In industrial measurement, a wide range of conditions can be encountered, from the relatively simple to the very complex. The principle of our selection is that it must be based on the actual working conditions, so today we will look at how to choose a radar-level meter for working conditions with water vapor.

The radar level meter uses the measurement method of microwave pulses, which can be normal in the industrial frequency band range with low beam energy and can be installed in various metal and non-metal containers or pipes for non-contact continuous level measurement of liquids, slurries, and granular materials. It is suitable for dust, temperature and pressure variations, and the presence of inert gases, and vapors.

It is because of these advantages that radar level meters have become the first choice of many people for measurement, but then how to select the type has also become a problem. A user recently asked a question that caught our attention, is the case of water vapor, how to choose the type, we take a look below.

The first thing that must be understood is the temperature and pressure of the medium to be measured. Normally, the phenomenon of water vapor will only occur at higher temperatures.

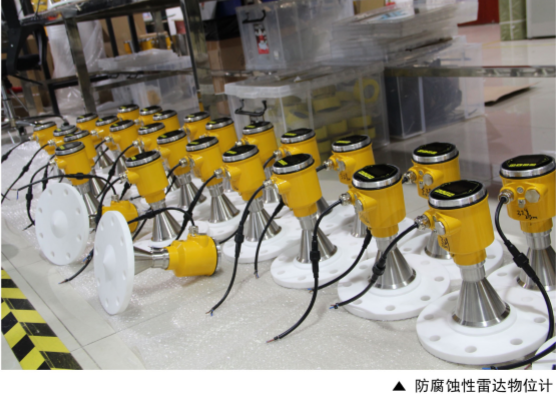

Therefore, in the choice of radar level meter, one needs to take full account of the antenna affected by temperature factors, and choose to be able to withstand the type of water vapor antenna, such as the site of corrosive liquids should also use corrosion-resistant materials.

Secondly, when the radar level meter is installed, it is also necessary to confirm whether the selected radar level meter model matches the application site selection, and only after confirming that there is no error can the installation and commissioning.

For example, in a previous case, the radar level meter had been measuring normally and accurately after installation, but soon afterward the phenomenon of dropped waves began to appear, no problem was detected, and normalcy returned after reinstallation. This was repeated several times and did not solve the problem. In theory, the steam would not interfere with the radar in any way, which is its advantage.

Through analysis, it was concluded that it was not the steam that was causing the interference, but the condensed water that was condensing on the transmitting antenna. The problem was therefore solved by replacing the antenna with a rod antenna, with the condensate flowing down the antenna, and additionally adding purging equipment would also solve the problem.

High-viscosity media is also a particularly common working condition. If the viscosity of the measured liquid is ≥ 500 cst and the liquid is strongly adherent, the waveguide tube method cannot be chosen for measurement because adhesion and crystallization will block the waveguide tube and cause false levels, in this case, the waveguide rod method can be chosen for measurement.

As for the foam measurement level, the foam caused by the feed splash or the foam mixed in the medium has no effect on the reflection of radar waves. For some media with less foam, the high-frequency radar level meter is selected, and the medium foam is selected in the media options, which can be used for a more accurate measurement of the liquid level with foam. However, the large amount of thick foam produced by violent chemical reactions will absorb and scatter radar waves, and the echo quality is very poor.

There are many types of radar level meters and many models, each with its own strengths and weaknesses, and only the best match with your own working conditions will be the best, to give maximum advantage and accurate and safe measurement.