A vortex flowmeter installs one or more non-streamline bluff bodies in the fluid. The fluid alternately separates and releases two series of regular vortices on both sides of the bluff body.

This vortex is called a Karman vortex street. Within a certain flow range , the vortex separation frequency is proportional to the average flow velocity in the pipeline.

Various forms of detection components are used to measure the vortex frequency, and the fluid flow rate can be calculated.

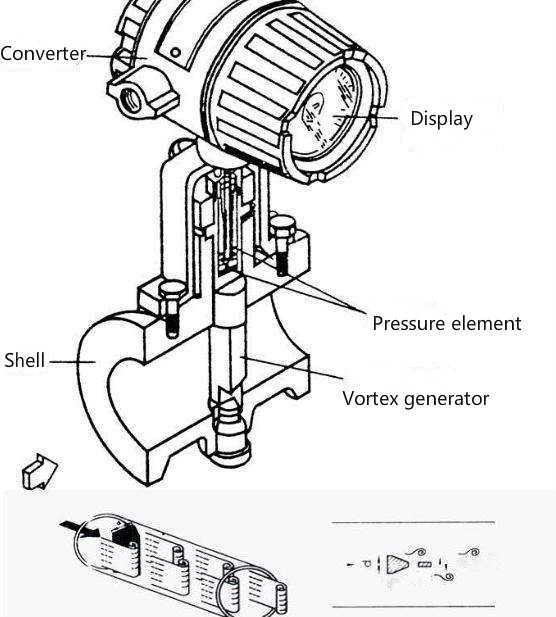

The vortex flowmeter consists of a sensor and a converter. The sensor consists of a bluff body (ie, a vortex generator), a detection element, a housing, etc.; the converter consists of a preamplifier, a filter shaping circuit, a D/A converter, and an output It is composed of interface circuits, etc.

In addition to the basic circuit, the intelligent type also combines functional modules such as microprocessor, display, HART communication, etc. in the converter.

Flow meters have their own advantages, and the purpose of selection is to choose the most suitable meter among many varieties. To correctly select flow measurement methods and instruments, you must be familiar with the measured object:

1. What type of fluid is being measured?

(1) Is the measured fluid a liquid, a gas, a steam, a liquid-liquid mixture, or a liquid-gas mixture?

(2) Is the fluid being measured clean or dirty?

(3) Does it contain moist airflow or slurry?

(4) Is the fluid being tested corrosive?

(5) Is it conductive?

2. What are the working conditions of the process? What are the limits for temperature and pressure?

(1) High temperature or low temperature?

(2) Small traffic or large traffic?

(3) Is there pulsating flow?

3. What are the installation conditions of the flow meter?

(1) Will the planned flow measurement be on an open channel or in a closed pipe?

(2) What is the inner diameter of the pipe?

(3) What is the pipe Reynolds number of the fluid under working conditions?

(4) How long are the straight pipe sections upstream and downstream of the flow meter planned to be installed? What kind of spoiler is upstream of it?

(5) Is it necessary/can I use a flow regulator?

(6) Is there excessive vibration in the process pipeline?

(7) Is the flow of fluid steady/steady? Or pulsating?

(8) What are the ambient or indoor temperature and humidity conditions?

4. What are the general requirements for flowmeter performance and flow measurement capabilities?

(1) What is the required overall accuracy? Within what flow measurement range is it required to ensure the above total accuracy?

(2) Is the flow meter used at a specific flow rate? Or is it used within a flow range?

(3) Is the flow meter used only for flow control? For flow control purposes only, what is the necessary response frequency?

(4) What is the range of the measured flow rate? What are the maximum and minimum flow values that may be encountered by chance?

After understanding the measured object clearly, select the appropriate flow measurement method and instrument according to the process conditions, mainly based on instrument performance, fluid characteristics, installation conditions, environmental conditions and life cycle cost factors.

Generally, vortex flowmeters are mainly used for flow measurement of industrial pipeline media fluids, such as gas, liquid, steam and other media. So how to judge the performance of vortex flowmeter?

It can be reflected through several important indicators such as its accuracy, reproducibility, sensitivity, and response time.

1. Accuracy

Accuracy, also known as precision, refers to how accurately the measurement results of a vortex flowmeter are close to the true value. Generally expressed as absolute error or relative error:

Absolute error = measured value – true value Relative error = absolute error / true value

Any type of flowmeter cannot measure the true value of the measured parameter absolutely accurately during measurement. It can only try to make the measured value close to the true value.

In practical applications, we generally use the indicated value of a standard instrument with higher accuracy as the true value of the measured medium, and the difference between the indicated value of the measuring flow meter and the indicated value of the standard instrument is the measurement error.

The smaller the error value, the higher the reliability of the measuring flow meter.

2. Repeatability

Repeatability refers to the difference between each measured value and the average value relative to the maximum scale range when the same vortex flowmeter is used to perform multiple repeated measurements under the condition that the measurement conditions such as pipe diameter, medium flow rate, temperature, and pressure remain unchanged. percentage.

This is an important indicator reflecting the stability of the vortex flowmeter, and generally needs to be inspected when the instrument is put into operation and daily calibration.

3. Sensitivity

Sensitivity refers to the sensitivity of the vortex flowmeter measurement. It is commonly used in the industry to express the ratio of the changes in the output of the vortex flowmeter to the changes in the measured parameters that cause these changes.

We know that an integrated vortex flowmeter with temperature and pressure compensation function can measure temperature, pressure, and flow at the same time.

The sensitivity of multiple parameters often makes it easier to reflect the performance of the flowmeter.

4. Response time

When the parameters of the measured medium change, the displayed value of the vortex flowmeter will always be accurately expressed after a period of time.

The lag time between this period and the change of the measured parameter is the reaction time of the vortex flowmeter.

In fact, other instruments also have response times. Some are expressed by time constants, such as thermal resistors for temperature measurement, and some are expressed by damping time, such as ammeters for resistance measurement, etc.