Foreword

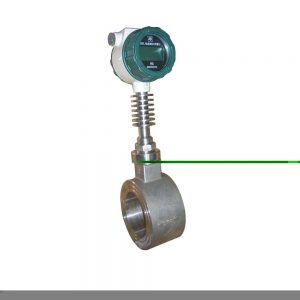

The measurement principle of the target flowmeter is: a target plate is set in the center of the circular measuring tube and the direction perpendicular to the flow beam, and the fluid flows along the annular gap around the target plate.

Due to the flow of the fluid, the force is generated on the target plate.

The flow rate is proportional to the square root of the force on the target plate. The flow rate can be calculated by detecting the magnitude of the force.

In the target flowmeter, the fluid flows through the annular space around the target plate, and the circulation space is large, which overcomes the defects of the positive displacement flowmeter and will not be blocked by the sediment.

At the same time, the target flowmeter has a low Reynolds number (2000~4000) and can be used for the measurement of higher viscosity media.

Therefore, the SBL series capacitive target flowmeter is more suitable for measuring crude oil.

According to the measurement principle of the target flowmeter, the volume flow rate of the fluid is inversely proportional to the square root of the fluid density.

For the measurement of pure and single liquid, when the temperature is constant, the density does not change, and no measurement error occurs.

The change in the density of crude oil due to the change in water content will cause certain measurement errors. When the error is too large, it needs to be corrected.

2.1 Density calculation of water-bearing crude oil

Although the measurement of fluid density is simple and quick, the water content of crude oil is often provided on-site instead of density.

It is easy to find detailed water cut records from oil field data and reports, so it is necessary to convert the water cut to density.

Crude oil and water are incompatible with each other. In the pipeline, free water and crude oil exist in layers, and emulsified water exists in the form of tiny particles.

The sand content of crude oil is generally very small and can be ignored. Therefore, the density of the oil-water mixture is a simple algebraic relationship, namely:

ρH=Psρs+(1- Ps) ρY

In the formula: ρH——The density of the mixed liquid, g/cm3;

ρs——water density, ρs=1.0 g/cm3;

ρY——The density of crude oil, ρY=0.80~0.95 g/cm3;

Ps——water content, %.

2.2 Calculation of measurement error

Calculate the measurement error according to the fluctuation range of the crude oil-water content, decide whether to correct the flowmeter, and what method to use.

The water content of crude oil transported from oil gathering stations and oil transfer stations is relatively stable, with fluctuations within ±5%, with small errors, and generally does not require correction.

For example, when a certain oil gathering station has a water content of 30%-40% in crude oil during a certain period, the flowmeter is calibrated according to the water content of 35% (density 0.916).

When the water content is 30% (density 0.909), the error is large. Since the flow rate is inversely proportional to the square root of the density, the error is:

(0.909-2- 0.916-2)/0.909-2=0.356%

Choose the flowmeter with accuracy class 1, the total measurement error is:

±1.0035×1.01=±1.0136

That is, the error is ±1.36%.

The actual measurement accuracy can reach 1.5, which is sufficient for internal oilfield settlement.

With the increase of oilfield exploitation time, the water content of crude oil gradually rises.

On some occasions, the water content cannot be controlled and fluctuates greatly, such as single-well metering. In these cases, density correction is required.

2.3 Density correction method

2.3.1 Direct calibration (hard correction)

Calibration is performed according to the actual density of the water-bearing crude oil. Generally, the calibration of the flowmeter requires a standard device.

In addition to using standard devices, target flowmeters can also be calibrated dry on-site, that is, using the weight hanging method, which is convenient and easy to implement.

When using the dry method to verify, first calculate the force F applied to the target plate at each flow point according to the following formula。

F =(Q/C)2/ρ

The coefficient C in the above formula is provided by the manufacturer, and ρ can be calculated or actually measured based on the water content of the crude oil.

The user can use the formula to sequentially calculate the corresponding relationship between the instantaneous flow rate Q within the flow range of the meter and the force F of the medium acting on the target, so as to calibrate the meter. The reading of the flowmeter is the actual flow.

2.3.2 Manual correction (soft correction)

Manually detect the density of crude oil or the water content of crude oil, and modify the meter coefficient.

The flowmeter is calibrated according to the water density ρ=1.000 g/cm3, the meter coefficient is C, the actual density ρ is calculated according to the water content, and then the density correction coefficient Kρ=1/ρ1/2 is calculated according to the density (or look-up table).

Change the meter coefficient to KρC, so that the reading of the flowmeter is the actual flow. The actual flow can also be obtained by multiplying the reading of the flowmeter by Kρ.

2.3.3 Real-time correction

The target flowmeter is matched with the online detection instrument (density meter or water content analyzer) and intelligent secondary instrument (or computer) for density correction, and it can also display the total amount of oil and water respectively.

The principle and calculation are the same as a manual correction. At present, there is no integrated density correction flowmeter, which needs to be configured by the user.

The method is similar to the temperature and pressure compensation of gas measurement, so I will not repeat it.

This correction method is suitable for occasions with high measurement accuracy requirements, large fluctuations in water content, and frequent fluctuations.