Selecting a suitable non-contact level meter for wastewater is essentially about matching the instrument to the operating conditions. You can follow a simple four-step approach:

Clarify conditions → Select instrument type → Verify key parameters → Avoid common mistakes

1. Identify the Three Key Selection Factors

(1) Process Conditions

| Item | What to Check | Why It Matters |

|---|---|---|

| Medium Characteristics | Solids content, foam thickness, viscosity, pH | Affects signal reflection and material compatibility |

| Environment | Tank depth, open-air installation, humidity, electromagnetic interference | Determines range, housing protection and stability |

| Installation Space | Mounting position, obstacles (pipes, mixers) | Avoid signal blockage and false readings |

(2) Performance Requirements

Required measurement accuracy

Response speed

Stability under foam and suspended solids

Continuous monitoring vs. process control

(3) Signal / Integration Requirements

Confirm how the instrument will communicate:

4-20 mA analog output

RS-485 (Modbus RTU)

Wireless (LoRa / NB-IoT)

Whether it needs to connect to PLC / SCADA

2. Match the Correct Instrument to the Working Conditions

1) Ultrasonic Level Meter (Recommendation for Standard Municipal Sewage)

Best for:

Life sewage tanks, low-corrosion water, tank depth ≤ 15 m, limited foam

Advantages:

Cost-effective

Easy to install and maintain

Selection Notes:

Choose IP67 or higher, with temperature compensation + foam filtering algorithm.

2) Radar Level Meter (Recommendation for Industrial and Harsh Wastewater)

Best for:

High-corrosion wastewater, heavy foam, stirring/flow turbulence, tank depth > 15 m, electromagnetic interference environment

| Scene | Recommended Radar Type | Reason |

|---|---|---|

| General industrial wastewater | 26 GHz Radar | Good stability and cost balance |

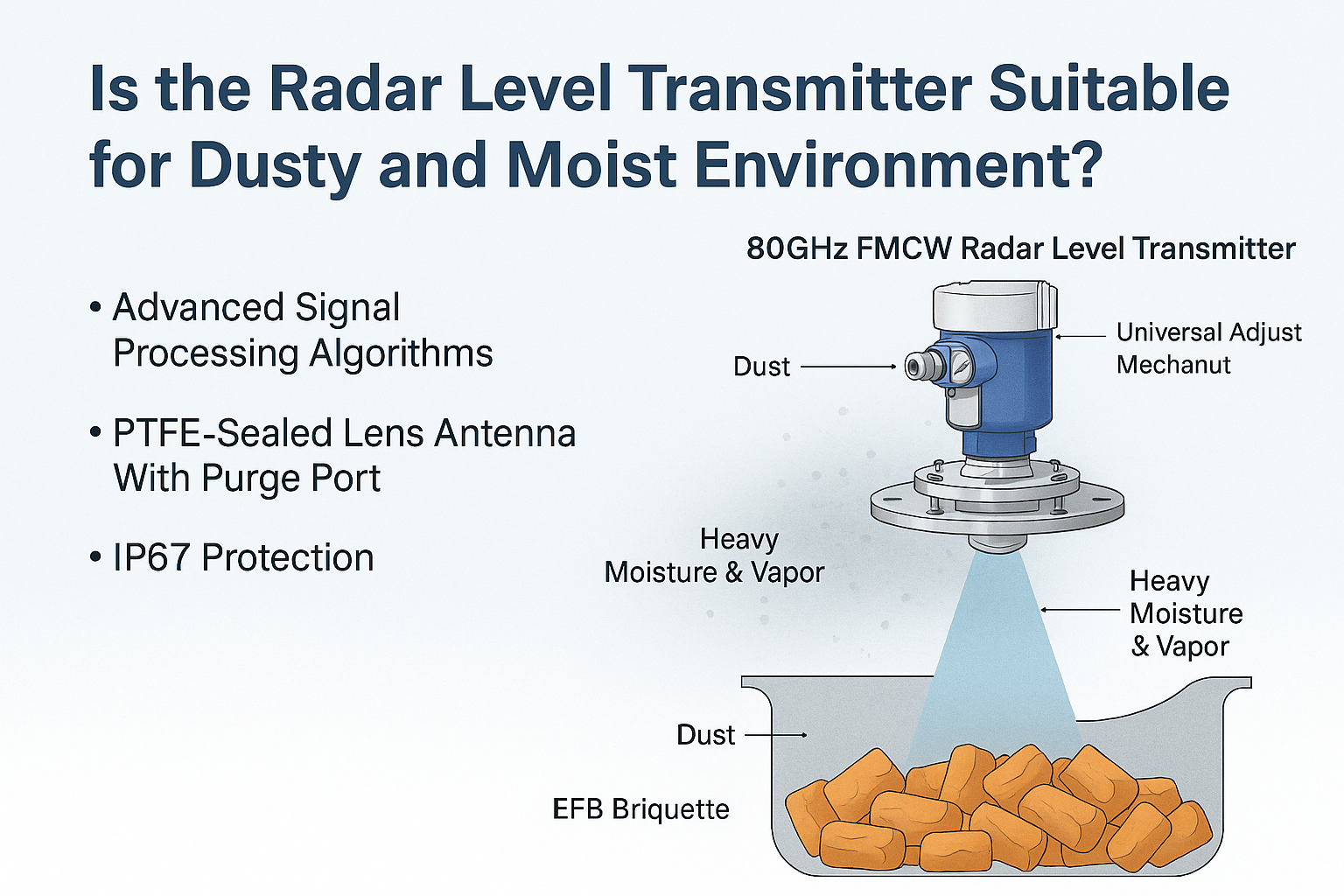

| Thick foam / viscous medium | 80 GHz FMCW Radar | Strong anti-interference, focuses signal better |

Advantages:

Not affected by foam, pressure, temperature, suspended solids.

Material Suggestion:

316L stainless steel or PTFE antenna.

3) Laser Level Meter (For Small Tanks & High Response Speed Requirements)

Best for:

Small adjustment pools, pilot test systems, fast level fluctuation detection (±0.5 mm precision).

Note:

Works best when there is no heavy dust or splashing directly in the optical path.

3. Verify These 5 Key Parameters Before Finalizing

| Parameter | Requirement | Why |

|---|---|---|

| Measuring Range & Blind Zone | Tank depth must fall outside blind zone | Prevent “zero reading” near surface |

| Output Signal | 4-20mA / RS-485 / wireless | Avoid compatibility issues later |

| Housing & Protection | At least IP67 outdoors | Prevent corrosion and moisture damage |

| Material | 316L / PTFE / anti-corrosion coatings | Critical for chemical wastewater |

| Power Supply | AC / DC / solar | Choose according to site availability |

4. Common Selection Mistakes to Avoid

| Mistake | Result | Correct Approach |

|---|---|---|

| Choosing ultrasonic meters in tanks with thick foam | Signal scattering → Level fluctuation | Use radar instead |

| Ignoring electromagnetic interference (e.g., VFD pumps) | Signal instability | Use radar + proper grounding/shielding |

| Not considering blind zone and installation height | Meter cannot read near surface | Pre-confirm installation dimensions |

10-Second Quick Selection Table

| Site Condition | Recommended Instrument | Reason |

|---|---|---|

| Standard municipal wastewater, shallow tank | Ultrasonic | Economical and practical |

| Industrial wastewater + foam + mixing | 80 GHz Radar | Stable and reliable |

| Small tank + fast level response needed | Laser Level Meter | High precision |