Positive migration moves in the positive direction, negative migration moves in the negative direction, and the distance moved is the migration amount.

Therefore, the essence of positive and negative migration is to change the upper and lower limits of the range by adjusting the transmitter, while the size of the range remains unchanged.

It can also be remembered like this: when the input pressure is zero (0%), the output current signal is also zero (0%), which means no migration; when the input pressure is zero (0%), the output current signal is positive and greater than the working zero point, which means negative migration; when the input pressure is zero (0%), the output current signal is negative and less than the working zero point, which means positive migration.

No Migration

This is a transmitter used to measure differential pressure, used to measure the liquid level of the tank. It is connected to the positive pressure side and the negative pressure side is connected to the other end. In this case, there is no need to migrate. This double flange liquid level transmitter also does not need to be migrated.

In this case, migration is required. When the pressure port is higher than the transmitter, the transmitter needs to be positively migrated. In actual situations, the upper part is the pressure port, and the lower part is a cartridge pressure measurement. The capillary part is filled with silicone oil. When there is no pressure, the silicone oil in the capillary also has pressure. At this time, the transmitter needs to be positively migrated.

Positive Migration

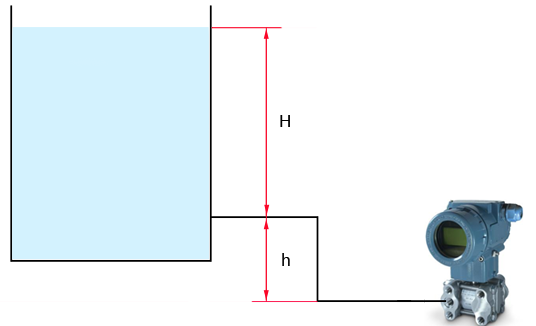

A common phenomenon in measurements, as shown in the figure, is a form of migration.

According to observation, the container is an open container, h is the height difference between the installation position of the transmitter and the measured liquid level, and then the function relationship related to the pressure difference ΔP can be obtained ΔP=ρgH+ρgh.

Assuming that the output pressure of the differential pressure transmitter is greater than 4mA, in addition to ensuring that a part of the static pressure remains in the positive pressure chamber of the differential pressure transmitter, it is also necessary to assume that the installation position of the differential pressure transmitter and the measured liquid level are maintained on the same horizontal plane, that is, H is 0; then when H is taken as the maximum value, the equation ΔP=ρgH+ρgh can be obtained.

At this time, the output pressure of the transmitter has exceeded the limit value of 20mA, which shows that the static pressure generated by ρgh is a redundant part and must be eliminated, and then a type of migration is obtained, which is called positive migration.

In the following situation, the transmitter needs to be negatively migrated, because the installation position of the transmitter is higher than the pressure port.

In the absence of pressure, the silicone oil itself produces a reverse pressure on the transmitter, that is, negative pressure, so the transmitter needs to be negatively migrated. In this way, the pressure of the pipeline can be accurately measured. No matter where the double flange level transmitter is installed, it must be negatively migrated.

Whether it is installed above the upper flange or between the two flanges, it is negatively migrated. In the example figure, the level meter is installed between the two flanges and needs to be negatively migrated.

Negative Migration

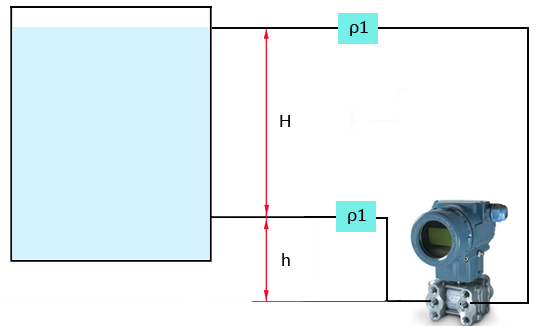

As shown in the figure, it is the principle diagram of negative migration. If the liquid or gas in the sealed container is injected into the pressure chamber of the differential pressure transmitter during operation, the measuring pipeline will suffer a great degree of damage, or even serious corrosion, in order to prevent the liquid or gas in the sealed container from flowing.

Therefore, the isolation tank is installed between the positive and negative pressure chambers of the differential pressure transmitter and the pressure point, and an isolation liquid with a density of ρ1 is injected.

If we assume that H is 0 and the maximum value respectively, we can get two different values of the pressure difference ΔP, which just shows that when H is 0, 4mA is the limit value of the differential pressure transmitter, but when H is the maximum value, the actual density of the isolation liquid is far beyond the expected value.

Therefore, when it is at the highest position, the pressure in the negative pressure chamber is greater than that in the positive pressure chamber, which causes the actual liquid level instrument output pressure value to be inconsistent with the theoretical calculation, which seriously affects the balance between the liquid level and the transmitter output pressure.

After analysis, in order to maintain the relationship between the actual liquid level and the instrument, the most fundamental measure is to remove the static pressure from the negative pressure chamber pressure line.

During this period, the negative migration technology of the differential pressure transmitter needs to be used, and the migration amount can be regarded as ρ1gh.

Both double-balanced and single-balanced level gauges require negative migration, because the pressure received by the negative pressure side of the transmitter is always greater than the positive pressure measurement in the case of empty liquid level.

Therefore, in order to accurately measure the liquid level of the tank, the transmitter needs to be negatively migrated.