1. Introduction

In process control, the Proportional–Integral–Derivative (PID) controller is one of the most widely used strategies.

However, when the setpoint (SP) undergoes a sudden step change, the standard PID often causes controller output overshoot, valve oscillations, and mechanical stress.

To address this issue, an improved structure known as Proportional–Derivative First (PD–PI) Control has been developed.

This document analyzes the working principle, advantages, and typical application scenarios of PD–PI control, and compares it with the standard PID approach.

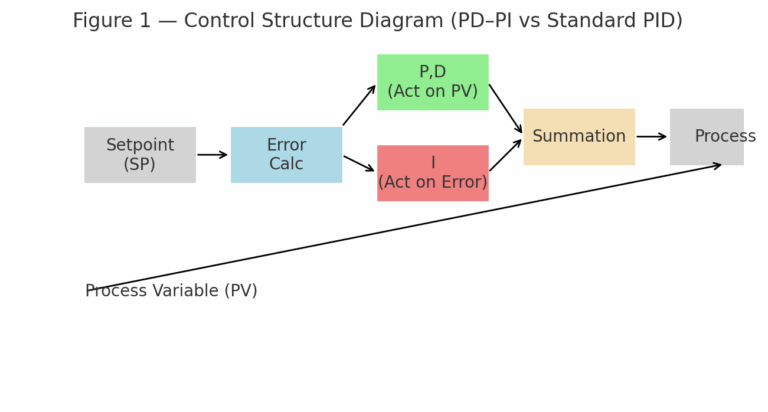

2. Structural Principle of PD–PI Control

Standard PID: Proportional (P), Integral (I), and Derivative (D) terms all act on the error signal (SP – PV).

PD–PI Control:

Integral term (I) still acts on the error signal.

Proportional and Derivative terms (P, D) act only on the process variable (PV), independent of SP changes.

This decoupling ensures that SP jumps do not generate large output disturbances.

3. Key Improvements over Standard PID

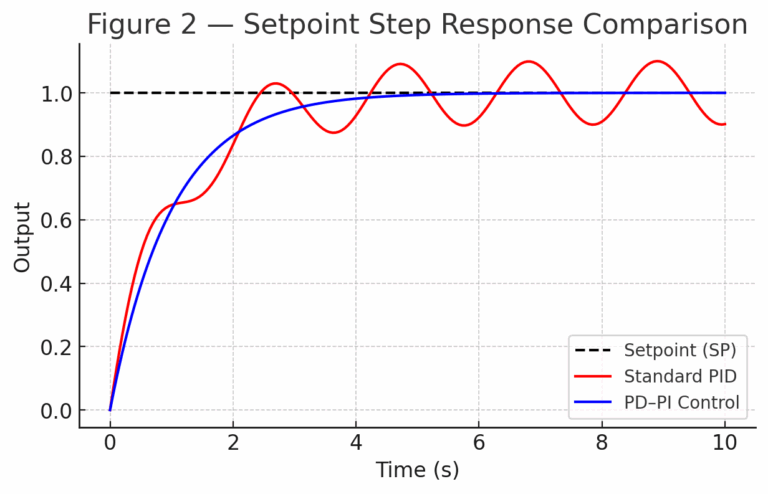

Elimination of Setpoint-Induced Overshoot

Standard PID: SP changes trigger large proportional and derivative responses.

PD–PI: P and D terms ignore SP changes, avoiding violent control output jumps.

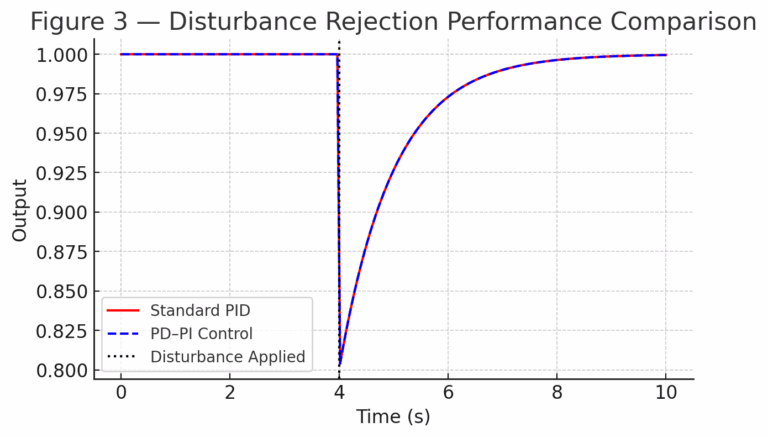

Maintained Disturbance Rejection

Both standard PID and PD–PI can suppress process disturbances effectively (e.g., load changes).

Smooth Setpoint Tracking

Transition to new SP values is smoother, minimizing oscillations and mechanical wear.

Table 1 — Response Comparison between Standard PID and PD–PI

| Aspect | Standard PID | PD–PI Control |

|---|---|---|

| Response to SP step change | Large overshoot, oscillation | Smooth, minimal overshoot |

| Response to disturbance | Effective | Effective |

| Valve/actuator stress | High | Low |

| Tracking accuracy | Acceptable | High |

4. Application Scenarios

PD–PI control is not a universal replacement but excels in scenarios where setpoint changes are frequent or critical:

Batch processes with frequent SP changes

(e.g., reactor temperature control, conveyor/packaging line speed transitions).High-precision SP tracking systems

(e.g., semiconductor temperature regulation, robotic servo position control).Systems sensitive to actuator saturation

(e.g., compressor surge control, injection molding machine pressure loops).Operator-intervention-heavy environments

(e.g., chemical plant commissioning, laboratory pilot plants).

⚠️ Limitation: Not suitable for systems requiring ultra-fast SP response, since PD–PI reacts slightly slower than standard PID to SP changes.

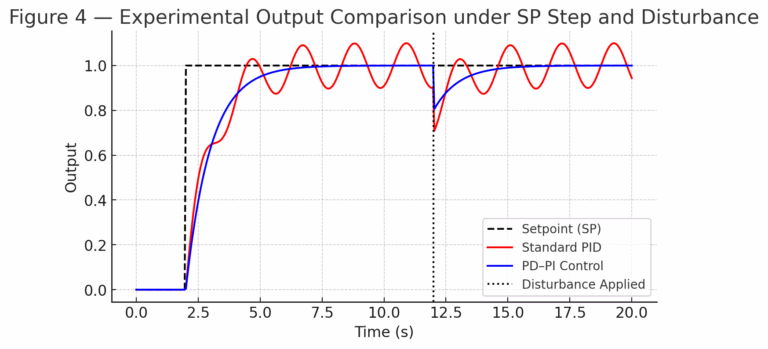

5. Case Illustration

In a comparative test:

Both controllers suppressed disturbances effectively.

However, under SP step changes, the standard PID output fluctuated sharply, while PD–PI maintained smoother control output.

6. Conclusion

The Proportional–Derivative First (PD–PI) Control strategy represents a practical improvement over standard PID by:

Eliminating violent responses to setpoint changes.

Preserving strong disturbance rejection capability.

Reducing mechanical wear on actuators.

It is particularly valuable for precision control systems with frequent setpoint changes, acting as a “gentle guardian” that balances control quality with equipment safety.