In industries such as chemical engineering, environmental protection, pharmaceuticals, municipal projects, and energy, pump selection is one of the most critical steps during the design phase. Proper pump selection directly impacts the operational safety, energy efficiency, and overall cost-effectiveness of the system.

Through consultations with experienced professionals in design institutes, we have summarized the key principles of pump selection. It is essential to follow the guiding principles of “technical feasibility, economic rationality, safety and reliability, and operational efficiency”. A scientific match can be achieved through systematic calculations and standardized processes.

This guide provides a thorough explanation of the logic and methodology behind scientific pump selection from a design perspective. Key factors include process parameters, pump types, media compatibility, energy efficiency optimization, standards, and design considerations. We also incorporate engineering examples for clarity.

Basic Premise for Pump Selection

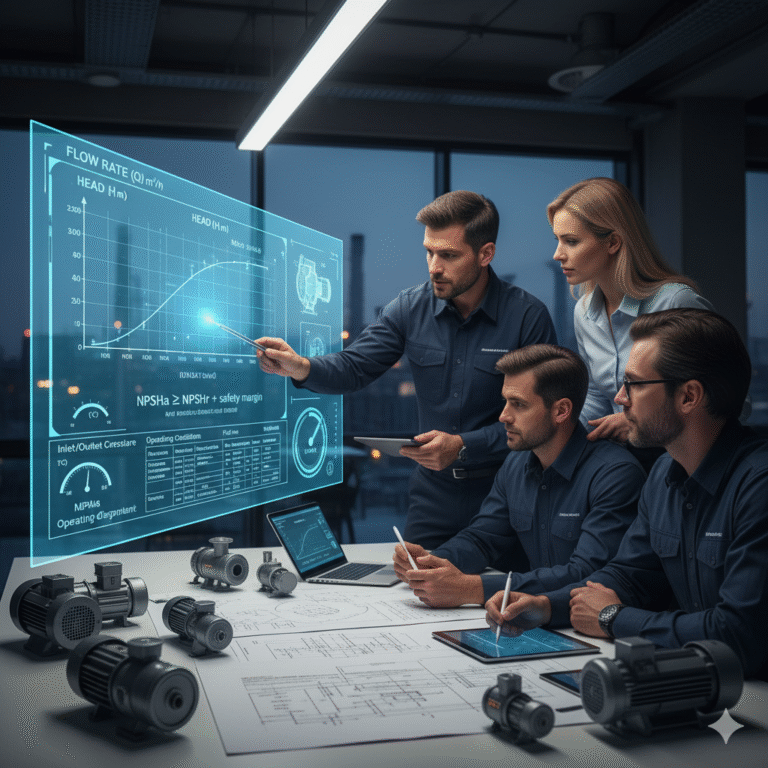

During the design phase, the key parameters for selecting a pump are provided by the process engineering team. These parameters serve as the foundation for pump selection. The critical process parameters include:

Flow rate (Q) (m³/h): Clearly define the minimum, normal, and maximum flow rates. When selecting a pump, the rated flow is generally set at 1.1 times the normal flow to accommodate fluctuations. For systems with wide flow variations, consider using variable frequency drives or parallel pump configurations.

Head (H) (m): The total head is the sum of static head, friction losses, and local resistance. The rated head is typically 1.05–1.1 times the system calculated value to ensure a safety margin. Both “calculated head” and “rated head” should be clearly stated in design documents for verification.

Inlet/Outlet Pressure & System Resistance: The inlet and outlet pressure affect the pump casing strength, mechanical seals, and shaft seals. High-pressure systems must also be evaluated for water hammer and include safety valves.

Temperature (T) (°C): Provide the normal, maximum, and minimum temperatures for the media. Temperature affects materials, cooling systems, and seal structures. For high-temperature media, select pumps with mechanical seals equipped with cooling chambers.

Net Positive Suction Head (NPSHa): It is essential to ensure that:

NPSHa ≥ NPSHr + safety margin (0.5–1.0m)

If this condition is not met, consider lowering the installation height, increasing the suction pipe diameter, or selecting a pump with a lower NPSHr.

Operating Conditions and Environmental Factors: Include operational mode (continuous or intermittent), installation environment (indoor/outdoor, ambient temperature, humidity, explosion-proof ratings, and atmospheric corrosiveness).

Pump selection should consider equipment layout, motor coordination, explosion-proof requirements, and pipeline routing to avoid isolated, parameter-driven selection.

Selection Principles

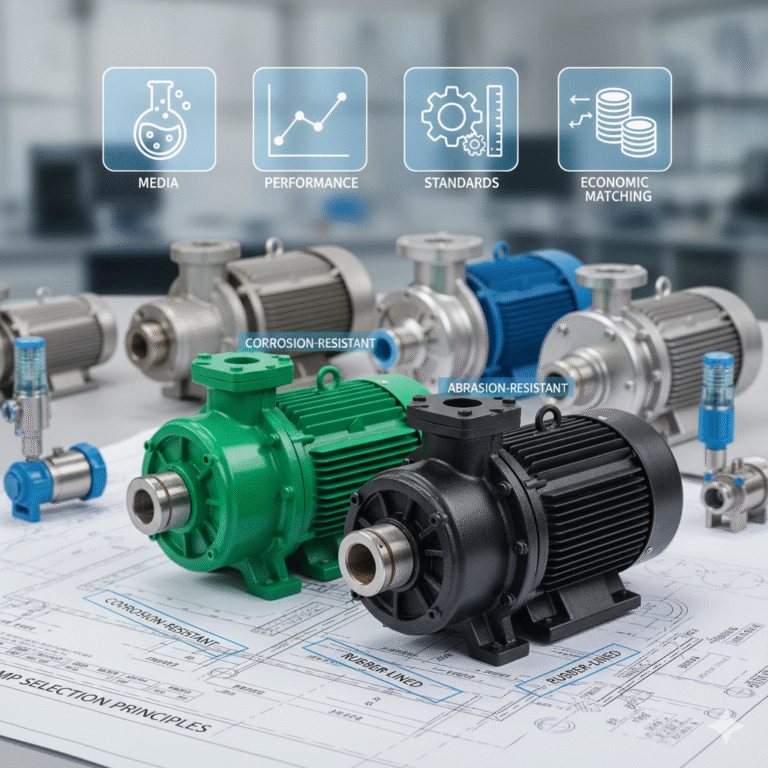

Design institutes emphasize “media, performance, standards, and economic matching” in pump selection.

Physical and Chemical Properties of the Media:

The primary factors to consider are:

Corrosiveness (acids, alkalis, chlorine ions, etc.)

Abrasiveness (solid particles, slurries)

Viscosity (for fluids with viscosity >650 mm²/s, positive displacement pumps are recommended)

Gas content and vapor pressure

Toxicity and safety requirements

Example: A pump used for transporting sodium chloride solution (solid content 10%, particle size 0.12mm) from a three-effect evaporator should be a fluoroplastic alloy centrifugal pump or a rubber-lined wear-resistant pump, which combines both corrosion and abrasion resistance.

Pump Type Selection Guidelines

| Working Conditions | Recommended Pump Type | Features & Rationale |

|---|---|---|

| Regular liquid transport | Centrifugal pump | Mature design, high efficiency, easy maintenance |

| Precise metering required | Metering pump | Accurate flow control, no pulsation |

| High head, low flow | Multi-stage or reciprocating pump | Suitable for high-pressure systems |

| Solid or slurry transport | Screw or slurry pump | Anti-clogging, wear-resistant |

| High-viscosity fluids | Rotary or gear pump | Low shear, operates at low speed |

| Gas-containing liquids | Vortex pump | Excellent anti-cavitation performance |

| Frequent start/stop | Self-priming centrifugal pump | No priming required, simple maintenance |

Pump Selection for Specific Media

Clear Water Pumps: Suitable for urban water supply and cooling systems, e.g., IS type centrifugal pumps for temperatures ≤80°C.

Corrosion-Resistant Pumps: For transporting acidic, alkaline, or saline solutions, e.g., IHF fluoroplastic centrifugal pumps or 316L stainless steel pumps.

Leak-Free Pumps: Used for toxic or high-purity media, such as in pharmaceutical or electronics industries, e.g., magnetic drive or shielded pumps to eliminate leakage risks.

Low NPSH Pumps: Suitable for media like LPG or propylene that are prone to vaporization. Recommended options include tubular pumps or low NPSHr centrifugal pumps.

Installation Method Considerations for Pump Selection

| Installation Method | Application Scenario | Description |

|---|---|---|

| Horizontal Pump | Fixed installation in pump rooms | Low center of gravity, easy maintenance |

| Vertical Sump Pump | Sewage pits, corrosive liquid tanks | Space-saving, prevents motor corrosion from liquids |

| Vertical Inline Pump | Fire fighting, HVAC systems | Direct pipeline connection, space-efficient |

| Submersible Pump | Deep wells, drainage systems | Suitable for submerged operation |

The pump layout should be coordinated with pipeline routing, maintenance space, and accessibility to ensure a holistic system design.

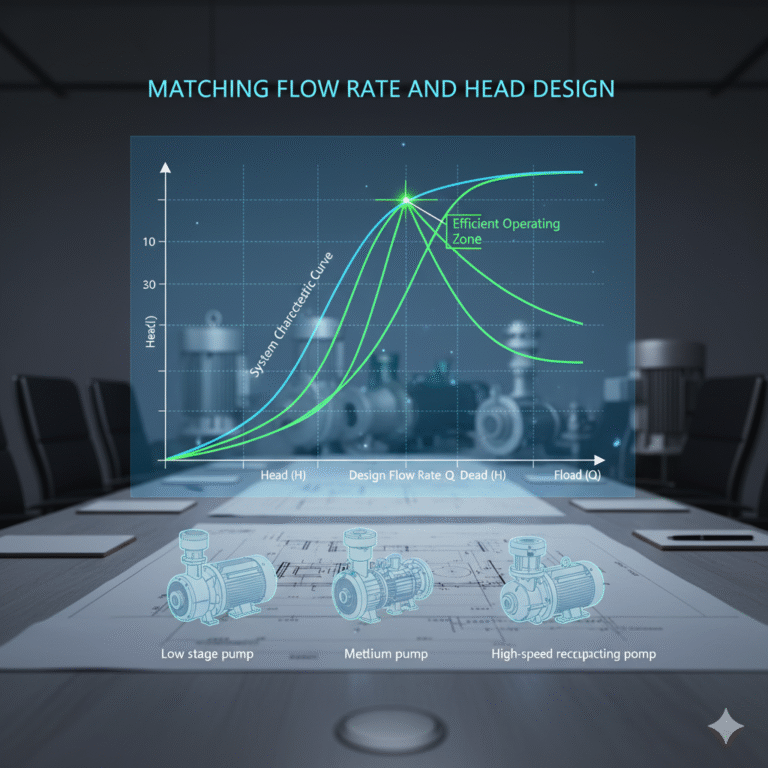

Matching Flow Rate and Head Design

Flow Range:

Small Flow (<20m³/h): Single suction pump or magnetic pump.

Medium Flow (20–200m³/h): Multi-stage centrifugal pump.

Large Flow (>500m³/h): Double-suction or axial flow pump.

Head Levels:

Low Head (≤40m): Single-stage centrifugal pump.

Medium Head (40–120m): Multi-stage pump.

High Head (>120m): High-speed or reciprocating pump.

System characteristic curves and pump performance curves should be plotted to ensure that the operating point falls within the efficient zone (η ≥ 85%).

Energy Efficiency and System Optimization Design

During the selection phase, consider both the system’s energy efficiency and economic feasibility:

Efficient Zone Operation: The operating point should be as close to the rated conditions as possible.

Variable Frequency Control: Use variable frequency drives to adjust flow and reduce throttling losses.

Series and Parallel Optimization: Use parallel configurations for variable flow systems and series for high head applications.

Pipeline Resistance Optimization: Minimize the number of elbows and valves, and choose pipe diameters wisely.

Lifecycle Cost (LCC) Evaluation: Consider not only procurement costs but also energy consumption, maintenance, and downtime costs.

Standards and Quality Control for Pump Selection

Adhere to relevant standards when selecting pumps:

General pumps: GB/T3215, GB/T5656

Chemical process pumps: API610

Explosion-proof pumps: GB3836 series

Hygienic pumps: Compliant with GMP/FDA standards

In the review process, API610 process pumps are often given priority to ensure durability, interchangeability, and international standard compliance.

Conclusion: The Logic Behind Pump Selection

Pump selection is a highly comprehensive system engineering process. In a scientific approach, a qualified pump should meet:

Process compatibility

Energy efficiency

Safety and reliability

Standard compliance

Operational and maintenance economics

Only by achieving the “optimal solution over the entire lifecycle” during the design phase can the pump system achieve efficient, reliable, and sustainable operation.