Introduction to Equipment Inspections

The equipment inspection system is a management method where specific parts of equipment are checked periodically according to certain standards to detect potential faults early. This allows for timely repairs and adjustments, ensuring that the equipment maintains its prescribed functions. It’s important to note that equipment inspection is not just a check, but also a system and management practice.

Before delving into the specifics of inspections, let’s categorize the equipment and go over the basic checks for each category.

Types of Equipment and Basic Checks

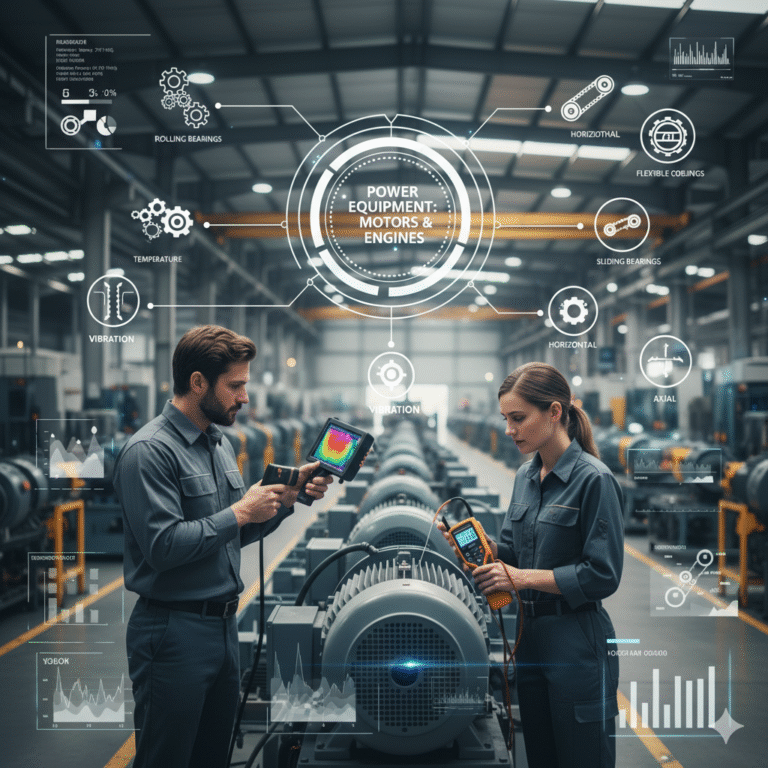

Power Equipment (including motors, internal combustion engines, steam engines, and power units used in areas without electricity): These devices often function as the driving end of a system, connecting to other equipment using couplings, chains, belts, rigid or membrane drives.

Almost all rotating equipment suffers from two core issues: high temperatures and excessive vibration. Let’s explore how these two factors impact the equipment.

Impact of Temperature on Power Equipment:

When the temperature increases, metal parts expand, affecting components such as bearings, which are highly sensitive to temperature. There are two main types of bearings: rolling bearings and sliding bearings.Rolling Bearings: They are cost-effective, generate less heat, and are easier to lubricate. However, their load-bearing capacity is lower.

Sliding Bearings: They handle higher loads, but are more complex to lubricate, generate more heat, and are more expensive.

Effect of High Temperatures: When the temperature rises, the internal and external rings of rolling bearings expand. This causes the lubricant to thin, reducing its ability to adhere to metal surfaces, leading to increased friction and wear.

Vibration in Rotating Equipment:

Mechanical vibration refers to the regular oscillating movement of an object from its equilibrium position. Vibration can be categorized as:Horizontal Vibration: Similar to the left-right movement of a fish’s tail.

Vertical Vibration: Similar to the up-and-down movement of a bird’s wings.

Axial Vibration: Similar to the back-and-forth motion of a piston.

Excessive vibration in motors can be detected using specific instruments to measure horizontal, vertical, and axial vibrations.

Inspection Methods: “Look, Listen, Ask, Measure”

When inspecting a motor, the following approach is used:

Look: Check the motor nameplate to identify the motor speed. Motor speed can generally fall into three ranges:

500-1000 rpm

1000-1500 rpm

1500-3000 rpm

Use the motor speed to gauge if the vibration and temperature are within acceptable limits.

Listen: Smell the motor for any burning odors, which may indicate overheating insulation or lubricant degradation.

Ask: Use a thermometer to measure the motor temperature, especially at the bearing positions. Listen for abnormal sounds—healthy bearings make a smooth, clear sound.

Measure: Use a vibration meter to check the motor’s vibration levels.

Standard Motor Inspection Values

For motors with speeds of 500-1000 rpm: Temperature should not exceed 60-70°C, and vibration should be less than 0.1mm.

For motors with speeds of 1000-1500 rpm: Temperature should not exceed 70-80°C, and vibration should be under 0.07mm.

For motors with speeds of 1500-3000 rpm: Temperature should not exceed 80-90°C, and vibration should be below 0.05mm.

If any of these thresholds are exceeded, it’s time to report the issue for repairs.

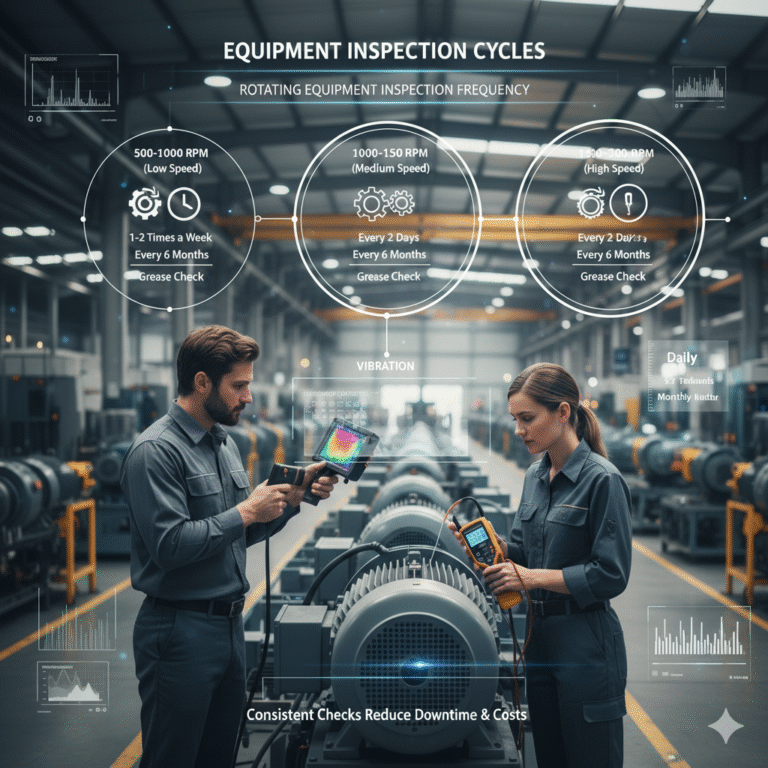

Equipment Inspection Cycles

The frequency of inspections varies depending on the speed and type of equipment. For rotating devices, the general inspection periods are:

For 500-1000 rpm: Inspection should be done 1-2 times a week, and grease should be checked at least every 6 months.

For 1000-1500 rpm: Inspection should be done every 2 days, with grease checked at least every 3 months.

For 1500-3000 rpm: Inspections should be conducted daily, with grease checked at least monthly.

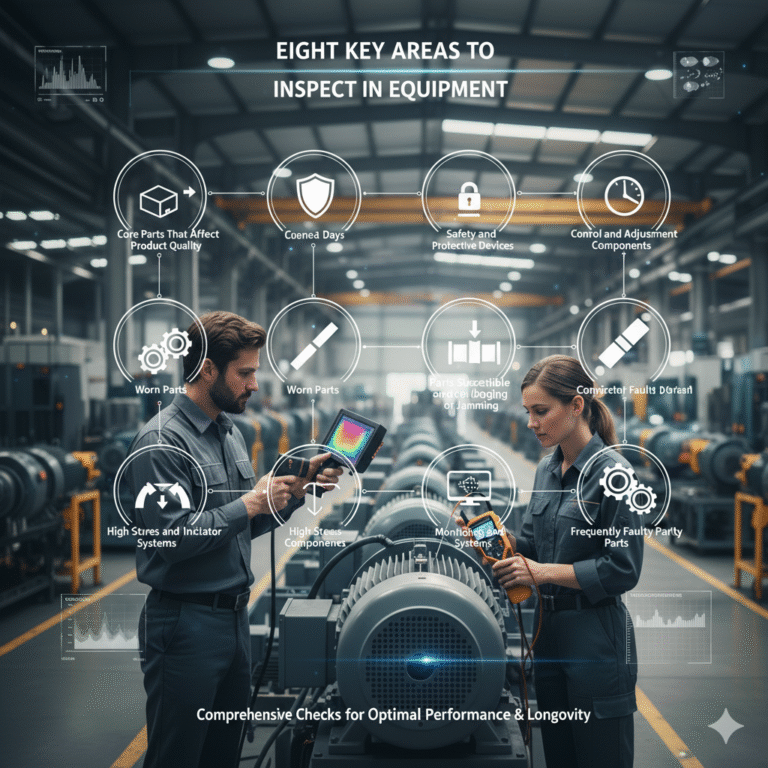

Eight Key Areas to Inspect in Equipment

Core Parts That Affect Product Quality: These parts directly impact product quality. Pre-operation checks ensure that no damage, contamination, or foreign materials are present.

Safety and Protective Devices: These ensure the safety of personnel and prevent equipment overload. They must be checked before startup to confirm proper functionality.

Control and Adjustment Components: These components regulate critical operational parameters such as temperature, pressure, and speed. They need regular calibration to ensure accuracy.

Worn Parts: These parts experience high wear and tear. They should be inspected for visible signs of damage such as cracks, deformation, and excessive noise during operation.

Parts Susceptible to Clogging or Jamming: These components can accumulate debris, affecting equipment function. Regular cleaning and checks are necessary to prevent blockages and ensure smooth operation.

High-Stress Components: Parts that bear the highest loads during operation are vulnerable to cracks and deformation. Regular checks for signs of wear are crucial.

Monitoring and Indicator Systems: Instruments that display operational data need to be verified for accuracy. If any anomalies are detected, they should be inspected for potential system failures.

Frequently Faulty Parts: Parts that are prone to failure due to design or operational history should be inspected more frequently and thoroughly.

Conclusion

Equipment inspections don’t have to be time-consuming and can often be completed in 10-15 minutes before starting operations. Regular inspections can help identify issues early, preventing minor problems from escalating into major breakdowns, reducing unplanned downtime, and lowering maintenance costs.

In industrial operations, minimizing downtime and ensuring continuous production are key to improving efficiency. By maintaining equipment stability, you can ensure product quality and streamline production processes, reducing both worker strain and safety risks.