1. Introduction

Remote control refers to the ability to monitor and manage the behavior and outcomes of system components located in distant or distributed areas. Programmable Logic Controllers (PLCs), known for their versatile communication interfaces and robust networking capabilities, are well-suited for remote control applications. With continuous advancements in PLC networking modules and architectures, implementing remote control is not only possible but increasingly efficient and scalable.

2. Common Methods of Implementing Remote Control with PLCs

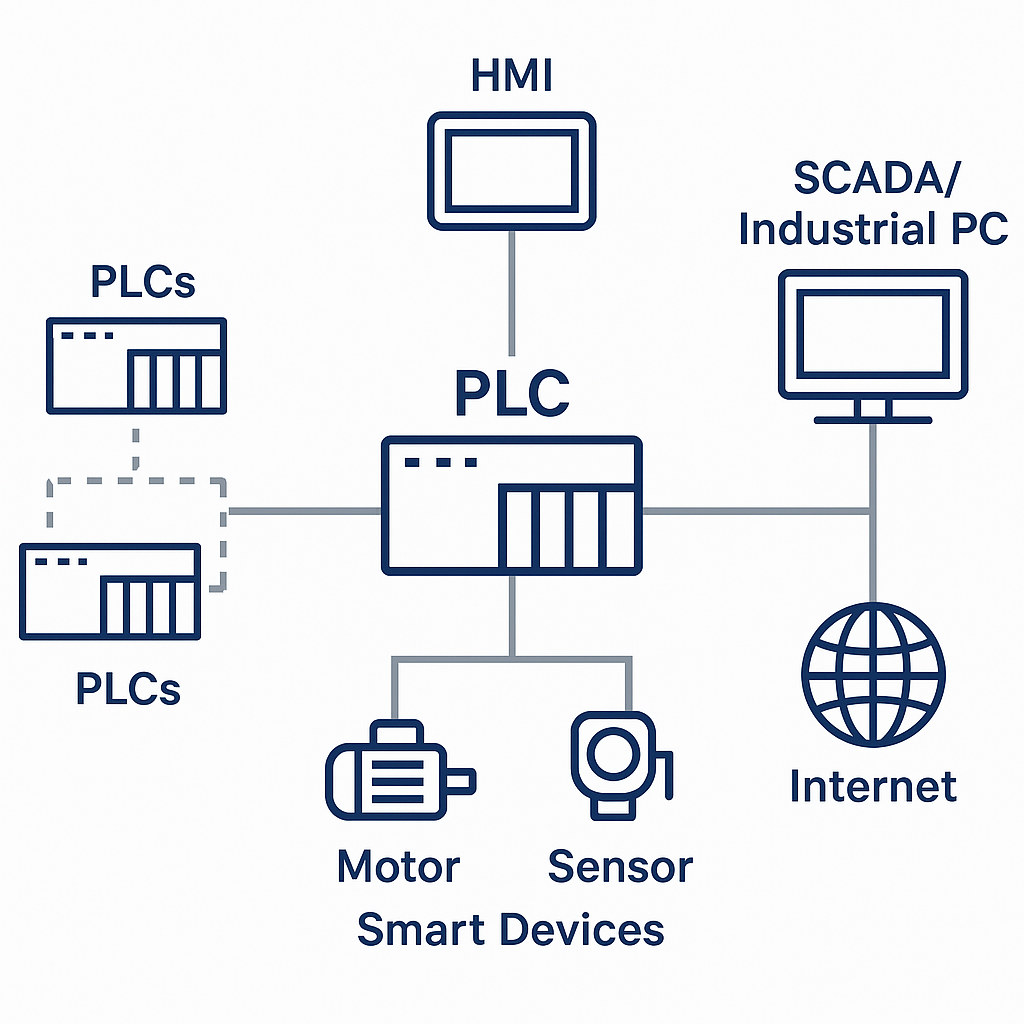

2.1 PLC-to-PLC Communication Networks

PLCs can form control networks by connecting with each other directly. These networks allow for:

Real-time communication

Data exchange

Mutual coordination of control tasks

A single PLC network can support dozens or even hundreds of nodes. Furthermore, multiple PLC networks can be interconnected, effectively removing limits on system scalability.

2.2 Device-Level Networks

PLCs can also be connected to smart field devices such as:

Intelligent sensors

Variable frequency drives (VFDs)

Smart actuators

This forms a device-level network, enabling remote data exchange and operational coordination. Such networks can cover distances from tens to hundreds of meters or more, allowing comprehensive monitoring and decentralized control across large industrial facilities.

2.3 Communication with Human-Machine Interfaces (HMIs)

PLCs can communicate with programmable terminals or Human-Machine Interfaces (HMIs). Operators can:

Monitor system status through real-time display

Send control commands to PLCs

Modify parameter settings easily

This greatly improves user interaction and operational flexibility.

2.4 Integration with SCADA and Industrial PCs

When connected to industrial computers, PLCs become part of larger SCADA (Supervisory Control and Data Acquisition) systems. These systems benefit from the powerful data processing and visualization capabilities of PCs, enabling:

Comprehensive process monitoring

Historical data logging

Alarm handling and trend analysis

Remote PLC programming and diagnostics

2.5 Ethernet and Internet Integration

Modern PLCs often support Ethernet modules, allowing them to connect to:

Local area networks (LANs)

Wide area networks (WANs)

The Internet

In advanced applications, PLCs can be assigned IP addresses, host web pages, and even be accessed through cloud-based platforms. Such setups give rise to concepts like the “Transparent Factory”, where authorized personnel can monitor and control industrial processes from anywhere in the world via a secure internet connection.

3. Advantages of Remote Control in PLC Applications

Remote control significantly expands the operational capabilities and geographic reach of PLC-based systems. Key benefits include:

Enhanced Monitoring: Real-time visibility of field conditions from a central location.

Reduced Wiring and Maintenance: Less physical wiring is required, simplifying installation and reducing system downtime.

Improved Resource Utilization: For example, the city of Weihai in China implemented PLC-based remote management of water resources, reducing waste and ensuring water availability for residents.

Strategic Advantages: In critical infrastructure or defense applications, remote control offers clear tactical superiority, enabling one side to observe and act while remaining unseen and untouchable.

4. Remote Control as a Step Toward Smart Automation

Remote control represents a critical step in the evolution of industrial automation:

Automation ensures systems operate without manual intervention.

Informationization enables integration with digital data systems.

Remoteization extends operational control beyond physical boundaries.

Together, these pave the way for intelligent automation—systems that not only act autonomously but also adapt to changing conditions based on diagnostics, learning, and optimization algorithms.

PLCs, with built-in self-diagnostic functions and flexible programming logic, are well-positioned to serve as the core controllers in this progression toward smarter, more resilient industrial systems.

5. Conclusion

While remote control can be implemented using various industrial technologies, PLCs remain at the heart of modern control systems due to their flexibility, reliability, and integration potential. As industries continue to evolve toward large-scale, fully connected, and intelligent operations, the role of remote PLC control will only grow in importance.

Future trends will focus on:

Enhanced cybersecurity

Edge computing with PLCs

Cloud-based PLC management

AI-assisted adaptive control

Investing in PLC-based remote control is not just about extending reach—it’s about building a smarter, safer, and more efficient industrial future.