Preventing water ingress in explosion-proof electrical equipment is essential to ensure safety and operational reliability. Below is a detailed guide to implementing effective measures for this purpose.

1. Choose the Right Protection Level

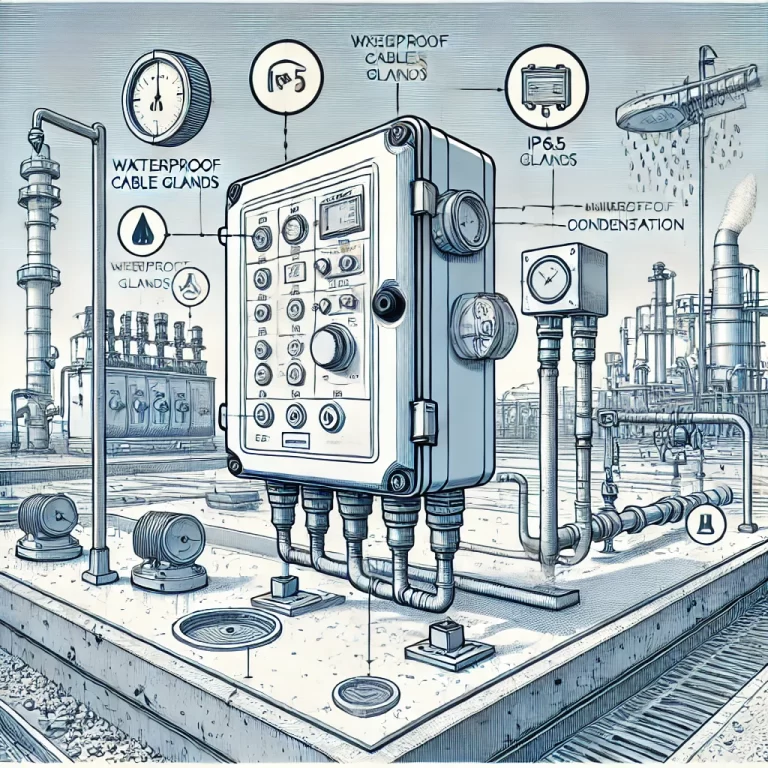

- IP Protection Rating: Select equipment with an Ingress Protection (IP) rating appropriate for the environment. For wet or damp locations, devices with IP65 or higher are recommended. This ensures they are dust-tight and protected against water jets or even immersion.

- Waterproof Cable Glands: Use high-quality waterproof cable glands at cable entry points to enhance sealing performance.

2. Ensure Proper Installation and Sealing

- Inspect Sealing Components: Before installation, inspect all sealing components, such as gaskets, O-rings, or sealing strips, for signs of wear, deformation, or damage.

- Tighten Bolts and Covers: During installation, ensure bolts and covers are securely fastened. Uneven tightening can compromise the sealing, allowing water to seep in.

- Install at an Angle: Avoid flat installations where water can pool. Instead, position equipment at a slight angle to facilitate runoff.

3. Environmental Management

- Avoid Water-Prone Areas: Install equipment away from direct water exposure, such as under sprinklers or in areas prone to flooding.

- Use Protective Covers: In outdoor or exposed areas, provide additional protection such as rain shields, canopies, or weather-resistant enclosures.

- Implement Drainage Systems: Ensure proper drainage around the equipment’s installation site to prevent water accumulation and reduce the risk of seepage.

4. Incorporate Waterproof and Breathing Design

- Install Breather Valves: Use specialized waterproof breather valves to equalize internal and external pressure, reducing the risk of water being drawn in due to pressure differences.

- Anti-Condensation Measures: In high-humidity environments, consider installing dehumidifiers or anti-condensation heaters to manage internal moisture levels and prevent water condensation inside the equipment.

5. Conduct Regular Inspection and Maintenance

- Inspect Seals and Joints: Regularly check the condition of seals, gaskets, and cable glands for wear and tear. Replace any compromised components promptly.

- Clean Equipment Surfaces: Ensure that the surfaces are free from dirt, grease, or debris that might obstruct drainage or increase water retention.

- Internal Inspections: Periodically open the equipment to check for any signs of moisture, condensation, or corrosion inside the enclosure.

6. Apply Protective Coatings

- Waterproof Coatings: Enhance the water resistance of the enclosure by applying high-quality waterproof and anti-corrosion coatings to the exterior. This adds an extra layer of protection, especially in highly corrosive or wet environments.

7. Utilize High-Quality Components

- Certified Materials: Use materials that are specifically designed for harsh or wet environments, such as stainless steel or specialized polymer enclosures.

- Explosion-Proof Standards: Ensure all components meet relevant explosion-proof standards to maintain integrity under all environmental conditions.

8. Prepare for Extreme Conditions

- Weatherproofing Solutions: If the equipment operates in extreme weather, consider investing in advanced weatherproofing measures, including thermal insulation and UV-resistant coatings.

- Emergency Protocols: Have protocols in place to address unexpected water ingress, such as immediate shutdowns and drying mechanisms.

Conclusion

Preventing water ingress in explosion-proof electrical equipment is not just about selecting the right hardware—it involves a holistic approach to installation, environmental management, regular maintenance, and proactive upgrades. By implementing the measures above, you can significantly enhance the durability and reliability of the equipment, ensuring safety and compliance in demanding operational environments.