Relays are essential components in electrical circuits, often used for switching and control applications. Understanding how to choose between normally open (NO) and normally closed (NC) relay contacts is critical to ensure the proper operation and safety of your circuit. This guide provides a detailed overview of their functionalities, applications, and selection criteria, supported by practical examples.

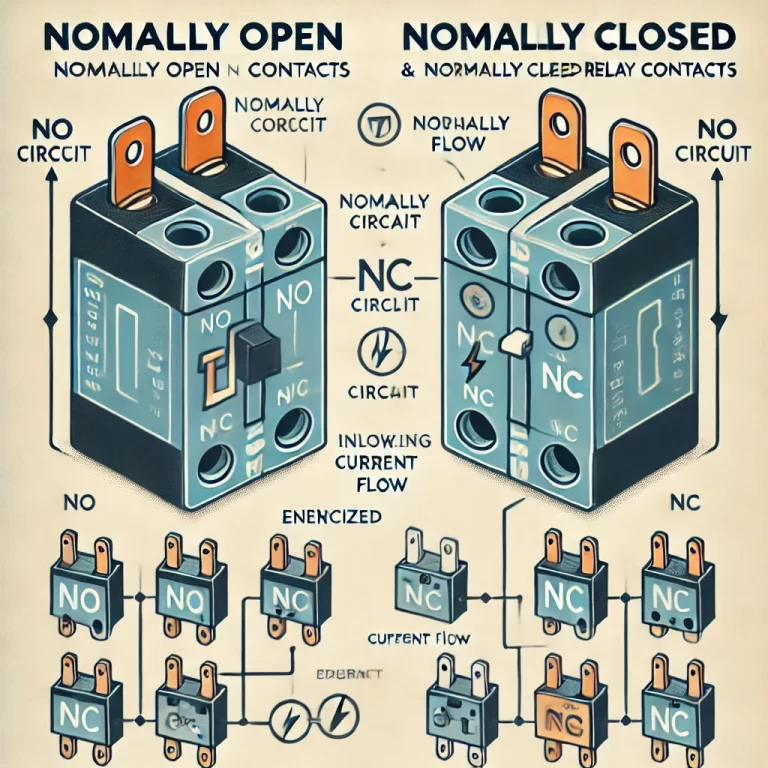

1. What Are Normally Open (NO) and Normally Closed (NC) Contacts?

Normally Open Contacts (NO):

NO contacts are open when the relay is not energized. When the relay is activated, the contacts close, allowing current to flow through the circuit.

Typical Applications:

Start Control: Often used in circuits where the load needs to be powered on when the relay is energized, such as starting motors, turning on lights, or initiating heating systems.

Switch Control: Suitable for circuits that require switching loads when the relay operates.

Examples:

Motor Start: The NO contact closes when the relay is energized, enabling the motor to start.

Lighting Control: The NO contact activates a light when the relay is energized.

Normally Closed Contacts (NC):

NC contacts are closed when the relay is not energized. When the relay is activated, the contacts open, interrupting the current flow in the circuit.

Typical Applications:

Stop Control: Ideal for stopping devices or disconnecting circuits when the relay is energized.

Protective Circuits: Commonly used to prevent equipment from operating under abnormal conditions, ensuring safety and protection.

Examples:

Safety Shutoff: An NC contact disconnects power to a motor during a fault condition.

Temperature Control: An NC contact interrupts power to a heating element when the temperature exceeds a preset threshold.

2. How to Select Between NO and NC Contacts

When deciding between NO and NC contacts, consider the following factors:

2.1 Circuit Requirements:

Starting or Activating a Load: Use NO contacts for circuits that need to be activated upon relay operation.

Stopping or Interrupting a Load: Use NC contacts for circuits that need to be deactivated upon relay operation.

2.2 Safety Considerations:

NC contacts are often preferred in safety-critical applications to ensure the circuit is closed (operational) by default and only opens when necessary to interrupt power.

2.3 Logical Operations:

In complex systems, both NO and NC contacts can be used in tandem to achieve specific control logic, such as simultaneously starting one device while stopping another.

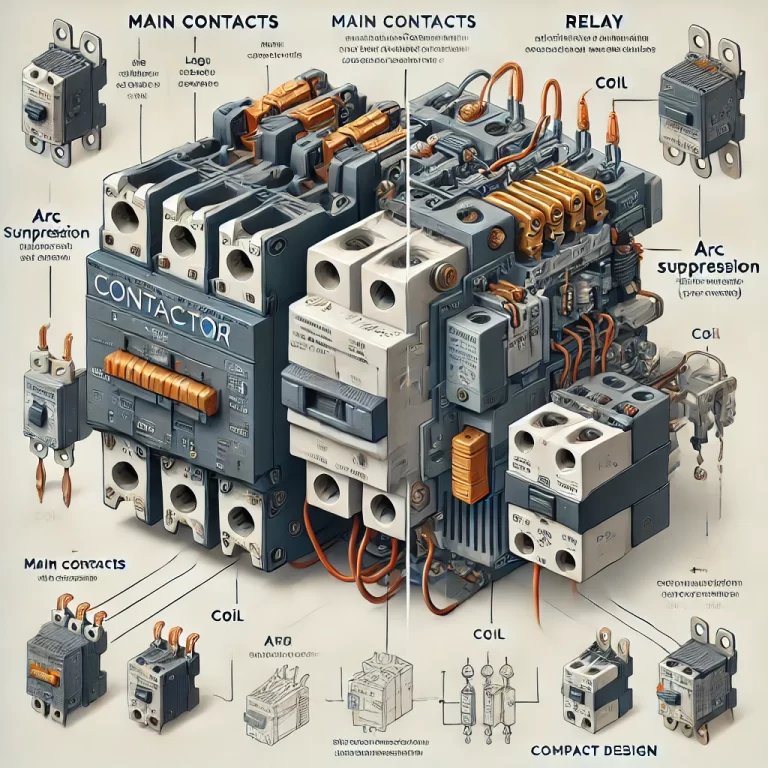

3. Factors to Consider When Choosing a Relay

Beyond the type of contacts, selecting the appropriate relay requires evaluating several parameters:

3.1 Contact Ratings:

Ensure the relay’s contacts can handle the voltage and current requirements of your circuit. Overloading contacts can cause premature wear or failure.

3.2 Number of Contacts:

Choose a relay with sufficient contacts (single-pole, double-pole, or more) to meet your circuit design needs.

3.3 Control Voltage and Current:

Verify that the relay’s coil voltage and current match your control circuit specifications.

3.4 Durability and Lifespan:

Consider the relay’s mechanical and electrical lifespan, especially for high-frequency switching applications.

3.5 Environmental Conditions:

Account for factors such as temperature, humidity, and vibration, which may affect relay performance.

4. Common Contact Configurations and Applications

Modern relays often feature multiple contact configurations to cater to various needs:

NO + NC Combination Contacts: Provide versatility by enabling both connection and disconnection functionalities within the same relay.

Example: Energizing the relay closes the NO contact to power a device while opening the NC contact to disconnect another circuit.

Multi-Circuit Relays: Allow simultaneous control of multiple loads, useful in automation and industrial control systems.

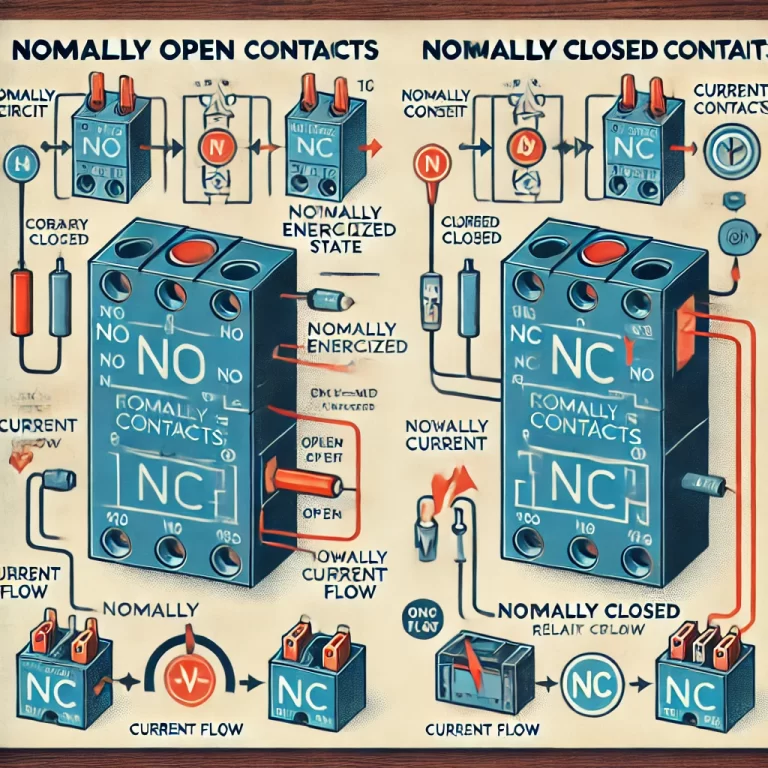

5. Visualizing NO and NC Contacts

For clarity, consider the following scenarios:

NO Contact Operation:

Initial State (Relay De-Energized): Contact is open; no current flows.

Active State (Relay Energized): Contact closes; current flows through the load.

NC Contact Operation:

Initial State (Relay De-Energized): Contact is closed; current flows.

Active State (Relay Energized): Contact opens; current flow is interrupted.

Adding diagrams or circuit illustrations here would enhance understanding and visualization.

Summary

NO Contacts: Used for applications requiring circuit activation when the relay operates.

NC Contacts: Used for applications requiring circuit interruption when the relay operates.

When selecting relay contacts, always align with the circuit’s operational needs, safety considerations, and environmental factors. Additionally, consider relay parameters such as contact ratings and control specifications to ensure reliable performance and longevity.

Choosing the right relay contact type ensures both functional efficiency and safety in your electrical systems.