Introduction

Flow measurement is a critical aspect of many industries, including oil and gas, chemical processing, and water management. However, selecting the right flowmeter is not straightforward, as different meters react differently to various fluid properties. The physical and chemical characteristics of a fluid can significantly impact the accuracy, efficiency, and longevity of the flowmeter. Therefore, it is essential to analyze key fluid properties before selecting the appropriate measurement method and device.

This article provides a detailed guide on how various fluid properties—such as density, viscosity, temperature, pressure, chemical corrosion, and phase changes—affect flowmeter selection. Additionally, it offers practical recommendations for choosing a suitable flowmeter under different conditions.

1. Fluid Temperature and Pressure

Temperature and pressure are fundamental parameters that influence fluid behavior and, consequently, flow measurement accuracy.

Impact on Measurement Accuracy

Gas Density Variations: When measuring gases, temperature and pressure changes can significantly alter the density. If these variations are not accounted for, they may introduce large measurement errors. To correct this, temperature and pressure compensation techniques are often required.

Thermal Expansion in Liquids: Liquids typically expand when heated, which can impact flow measurements if density corrections are not applied.

Considerations for Flowmeter Selection

For high-pressure applications, select a flowmeter with robust structural integrity, such as Coriolis mass flowmeters or differential pressure meters.

For varying temperature conditions, electromagnetic or ultrasonic flowmeters with temperature compensation are ideal.

Ensure the flowmeter material can withstand extreme temperatures and pressures.

2. Fluid Density and Its Influence

Density is a crucial factor in flow measurement, particularly for gas flowmeters.

Key Considerations

Liquids: In most applications, liquid density remains relatively constant unless there are large temperature fluctuations.

Gases: Gas density is highly dependent on both temperature and pressure, requiring compensation for accurate measurement.

Recommended Flowmeters

For gases: Thermal mass flowmeters and Coriolis mass flowmeters can measure mass flow directly without requiring density compensation.

For liquids: Differential pressure flowmeters and volumetric flowmeters can be used effectively if density remains stable.

3. Viscosity and Its Effects on Flowmeters

Viscosity is a measure of a fluid’s resistance to flow. It varies significantly between different liquids and changes with temperature.

Effects on Flow Measurement

High-viscosity fluids (e.g., oils, syrups) create resistance, affecting the flowmeter’s accuracy.

Low-viscosity gases generally have minimal impact on measurement.

Recommended Flowmeters

Coriolis flowmeters: Unaffected by viscosity, making them ideal for measuring fluids with varying viscosity.

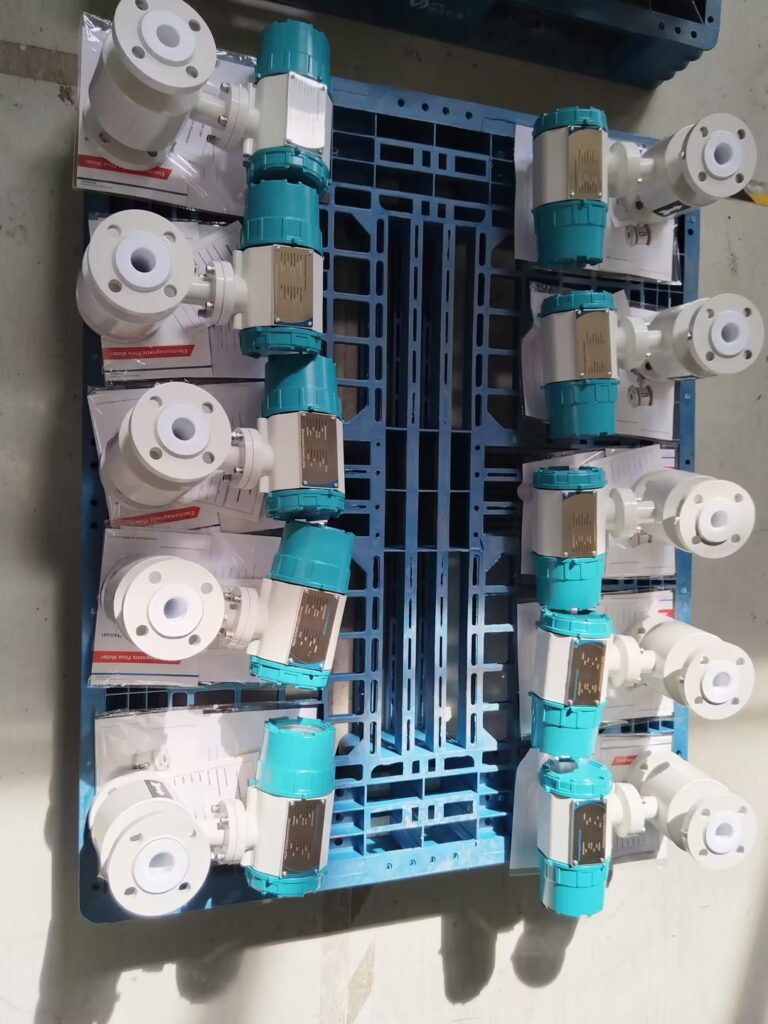

Electromagnetic flowmeters: Work well for conductive liquids with different viscosities.

Positive displacement meters: Suitable for highly viscous fluids, as their measurement is independent of flow profile changes.

4. Chemical Corrosion and Scaling

Certain fluids are highly corrosive or tend to form deposits, which can significantly impact flowmeter performance and longevity.

Challenges

Chemical Corrosion: Strong acids, alkalis, and aggressive chemicals can damage flowmeter components.

Scaling and Deposits: Some fluids (e.g., hard water) form scale or precipitate, reducing flowmeter accuracy.

Recommended Solutions

Ultrasonic flowmeters: Non-intrusive measurement prevents corrosion issues.

Electromagnetic flowmeters: Use corrosion-resistant liners (e.g., PTFE, ceramic) to handle aggressive fluids.

Special material coatings: Use corrosion-resistant alloys such as Hastelloy or titanium for extreme environments.

5. Phase Change and Multiphase Fluids

Some fluids undergo phase changes or contain multiple phases (e.g., liquid-gas mixtures, slurries), which complicate flow measurement.

Impact on Flowmeters

Gas bubbles in liquid: Can cause errors in ultrasonic or electromagnetic flowmeters.

Solid particles in liquid: May clog sensitive flowmeters like turbine meters.

Condensation in gases: Alters density and can affect measurement accuracy.

Recommended Flowmeters

Coriolis flowmeters: Effective for multiphase fluids, including slurries and liquid-gas mixtures.

Differential pressure meters: Work well in steam measurement where phase changes occur.

Vortex flowmeters: Can handle some multiphase flows but may require compensation.

Conclusion

Selecting the right flowmeter requires careful consideration of the fluid’s properties, including temperature, pressure, density, viscosity, corrosion potential, and phase behavior. The table below summarizes key recommendations:

| Fluid Property | Recommended Flowmeters |

|---|---|

| High temperature & pressure | Coriolis, differential pressure |

| Gas density variations | Thermal mass, Coriolis |

| High viscosity | Positive displacement, Coriolis |

| Chemical corrosion | Ultrasonic, electromagnetic (with resistant liner) |

| Scaling & deposits | Ultrasonic, electromagnetic |

| Multiphase fluids | Coriolis, vortex, differential pressure |

By analyzing these factors, industries can select the most suitable flowmeter for accurate and efficient fluid measurement, ultimately improving process control and reducing operational costs.