1. What Is Continuous Level Measurement?

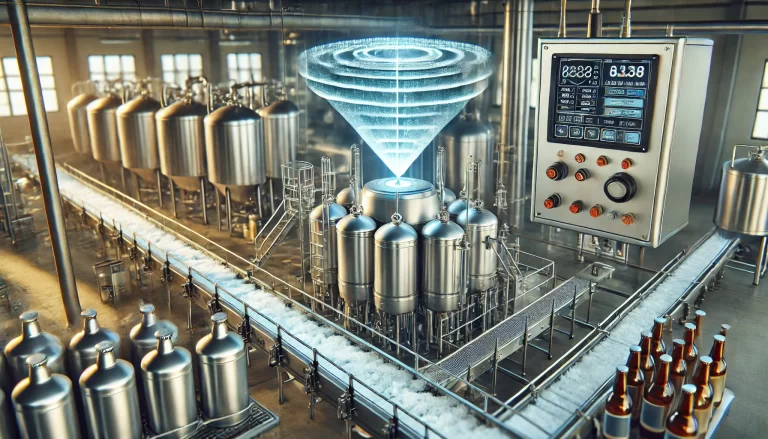

Continuous level measurement is the process of real-time monitoring of the level of liquids, powders, or bulk solids in tanks, vessels, or silos. Unlike point level measurement—which only detects high or low level thresholds—continuous level sensors provide precise readings throughout the full measurement range.

Industries such as chemical processing, food and beverage, water treatment, and manufacturing rely heavily on continuous level measurement to:

Prevent material shortages or overfills,

Optimize resource use,

Automate processes,

And ensure operational safety.

2. Overview of Continuous Level Measurement Technologies

Level transmitters convert the height of a material inside a container into electronic signals. These signals can be displayed locally or integrated into control systems like SCADA or DCS.

The selection of the right sensing technology is crucial for accurate and reliable measurement. Commonly used types include:

Radar level transmitters

Ultrasonic level transmitters

Magnetic level gauges

Each offers unique advantages based on the application environment, material type, and process requirements.

3. How to Choose the Right Technology? A Closer Look at Three Solutions

✅ 1. Radar Level Transmitters – High-Precision with Adaptive Technology

Recommended for: Liquids, powders, and solids in process tanks or silos

Radar level transmitters use electromagnetic waves to measure material levels non-contact, making them ideal for challenging environments.

The Jiwei radar level transmitter offers:

±1mm accuracy, even in dynamic conditions

Adaptive technology that automatically adjusts to handle steam, dust, foam, or temperature variations

Bluetooth connectivity for wireless configuration and real-time monitoring via mobile app

Wide measuring range: up to 30 meters

Non-contact design: eliminates sensor wear and contamination

High durability: suitable for corrosive, high-pressure, or high-temperature processes

➡️ Use this technology if your process involves:

Viscous liquids

High-pressure tanks

Dusty environments

Applications requiring zero maintenance

✅ 2. Ultrasonic Level Transmitters – Cost-Effective & Explosion-Proof Option

Recommended for: Water, chemicals, and non-volatile liquids in open or closed tanks

Ultrasonic level transmitters measure level using high-frequency sound waves. They provide a non-invasive and budget-friendly alternative to radar.

Jiwei’s ultrasonic solution features:

Explosion-proof certification (Ex d IIC T6 Gb) for hazardous environments

RS485 communication for easy integration with industrial control systems

Remote separation design, allowing flexible mounting and simplified maintenance

Durability against condensation and dust

Economical pricing for broad industry adoption

➡️ Choose ultrasonic level transmitters if you need:

A low-cost, non-contact solution

Basic level monitoring in water or chemical tanks

Certified devices for explosive areas (e.g., fuel storage)

✅ 3. Magnetic Level Gauges – SIL2/3 Certified with Visual Indication

Recommended for: Corrosive or hazardous liquids, oil tanks, and safety-critical processes

Magnetic level gauges use a float and indicator mechanism to display liquid level and can be enhanced with electronic transmitters or switches.

Jiwei’s magnetic level gauges include:

Over 10 national patents for design innovation

SIL2/SIL3 certification for functional safety (with compatible transmitter and magnetic switch)

4-20mA + HART communication for system integration

Visual indicators for power-free local readouts

Corrosion-resistant construction for aggressive chemicals

Excellent stability and accuracy over long-term use

➡️ Ideal for:

Safety-focused applications

Storage of flammable or corrosive liquids

Systems requiring both visual and digital output

✅ 4. Comparison Table of Technologies

| Technology | Accuracy | Communication | Key Features | Ideal Use Case |

|---|---|---|---|---|

| Radar | ±1mm | Bluetooth | Adaptive, high-range, harsh environments | Powders, hot liquids, silos |

| Ultrasonic | ±5mm | RS485 | Explosion-proof, affordable | Water tanks, non-foamy liquids |

| Magnetic Level Gauge | ±5mm | 4-20mA + HART | SIL2/3 certified, local visual reading | Corrosive chemicals, safety systems |

5. Why Continuous Level Measurement Matters

Accurate and real-time level monitoring plays a vital role in:

✅ Process Optimization: Ensures consistent material flow and reduces downtime

✅ Inventory Control: Prevents stockouts or overflow, aiding production planning

✅ Safety & Compliance: Minimizes the risk of spills, overpressure, or equipment failure

✅ Energy Efficiency: Reduces waste and unnecessary resource use

✅ Regulatory Compliance: Meets industry-specific safety and operational standards

6. Final Thoughts: Making the Smart Choice

Selecting the right level measurement technology depends on your application’s material type, environmental conditions, and safety needs.

Whether you require:

High-precision radar for dusty silos,

Cost-effective ultrasonic for clean water tanks,

Or SIL-certified magnetic gauges for hazardous chemicals—

Jiwei provides tailored, cutting-edge solutions that combine performance, safety, and cost-effectiveness.

Invest in the right level transmitter to:

Boost process reliability

Reduce downtime

And ensure compliance with industry standards