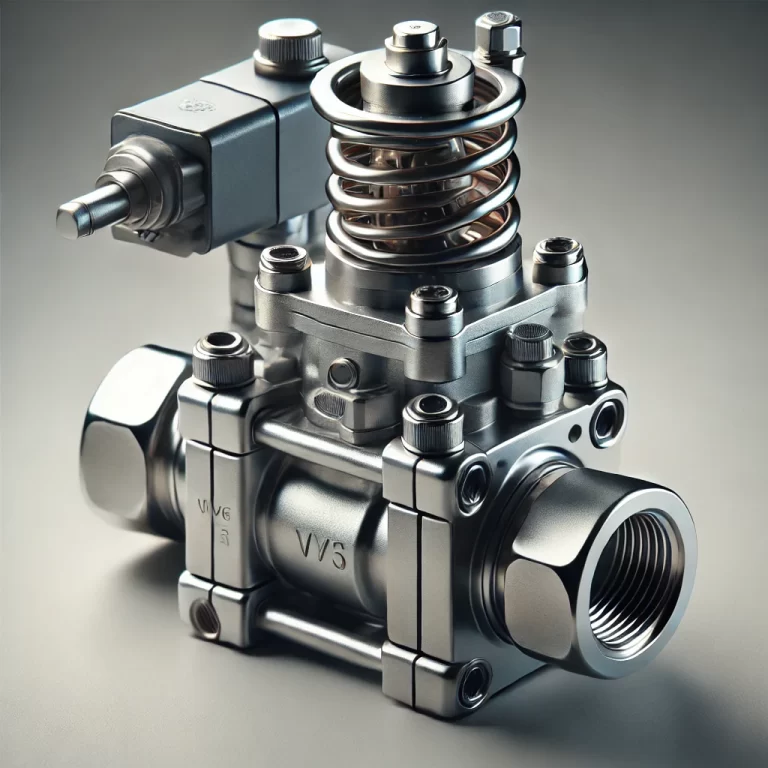

The quality of the solenoid valve depends mainly on two aspects, one is the coil and the other is the valve body, so the test mainly tests these two aspects. You find a 24V power supply and connect it to the coil. If you can hear a sound, it means that the coil and valve core of the solenoid valve are normal and can be sucked and closed normally.

Then check whether there is leakage. If there is an air source, it is best to connect the air source directly to determine whether there is leakage. If there is no air source, you can block the air outlet and blow it down with your mouth. In addition, the coil can also be checked with a multimeter.

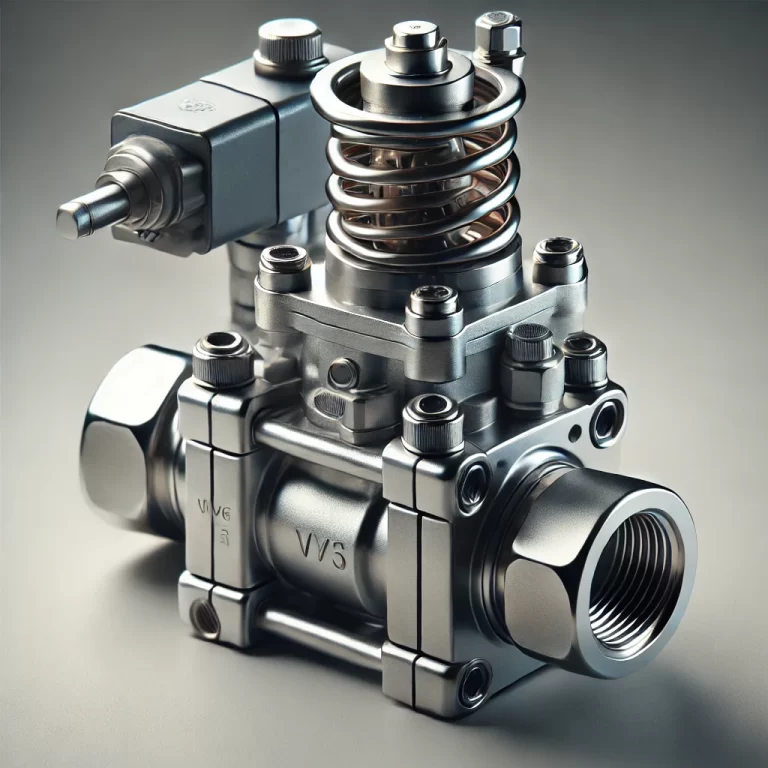

1. Power on the solenoid valve. Unplug the plug and use a multimeter to measure whether there is electricity.

2. Power on the solenoid valve. Put a thin steel wire close to the coil to see if there is suction.

3. Power on and off the solenoid valve repeatedly. Use a very thin Allen wrench to poke the brass “small pit” on the axis of the solenoid valve to see if it can be sucked in and ejected.

Methods for testing the quality of solenoid valves:

First, pass the controlled medium (pressurized liquid, gas <air>, the pressure value is the middle value of the solenoid valve’s operating pressure range) through the solenoid valve, and then energize the solenoid valve coil. If the controlled medium changes from on to off or from off to on, then the solenoid valve is good, otherwise there is a problem.

Common faults of solenoid valves:

1. Coil short circuit or open circuit:

Detection method: First use a multimeter to measure its continuity. If the resistance is close to zero or infinite, it means that the coil is short circuit or open circuit. If the resistance is normal (about tens of ohms), it does not mean that the coil is definitely good (I once measured a solenoid valve coil resistance of about 50 ohms, but the solenoid valve could not work. After replacing the coil, everything was normal). Please perform the following final test: Find a small screwdriver and place it near the metal rod that passes through the solenoid valve coil, then power on the solenoid valve. If you feel magnetism, then the solenoid valve coil is good, otherwise it is bad.

Treatment method: Replace the solenoid valve coil.

2. There is a problem with the plug/socket:

Fault phenomenon: If the solenoid valve is the kind with a plug/socket, there may be problems with the metal reed of the socket, wiring problems on the plug (such as connecting the power cord to the ground wire), etc., which may prevent the power from being sent to the coil. It is best to develop a habit: after the plug is plugged into the socket, tighten the fixing screw, and tighten the fixing nut on the coil after the valve core rod.

If the plug of the solenoid valve coil is equipped with an LED power indicator, then when using a DC power supply to drive the solenoid valve, it must be connected correctly, otherwise the indicator will not light up. In addition, do not interchange power plugs with LED power indicators of different voltage levels, which will cause the LED to burn out/the power supply (replace with a low-voltage plug) to short-circuit or the LED to emit very weak light (replace with a high-voltage plug).

If there is no power indicator, the solenoid valve coil does not need to distinguish polarity (unlike the transistor time relay with DC coil voltage and the intermediate relay with DC coil voltage with a diode/resistor leakage circuit in parallel on the coil <most of these intermediate relays are original Japanese>, which need to distinguish polarity).

Solution: Correct wiring errors, repair or replace plugs and sockets.

3. Valve core problem:

Fault phenomenon 1: When the pressure of the medium passed by the solenoid valve is normal, the solenoid valve does not respond at all when the red manual button of the solenoid valve is pressed (the pressure medium does not change on and off), indicating that the valve core must be broken.

Solution: Check whether there is a problem with the medium, such as whether there is a lot of water in the compressed air (sometimes the oil-water separator does not play a big role, especially when the pipeline design is poor, there will be a lot of water in the compressed air passed to the solenoid valve), and whether there are a lot of impurities in the liquid medium. Then remove the water or impurities in the solenoid valve and pipeline. If it still doesn’t work, please repair or replace the valve core, or simply replace the entire solenoid valve.

Fault phenomenon 2: After inspection, the coil is the original coil and the magnetism is normal when the coil is energized, but the solenoid valve still does not move (the function of the manual button of the solenoid valve may be normal at this time), indicating that the valve core is broken.

Solution: Please repair or replace the valve core, or simply replace the entire solenoid valve