When it comes to selecting the right temperature measurement device for marine applications, both bimetallic thermometers and pressure thermometers are commonly used. However, their operating environments and advantages differ slightly, and understanding these differences can help you make the best choice for your specific needs.

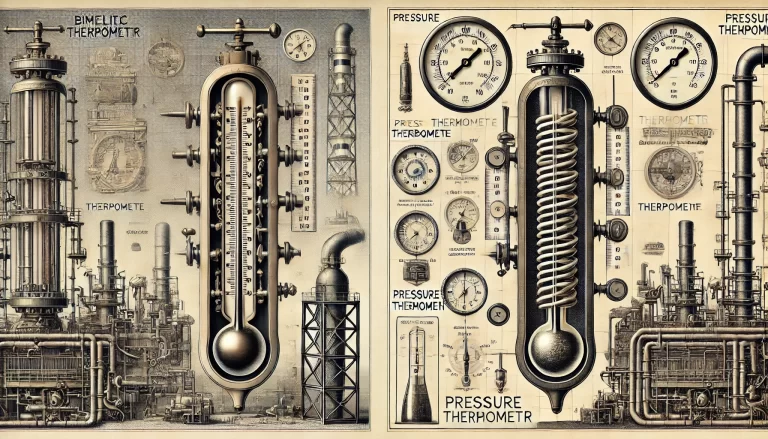

1. Bimetallic Thermometers: Operating Principle and Advantages

A bimetallic thermometer operates on the principle of the differential expansion of two metal strips with different coefficients of linear expansion. These metal strips are welded together to form a single sensing element. One end of this element is fixed, while the other end is free. When the temperature changes, the difference in expansion rates between the two metals causes the strip to bend. This bending movement is transmitted through a mechanism, typically a pointer, that moves across a calibrated scale to indicate the temperature.

Advantages of Bimetallic Thermometers:

- Wide Measurement Range: Bimetallic thermometers can measure temperatures across a broad range, often from -50°C to 500°C, making them versatile for various applications.

- Mechanical Design: With their purely mechanical design, bimetallic thermometers are reliable in environments where electronic devices may fail due to power loss or harsh conditions.

- Durability: These thermometers are known for their robustness and long service life, especially in industrial settings.

Bimetallic thermometers are ideal for use in stable environments where mechanical simplicity and reliability are crucial. They are commonly used in industries such as automotive, food processing, and HVAC systems.

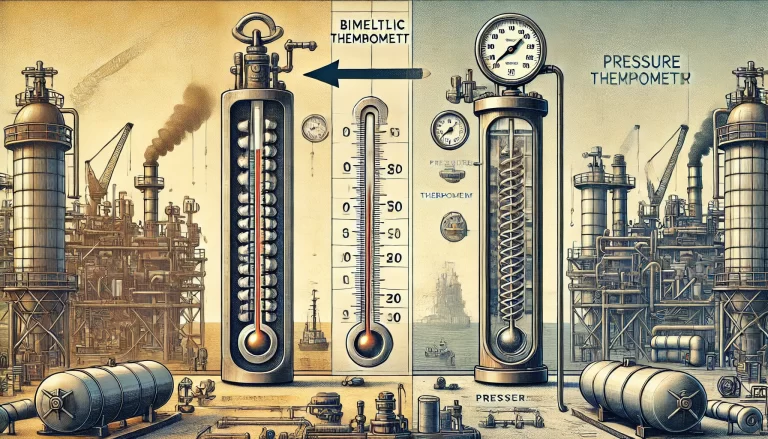

2. Pressure Thermometers: Operating Principle and Advantages

Pressure thermometers, also known as liquid or gas-filled thermometers, measure temperature based on the relationship between temperature and pressure or volume. These thermometers consist of a spring tube filled with a liquid or gas that expands as the temperature rises. The pressure exerted by the fluid causes the curvature of the spring tube to change, resulting in displacement at the free end. This displacement is transferred to a pointer via a linkage mechanism, indicating the temperature on a calibrated dial.

Advantages of Pressure Thermometers:

- Simple Operation: Pressure thermometers are easy to use and require minimal maintenance. They are often preferred for straightforward, reliable temperature monitoring in many applications.

- Remote Sensing Capabilities: One of the key benefits of pressure thermometers is the ability to remotely monitor temperature through the use of tubing, making them ideal for measuring temperature in hard-to-reach areas or hazardous environments.

- Wide Range of Applications: Pressure thermometers are often used in low-temperature measurements (typically from -20°C to 150°C) and are ideal for applications where temperature variations need to be observed over long distances.

Pressure thermometers are suitable for environments where ease of use, remote monitoring, and sensitivity to low temperatures are important factors. They are commonly found in refrigeration, water treatment plants, and oil or gas industries.

3. How to Choose the Right Thermometer for Your Needs

Choosing between a bimetallic thermometer and a pressure thermometer ultimately depends on your specific requirements and environmental factors. Here are some key considerations:

- Temperature Range: If your application requires monitoring temperatures beyond 150°C, a bimetallic thermometer may be a better choice due to its wide measurement range.

- Installation Environment: If you need a thermometer for a harsh or challenging environment where mechanical simplicity and durability are critical, the bimetallic thermometer’s robust design would be advantageous.

- Remote Monitoring: If remote temperature monitoring is required, especially for hazardous or difficult-to-access locations, a pressure thermometer with its ability to transmit readings remotely would be more appropriate.

- Precision and Sensitivity: Bimetallic thermometers tend to be more accurate in stable environments, while pressure thermometers are more suited for continuous monitoring in dynamic conditions.

Conclusion

Both bimetallic and pressure thermometers offer unique advantages depending on the application. By understanding their working principles, advantages, and limitations, you can select the most suitable temperature measurement device to meet your needs, ensuring optimal performance in your specific operational environment.