Selecting the right level transmitter for small-diameter storage tanks is crucial for accurate liquid level measurement and operational efficiency. With various technologies available, choosing the most suitable option depends on the storage medium, environmental conditions, and required measurement precision. In this article, we will explore the key factors that influence the selection of level transmitters for small-diameter storage tanks and provide recommendations based on common industry needs.

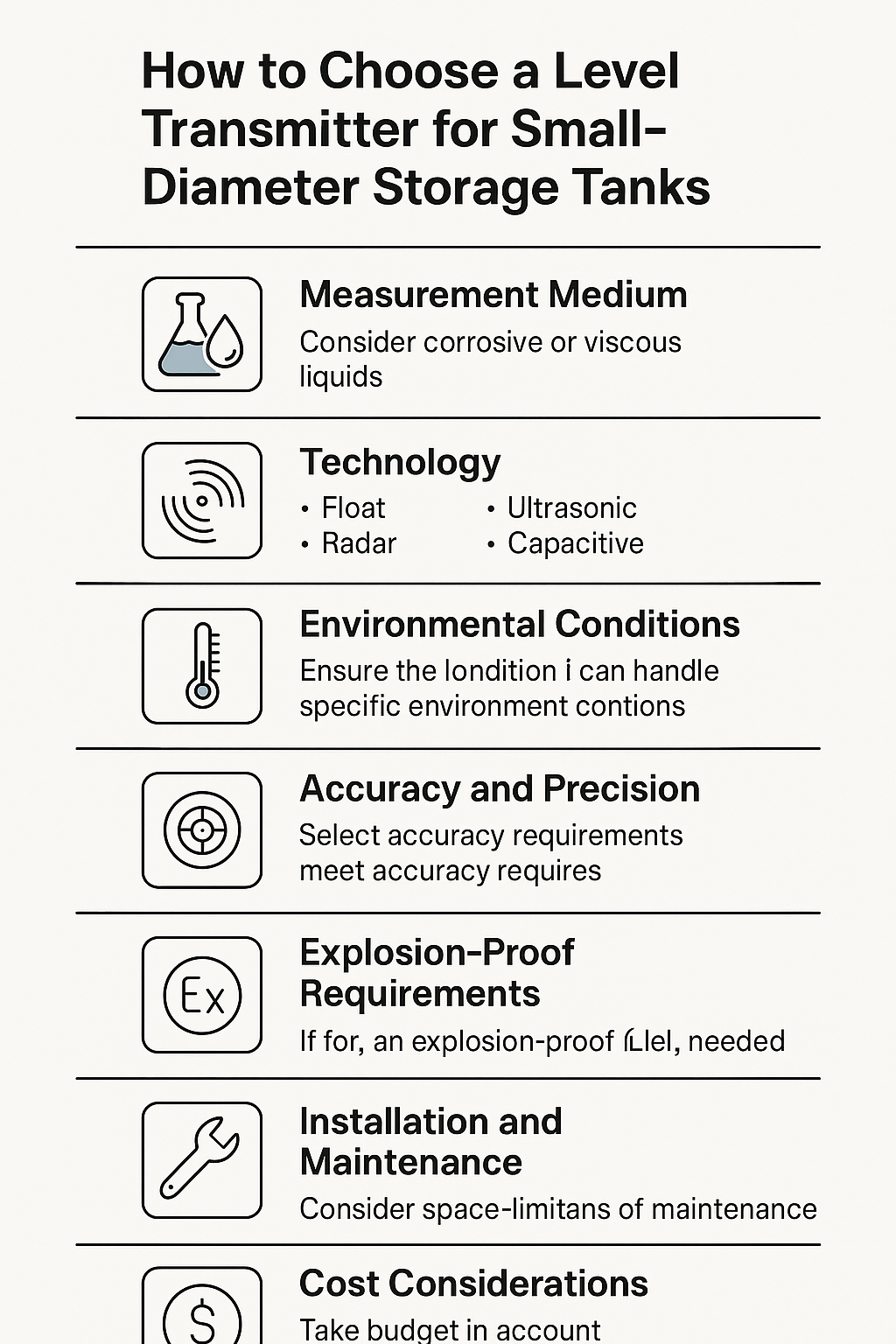

1. Understanding the Measurement Medium

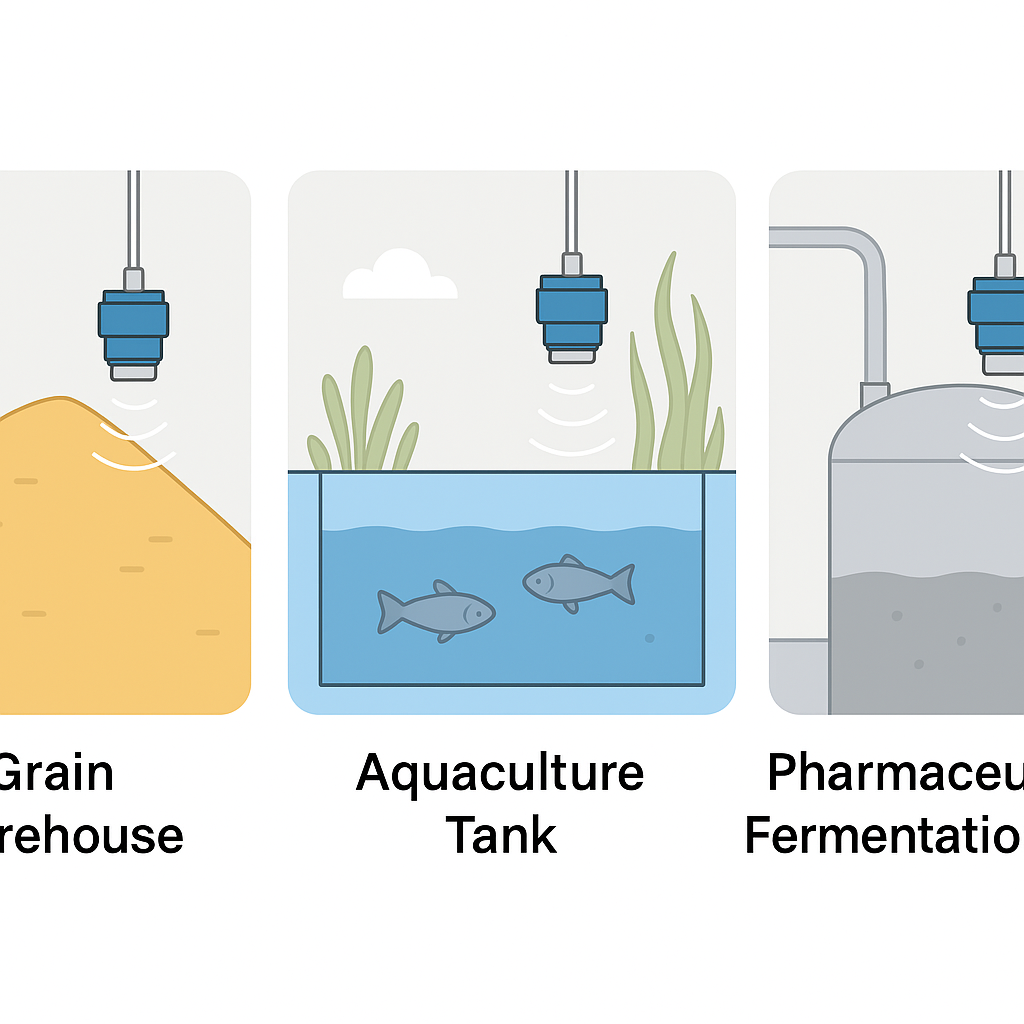

The type of liquid being stored in the tank plays a significant role in choosing the right level transmitter. Storage tanks can contain a wide variety of liquids, including chemicals, oils, and even food-grade liquids, each with its own set of challenges.

Corrosive Liquids: If the storage tank contains aggressive chemicals (e.g., acids or alkalis), the level transmitter must be resistant to corrosion. Materials such as PTFE or 316 stainless steel are often used for this purpose.

Viscous Liquids: For thicker or more viscous liquids, specialized level transmitters are necessary to ensure accurate measurements. Some technologies, such as float-based systems, may not work well with high-viscosity fluids, while radar-based sensors perform better in such conditions.

2. Choosing the Right Technology

There are several technologies available for measuring liquid levels. The ideal choice depends on the specific requirements of the application, including accuracy, environment, and installation constraints.

Float-based Level Transmitters

Best for: Simple applications where high precision is not a critical requirement.

Advantages: Reliable and easy to install.

Considerations: Best suited for non-corrosive, low-to-medium viscosity liquids in open systems.

Radar Level Transmitters

Best for: High-accuracy measurements in small-diameter storage tanks, especially in complex environments.

Advantages: Immune to temperature, pressure, and vapor variations. Ideal for tanks containing volatile, corrosive, or high-density liquids.

Considerations: Higher initial cost but offers long-term reliability and accuracy.

Ultrasonic Level Transmitters

Best for: Non-contact measurement in clean, low-pressure environments.

Advantages: Cost-effective and easy to install.

Considerations: May struggle with steam, foam, or turbulent liquids, making them unsuitable for certain harsh environments.

Capacitive Level Transmitters

Best for: Transparent and clean liquids where high precision is not required.

Advantages: Simple design, lower cost.

Considerations: Can be affected by the dielectric properties of the liquid.

Guided Wave Radar (GWR)

Best for: Small-diameter tanks with varying vapor or foam presence.

Advantages: Accurate in high-temperature, high-pressure, and fluctuating environmental conditions. Can measure liquids with foam or turbulence.

Considerations: More expensive than ultrasonic or capacitive options but provides precise measurement in challenging conditions.

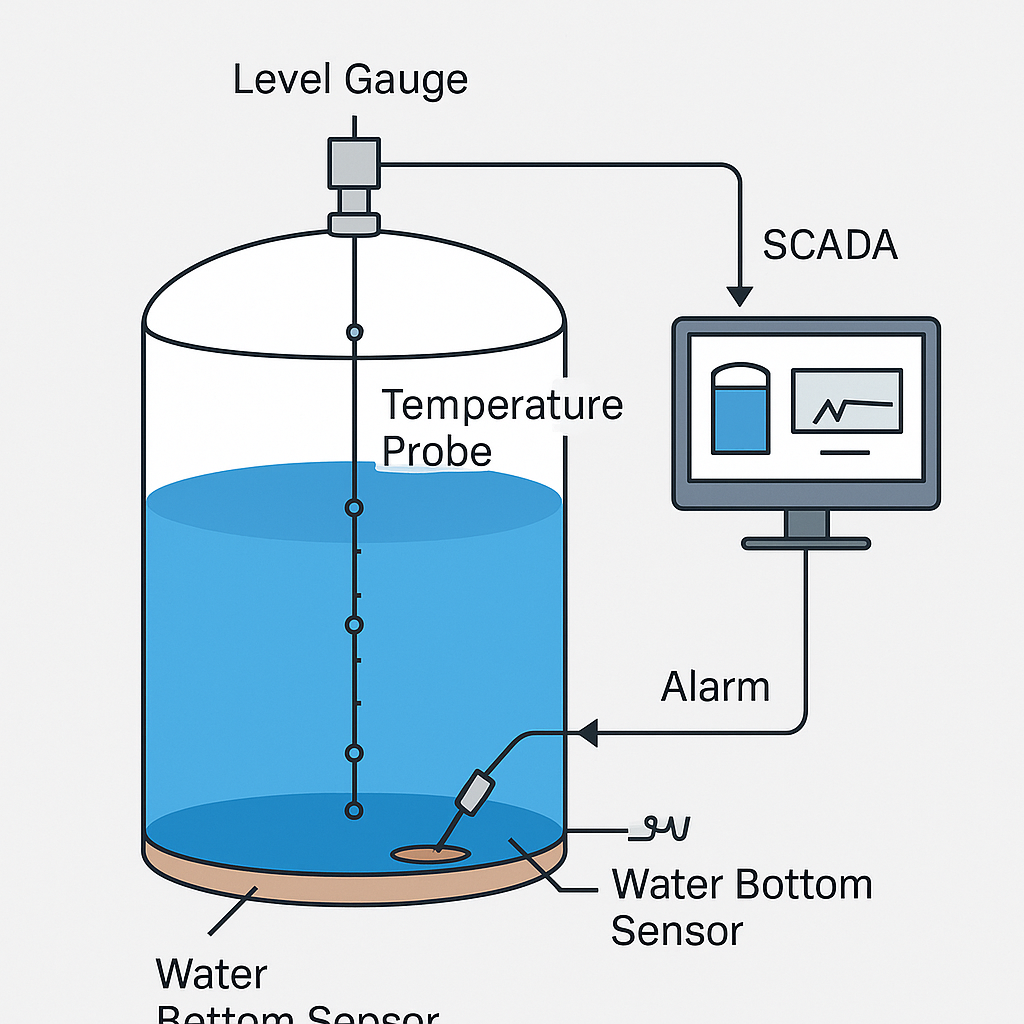

3. Environmental Conditions

Small-diameter storage tanks often face challenging environments. Factors like temperature fluctuations, pressure variations, and the presence of vapors or foam can affect measurement accuracy. Choosing a level transmitter with the right environmental tolerance is crucial.

Temperature and Pressure: Make sure the level transmitter can operate within the temperature and pressure ranges of your tank. Radar level transmitters are particularly well-suited for extreme conditions.

Vapor or Foam Presence: If your tank contains liquids that produce vapors or foam, consider a radar-based level transmitter, which is not affected by these factors.

4. Accuracy and Precision Requirements

Level transmitters come in various accuracy levels, and it is essential to match the accuracy to your application needs. For example, if the tank is used for chemical storage and precise measurements are critical, a radar level transmitter will offer the high accuracy required. In contrast, for less critical applications, a float or ultrasonic level transmitter may suffice.

High Precision: Radar or Guided Wave Radar (GWR) transmitters are best for applications requiring high accuracy.

Standard Precision: For less demanding applications, float-based or ultrasonic level transmitters can provide sufficient accuracy at a lower cost.

5. Explosion-Proof Requirements

For tanks storing flammable or explosive liquids, it is essential to choose an explosion-proof level transmitter. Most radar and ultrasonic level transmitters can be fitted with explosion-proof certifications (e.g., ATEX, IECEx), ensuring safe operation in hazardous environments.

6. Installation and Maintenance

When dealing with small-diameter tanks, installation space can be limited. Choosing a level transmitter that fits within the available space is important. Furthermore, consider the ease of maintenance and cleaning. Non-contact systems like radar or ultrasonic transmitters often require less maintenance than mechanical systems like float-based transmitters.

7. Cost Considerations

Budget constraints are always a factor in equipment selection. While radar and GWR transmitters offer high performance, they come with a higher initial cost. If precision is less critical, ultrasonic or float-based transmitters may offer a more budget-friendly solution. However, remember that the long-term benefits of high-accuracy systems may justify the initial investment.

Conclusion

Choosing the right level transmitter for small-diameter storage tanks involves evaluating various factors such as the type of liquid, environmental conditions, accuracy needs, and cost.

For high accuracy and harsh conditions, radar level transmitters or Guided Wave Radar (GWR) are the best options.

For more budget-conscious applications, ultrasonic or float-based transmitters are suitable for simpler setups.

Considerations like temperature, pressure, and potential explosion risks should always guide your decision to ensure safety and performance.

By understanding these key factors, you can select a level transmitter that meets your operational needs, ensuring reliable and accurate level measurement for small-diameter storage tanks.