Choosing the right vortex flowmeter for your specific application requires consideration of various factors, such as the medium being measured, flow rate range, and installation conditions. Vortex flowmeters are versatile and can be used to measure gas, liquid, and steam. However, certain conditions and media types may not be ideal for vortex flowmeter usage.

1. Measured Medium

Vortex flowmeters are commonly used for gas, liquid, and steam measurements. However, the following types of media are unsuitable for vortex flowmeters:

- Fluids containing large amounts of solid particles or suspended matter.

- Media with high dynamic viscosity, such as heavy oils like residual oil.

For steam, it’s essential to specify whether it’s saturated or superheated steam, as this impacts the measurement method.

2. Flow Rate Range

When selecting a vortex flowmeter, the flow rate should be within the meter’s measurable range, preferably in the mid-to-upper part of that range:

- At lower flow rates, measurement accuracy can be affected by pipe vibrations, so it’s best to avoid measurements near the lower limit.

- If the flow range exceeds the meter’s capacity, you can adjust by reducing or enlarging the pipe diameter. However, note:

- Excessive reduction can increase flow velocity, resistance, and back pressure, while enlargement may cause cavitation.

- Use a “conical reducer + straight pipe” combination where possible to ensure stable measurements.

- Always consider whether the Reynolds number falls within a normal range.

Vortex flowmeters are not suitable for pulsating flows. If mechanical equipment like a Roots blower or a reciprocating pump is in the system, it can create pulsations that lead to measurement errors, or in extreme cases, prevent the formation of Kármán vortex streets entirely.

3. Pipe Diameter

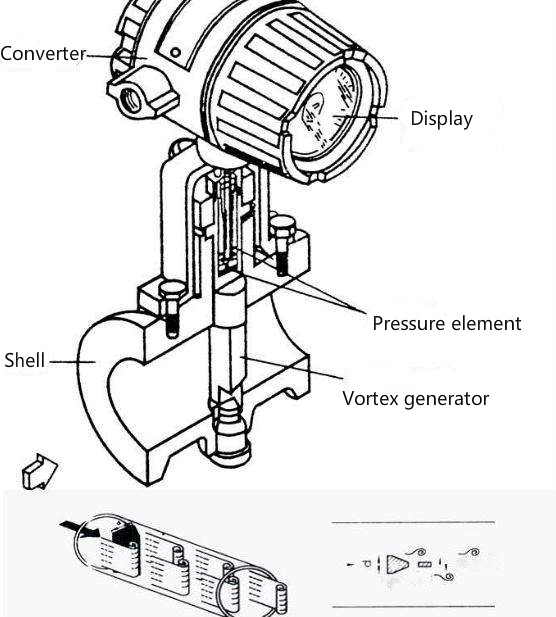

Vortex flowmeters can be installed in two ways: inline (pipe-type) or insertion-type:

- Inline flowmeters are available for pipe diameters from DN15 to DN300.

- For larger diameters, insertion-type flowmeters are available, with typical ranges up to DN2000. Larger sizes may require custom solutions.

4. Measurement Accuracy

Accuracy is classified based on the medium being measured:

- For inline vortex flowmeters, the accuracy for liquids can reach 1.0%, and for gases, it can reach 1.5%.

- For insertion-type meters, the accuracy is generally lower, at 1.5% to 2.5%.

5. Medium Temperature

Vortex flowmeters can handle a range of temperatures, generally divided into:

- Normal temperature: -40°C to 100°C.

- Medium temperature: 100°C to 250°C.

- High temperature: 100°C to 320°C.

If the medium temperature exceeds these ranges, such as in superheated steam, consider using an orifice plate flowmeter.

6. Nominal Pressure

The nominal pressure depends on the installation method:

- Wafer-type (clamp-on) vortex meters typically support up to 2.5 MPa.

- Flange-type connections can support pressures of 1.0 MPa, 1.6 MPa, and 2.5 MPa.

- Insertion-type meters can handle pressures of 1.6 MPa, 2.5 MPa, and 4.0 MPa.

7. Power Supply

Common power supply options include:

- +12VDC for 3-wire pulse output.

- +24VDC for both 3-wire pulse output and 2-wire current output.

- 3.6V lithium battery for dual power supply.

8. Output Signal

Typical output signals include:

- Voltage frequency pulse output.

- 2-wire 4-20mA output.

- HART protocol for digital communication.

Some situations may require digital outputs, and RS485 Modbus communication is available for such applications.

9. Installation Environment

Selecting the appropriate output method depends on the usage environment:

- For compressible fluids with significant temperature or pressure variations, use vortex sensors with pulse signal transmission, pressure, and temperature compensation, along with a flow integrator.

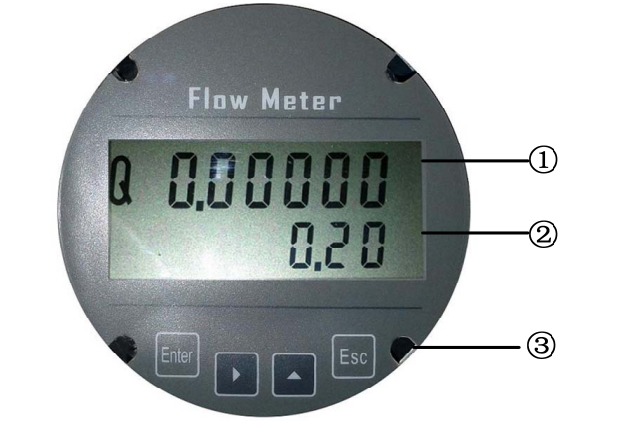

- For indoor installations with good conditions, where local reading is sufficient, a digital vortex flowmeter may suffice.

- For harsher environments or difficult-to-access installations, pulse signal output sensors with a flow integrator, or vortex transmitters with 4-20mA output, are recommended.

- In cases where local monitoring and signal transmission are both needed, use digital vortex transmitters with 4-20mA output.

- Where only signal transmission is needed, choose transmitters with 4-20mA output.

10. Protection Rating

The IP protection rating of the vortex flowmeter is important for ensuring durability in various environments:

- IP65: Protection against dust and water spray.

- IP67: Protection against dust and temporary submersion.

- IP68: Protection against dust and continuous submersion.

Selection depends on the installation environment:

- For indoor installations, IP65 is sufficient.

- For outdoor installations above ground, IP65 or higher is recommended.

- For installations in underground trenches, use IP68 with a separate amplifier to protect the equipment from rainwater.

Temperature and Pressure Compensation

The need for temperature and pressure compensation depends on the accuracy required:

- For gas measurement, both temperature and pressure compensation are necessary. Gas volume changes with temperature and pressure, so standard conditions are used for calculation.

- For superheated steam, both temperature and pressure compensation are needed since any change in either variable affects steam density and mass flow.

- For saturated steam, only one compensation (temperature or pressure) is required since there is a fixed relationship between steam density and these variables.