In the process of selecting a frequency converter, the concepts of light load and heavy load are crucial. Proper understanding and distinction between these two load types are essential for choosing the right frequency converter.

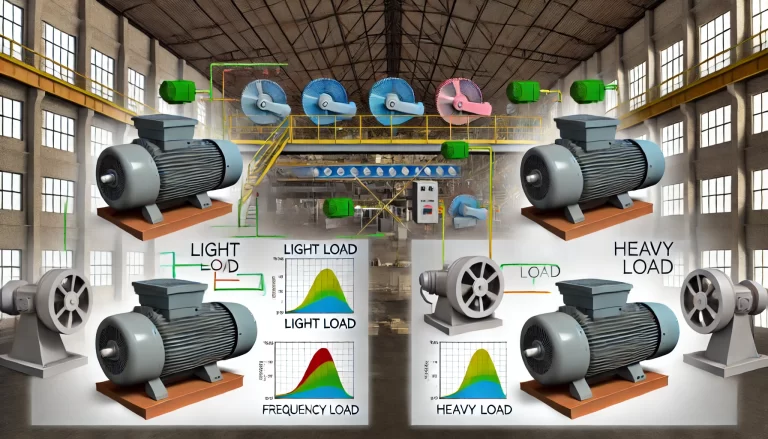

What is Light Load?

In the electrical industry, light load refers to a situation where the electrical control components, under rated power conditions, can drive loads of the same power but with relatively lower output torque. Typical light load equipment includes centrifugal fans, water pumps, and oil pumps. The load characteristics of these devices are often proportional to the square of the speed, meaning that the load torque (T) is proportional to the square of the speed (n^2).

Characteristics of Light Load Equipment:

- The load torque increases rapidly as the speed increases.

- At low speeds, the load torque is relatively small.

- Suitable for frequency converters with light load (LO) power ratings.

- The frequency converter’s operating current is small.

Selection Recommendation:

For light load equipment, when selecting a frequency converter, ensure that the light load power of the converter is not lower than the rated power of the motor. Light load equipment typically requires lower overload capacity.

What is Heavy Load?

Heavy load refers to equipment whose load characteristics remain relatively constant or exhibit minimal change. Typical heavy load equipment includes conveyors, mixers, extruders, cranes, hoists, air compressors, Roots blowers, ball mills, injection molding machines, and reciprocating plunger pumps. The load characteristics of these devices are usually independent of speed, meaning that the load torque (T) remains essentially constant.

Characteristics of Heavy Load Equipment:

- The load torque remains constant throughout the operation.

- Requires high starting torque.

- Suitable for frequency converters with heavy load (HO) power ratings.

- The operating current of the frequency converter is larger.

Selection Recommendation:

For heavy load equipment, ensure that the heavy load power rating of the frequency converter is not lower than the motor’s rated power. Heavy load equipment generally requires a higher overload capacity, which may result in higher temperatures. Thus, it is also essential to consider frequency converters that can handle higher operating temperatures.

General Guidelines for Load Classification:

In general, the relative ranges for no-load, light load, heavy load, full load, and overload can be categorized as follows:

- No-load: 0%

- Light load: below 30%

- Heavy load: 80%-100%

- Full load: 100%

- Overload: above 100%

Example of Frequency Converter Selection:

Problem: For a conveyor belt motor with a rated voltage of 380V, power of 5.5kW, and current of 11.6A, without overload conditions, how should the power module be selected?

Solution: A conveyor belt is classified as a constant torque load. Therefore, the frequency converter should be selected based on the heavy load (HO) power rating. According to the D31.3 catalog, the power module model 6SL3210-1PE21-8UL0 (without integrated filter) PM240-2 can be chosen to drive this motor.

Conclusion:

In the selection of frequency converters, properly distinguishing between light load and heavy load is key to ensuring the normal operation of the equipment. Light load equipment such as centrifugal fans and water pumps should opt for frequency converters with light load power ratings, while heavy load equipment like conveyor belts and mixers should select converters with heavy load power ratings. By making appropriate selections, equipment efficiency and reliability can be improved.