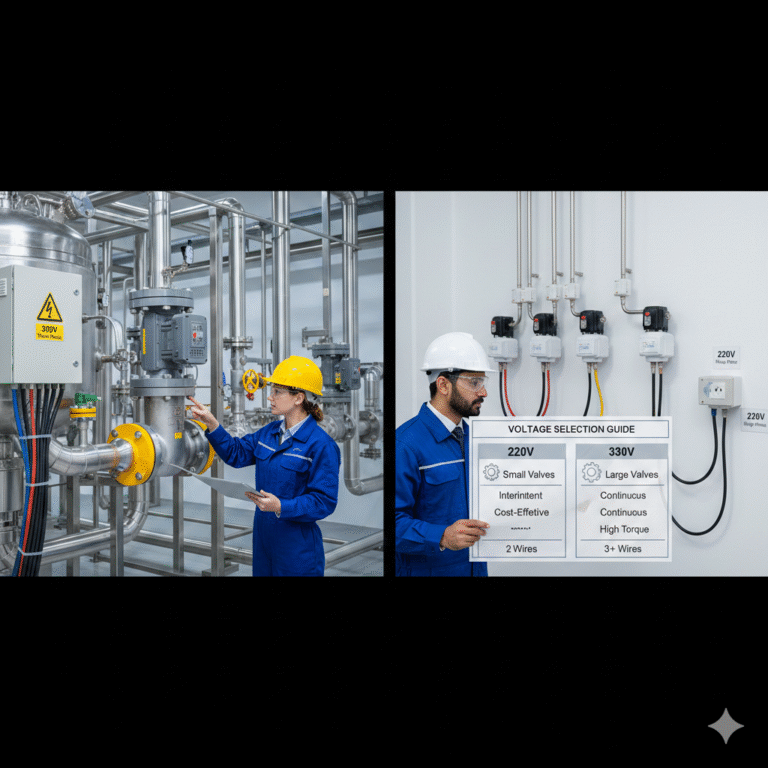

In chemical plants and automated control systems, selecting the correct drive voltage (220V single-phase vs. 380V three-phase) for electric valves directly impacts the stability of the equipment, energy consumption, and maintenance costs. This article explores how to determine the appropriate voltage based on key selection criteria and highlights the core advantages of each voltage level, with practical insights for industrial applications.

How to Decide Whether to Choose 220V or 380V for Electric Valves?

Key Criteria for Selection (Focusing on Chemical Industry Applications)

Practical Selection Steps (for on-site use in chemical plants):

Calculate Torque/Force Requirements: Based on the valve type (on/off or modulating), size, and medium pressure, calculate the required torque or force (refer to valve manufacturer data tables for comparison).

Assess Power Supply Availability: Check the local power distribution system (is there a three-phase 380V outlet?) and cable distance (if more than 50 meters, opt for 380V to minimize voltage drop).

Consider Operational Mode: For continuous operation, high-frequency start-stop, or high-torque scenarios, select 380V; for intermittent operation, small sizes, or distributed control points, choose 220V.

Quick Reference for Chemical Plant Selection:

Large sizes (≥DN65), high torque/force, continuous operation (24/7) → Choose 380V.

Small sizes (≤DN50), low torque/force, intermittent use, limited power supply (only single-phase) → Choose 220V.

Core Advantages of 220V and 380V Electric Valves

220V Single-Phase Electric Valves: Flexibility and Convenience for Distributed Applications

Adaptability to Power Supply: No need for a three-phase power source, making it ideal for distributed control points or small auxiliary devices (e.g., sampling or vent valves) in chemical plants. This reduces the need for extensive power distribution upgrades.

Simple Installation and Maintenance: Wiring requires only two wires (live and neutral), making it easier for field engineers to commission and troubleshoot (e.g., short circuits or loose connections).

Cost-Effective: The motor structure is simple (single-phase induction motor), and components such as controllers and contactors are lower in cost, making it suitable for small valves (e.g., DN15-DN50 ball valves).

Low Power Consumption: For intermittent operation, these valves have low idle losses and do not require additional equipment for voltage reduction, providing excellent energy efficiency (e.g., for laboratory reactors).

380V Three-Phase Electric Valves: Stability and Heavy Load Support for Critical Processes

Powerful Performance: Three-phase induction motors provide high torque and starting torque, making them suitable for large-diameter (DN65-DN300), high-resistance valves (e.g., high-pressure stop valves, viscous medium modulating valves). They meet the high torque demands of core chemical processes.

High Operational Stability: With balanced three-phase current, the motor generates less heat and vibration, ensuring stable, long-term operation (e.g., 24-hour continuous loops) without overload risks.

Resistance to Interference and Low Losses: Stable three-phase voltage minimizes interference from variable frequency drives, motors, and other sources. Voltage drop is minimal (with the same cable gauge, 380V transmission distance is 1.7 times that of 220V), making it ideal for long-distance control (e.g., over 50 meters between plant area and control room).

Heavy Load Adaptability: 380V valves can be equipped with soft starters, autotransformer starters, or variable frequency drives to handle sudden heavy load conditions (e.g., sticky media or jammed valves in chemical waste pipes), extending the life of the equipment.

Key Considerations When Choosing Electric Valves for Chemical Applications

Explosion-Proof Areas: In hazardous locations (e.g., Ex d IIBT4 zones), whether using 220V or 380V, explosion-proof rated actuators are required. Wiring must also meet explosion-proof standards (e.g., use of explosion-proof conduit and sealed fittings).

Control Circuit Compatibility: 220V electric valves can be directly controlled with standard relays, while 380V valves require three-phase contactors and overload protection devices. Engineers should ensure that appropriate interfaces are reserved in the control system design.

Conclusion

220V Electric Valves: These offer flexibility and cost-effectiveness, making them suitable for distributed, low-power, and intermittent applications in chemical plants. They reduce initial investment and operational costs.

380V Electric Valves: These provide stability and support for heavy loads, powering critical, large-diameter, continuous valves in key chemical processes. They ensure reliable long-term operation.

The core of the selection process is matching the demand. Start by evaluating valve torque/force, operational mode, and power supply conditions, then consider the safety and stability requirements of the chemical plant. This will guide you to a precise voltage choice. For specific valve applications (e.g., modulating valves or shut-off valves), further details can be provided for tailored selection scenarios.