Pneumatic control valves are essential components in industrial automation systems. They regulate process parameters like flow rate, pressure, and temperature by receiving pressure signals (usually 0.02-0.1 MPa or 3-15 psi) from controllers (such as DCS or PLC). The selection of the right pneumatic control valve is crucial for system efficiency and performance. Below, we categorize and explain the most common types of pneumatic control valves, their characteristics, and typical applications.

1. Types of Pneumatic Control Valves

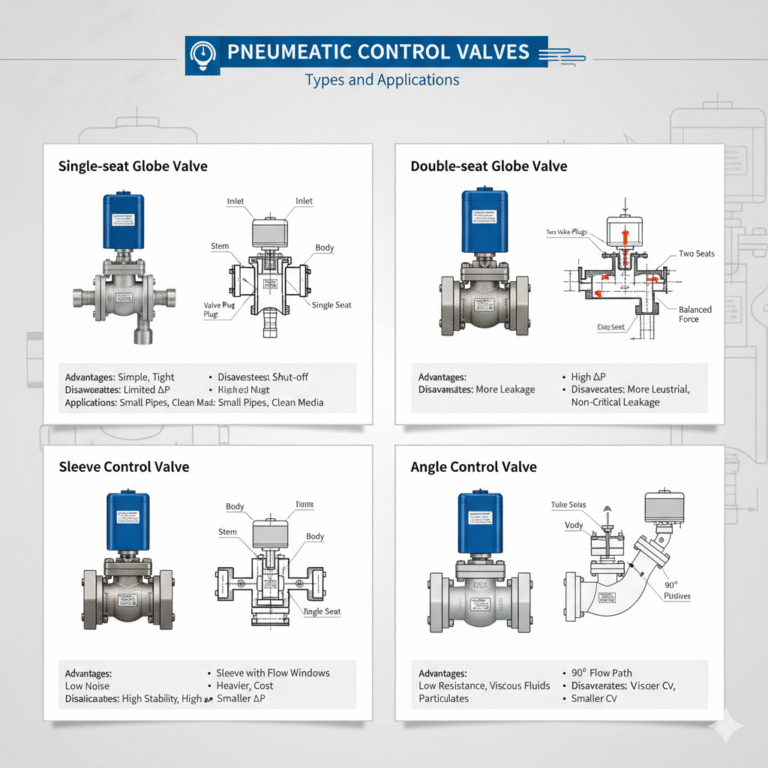

Pneumatic Globe Control Valve (Single-seat)

Structure: Single valve core and seat.

Advantages: Simple structure, excellent sealing (minimal leakage), can achieve shut-off.

Disadvantages: Large imbalance force, limiting differential pressure.

Applications: Small pipe diameters (DN < 25mm), low differential pressure, clean media.

Pneumatic Globe Control Valve (Double-seat)

Structure: Two valve cores and two seats.

Advantages: Low imbalance force due to opposing fluid thrust, handles larger differential pressure.

Disadvantages: Complex manufacturing, higher leakage compared to single-seat valves.

Applications: High differential pressure, non-critical leakage applications, common in industrial use.

Pneumatic Sleeve Control Valve

Structure: Based on the double-seat valve but with sleeve and valve plug design. The sleeve has functional windows.

Advantages: Good stability, low noise, broad adaptability (can be modified by changing sleeves).

Disadvantages: Heavier, slightly higher cost.

Applications: High stability, low-noise requirements, high differential pressure.

Pneumatic Angle Control Valve

Structure: 90-degree inlet and outlet.

Advantages: Low flow resistance, suitable for viscous fluids or media with suspended particles.

Disadvantages: Smaller flow coefficient.

Applications: Applications with crystallizing or particulate media, high differential pressure.

Pneumatic Three-way Control Valve

Structure: Three ports, split or combine fluid paths.

Advantages: Flexible fluid flow control for merging or splitting streams.

Applications: Heat exchangers, temperature control, ratio control.

Pneumatic Butterfly Valve

Structure: Circular disc rotates in the valve body to adjust flow.

Advantages: Compact, lightweight, cost-effective, suitable for large-diameter valves.

Disadvantages: Larger leakage (improved performance with eccentric designs).

Applications: Large flow, low differential pressure, gas or liquid control in ventilation and water systems.

Pneumatic V-Ball Valve

Structure: V-shaped notch in the ball adjusts flow when rotated.

Advantages: High shear force, large adjustable range, excellent sealing, ideal for slurry or particulate media.

Disadvantages: Higher cost compared to standard ball valves.

Applications: Pulp, sewage, slurry processes.

Pneumatic Diaphragm Control Valve

Structure: Uses a flexible diaphragm to isolate the flow path and actuator.

Advantages: Low flow resistance, no leakage, corrosion-resistant.

Disadvantages: Diaphragm is prone to wear, limited pressure and temperature range.

Applications: Strong acids, corrosive, toxic or high-purity media.

2. Actuator Types

The actuator is the “muscle” of the valve, responsible for generating the force to move the valve stem.

Diaphragm Actuators: Common and simple, producing a force by air pressure on a diaphragm. Suitable for small travel lengths.

Piston Actuators: Generates larger force and stroke, ideal for high differential pressures or large valves.

Rack-and-Pinion Actuators: Converts linear motion from the piston into rotary motion. Used with butterfly or ball valves for larger torque output.

3. Action Type Classification

This refers to how the valve responds when the signal pressure increases:

Air-to-Open (Fail-Close): The valve opens with signal pressure and closes when there is no signal. Often used for safety-critical applications where the valve must close during signal loss.

Air-to-Close (Fail-Open): The valve closes with signal pressure and opens without it. Typically used when the valve must remain open in case of signal loss.

4. Valve Accessories

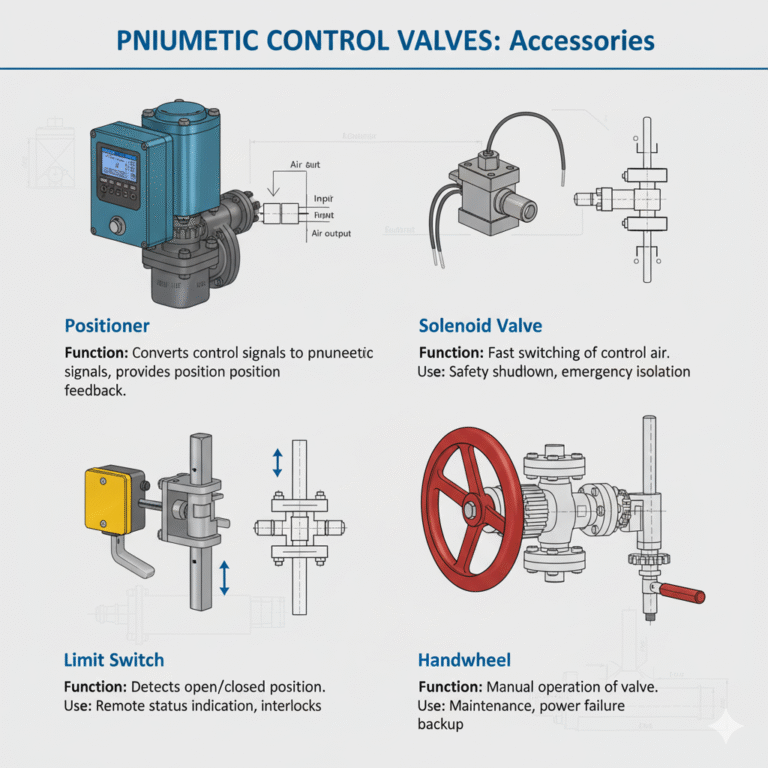

Accessories enhance the valve’s functionality and control precision:

Positioner: Converts control signals into pneumatic signals to drive the actuator and provides feedback on valve position.

Solenoid Valve: Used for fast switching of the control air supply, enabling safety shutdowns.

Limit Switch: Displays the open/closed position remotely.

Locking Valve: Holds the valve position when air pressure is insufficient, ensuring the valve stays in the previous position.

Handwheel: Used for manual operation when air pressure is unavailable.

5. Selection Recommendations

When selecting a pneumatic control valve, consider the following factors:

Medium Characteristics: Type of fluid (liquid, gas, steam), corrosiveness, viscosity, or particle content. This influences material and structural choice (e.g., diaphragm or V-ball valve).

Process Parameters: Flow rate, temperature, pressure, differential pressure. These determine the valve size, pressure rating, and actuator force needed.

Control Requirements: Precision, leakage tolerance, adjustable range, and flow characteristics (linear, equal percentage).

Safety Considerations: The valve’s behavior during failure (fail-close or fail-open).

Cost-effectiveness: Choose the best balance between cost and performance, ensuring all process needs are met.