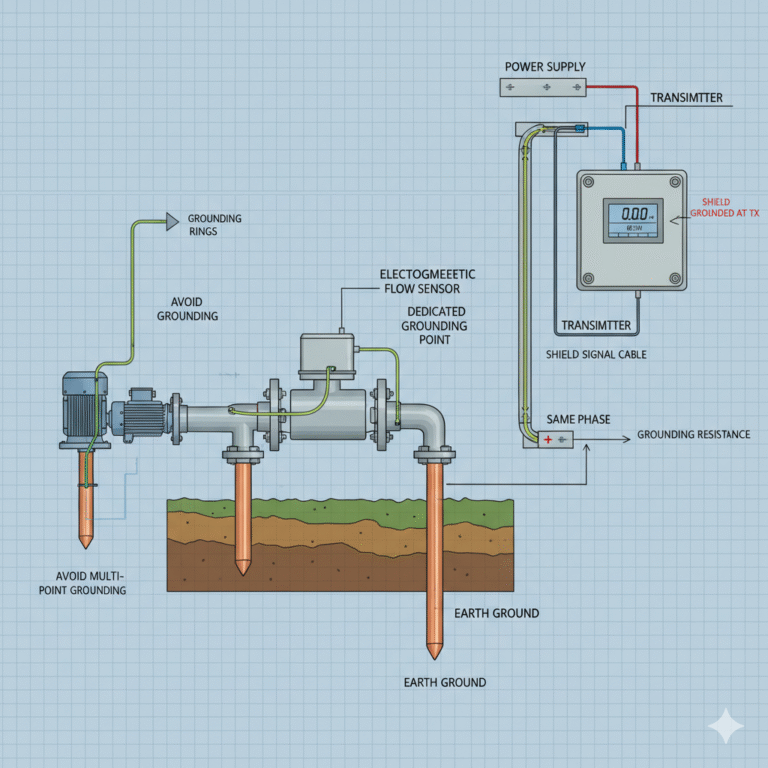

Key Grounding Principles

Ground everything that relates to the measurement, including the sensor’s measuring tube, housing, shielding cable, transmitter, and secondary instruments.

The sensor and transmitter must have a dedicated grounding point, independent from motors, pumps, or process pipelines.

The grounding resistance should be <10 Ω.

Avoid multi-point grounding between field and control room.

The shield layer should be grounded at the control room side only.

Install grounding rings when necessary:

If installed on plastic pipes or pipes with insulating lining, both ends of the sensor must have grounding rings (or grounding electrodes) to ensure the fluid inside has zero potential.

If installed on bare metal pipes without internal coating, the sensor grounding terminal is sufficient.

Proper grounding directly determines whether the flow meter can maintain accuracy and stability.

2. Magnetic Field Excitation Methods: DC, AC, and Square-Wave

A magnetic flow meter measures flow based on the voltage induced as conductive fluid cuts through a magnetic field. Therefore, the excitation method that generates this magnetic field is critical.

There are three main excitation methods, each with its characteristics:

① DC Excitation

Uses direct current or permanent magnets.

Advantages:

Minimal AC electromagnetic interference.

Negligible inductive effects inside the liquid.

Disadvantages:

Causes electrode polarization (ions accumulate on electrodes), increasing internal resistance and distorting measurement.

Permanent magnets become large and heavy for bigger pipe sizes.

② AC Excitation (50 Hz)

Uses standard AC power for the magnetic field.

Advantages:

Eliminates electrode polarization.

AC signals are easier to amplify.

Disadvantages:

Produces 90° phase-shift interference (quadrature noise).

Interference can exceed signal level, causing unstable readings.

③ Constant Current Square-Wave Excitation (Most Advanced)

Uses alternating positive/negative square-wave current pulses.

Advantages:

Avoids electrode polarization (better than DC).

Eliminates AC-induced interference voltage.

Maintains stable sensor constants for easy interchangeability.

Less affected by voltage or frequency fluctuations.

This is considered the optimal excitation method in modern magnetic flow meters.

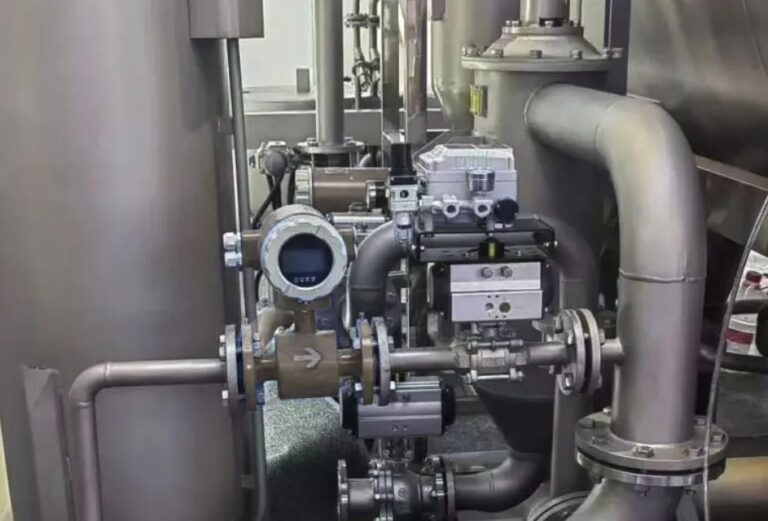

3. Installation Requirements for Electromagnetic Flow Meters

Correct installation ensures stable flow profile, full pipe conditions, and minimal interference.

① Installation Orientation

Vertical installation (fluid flowing bottom → top) is recommended, especially for slurry or solids.

Horizontal installation is acceptable but should avoid placing electrodes on top/bottom where bubbles or sediment collect.

② Ensure Full Pipe Conditions

The meter must always remain full of liquid. Avoid:

High points in the pipeline

Downstream of pumps where cavitation occurs

Partially filled pipes

③ Grounding and Cabling Requirements

Because the signal is extremely weak:

Sensor body, shielding cable, and conductive pipeline must be properly grounded.

Use the manufacturer-specified shielded signal cable.

Keep signal cable and excitation cable in separate conduits.

Avoid routing near power cables.

Locate the transmitter close to the sensor when possible.

④ Straight Pipe Requirements

At least 5D upstream,

3D downstream,

If near valves or reducers, increase upstream straight length to 10D.

⑤ Power Supply Requirements

Sensor and transmitter must be powered from the same phase.

Otherwise, phase shift may cause unstable measurement.

4. Key Features and Limitations of Electromagnetic Flow Meters

Main Advantages

No obstruction in the measuring tube → no pressure loss.

Linearity is excellent, suitable from DN2.5 mm to DN3000 mm.

Various lining and electrode materials allow measurement of corrosive fluids.

High accuracy: ±0.2% – ±0.5%.

Wide turndown ratio: 1:20.

Short upstream requirements compared to orifice plates or turbines.

Limitations

Only suitable for conductive liquids (≥ 5 μS/cm).

Not suitable for oil, gas, steam, or non-conductive fluids.

Typical temperature limit: ≤180°C.

Typical pressure limit: ≤4 MPa.

5. Commissioning Procedure for Electromagnetic Flow Meters

Follow these steps to ensure accurate start-up:

Open valves and fill the sensor with liquid.

Check and eliminate leaks (especially flange connections).

Remove air pockets from the pipeline.

Power on sensor and transmitter to allow warm-up.

Close downstream valve to establish static full-pipe condition.

Perform zero-point calibration.

Reopen valves to achieve full flow and verify stable and correct output.

Proper commissioning ensures consistent long-term accuracy.