Introduction

Even the most advanced load cells drift over time due to mechanical wear, temperature changes, or signal conditioning electronics aging. Regular calibration ensures your weighing or force measurement system remains accurate, compliant, and reliable.

In this article, we’ll walk you through the essential steps of load cell calibration, discuss common methods, and share tips for achieving the best results.

1. Why Calibrate a Load Cell?

Calibration aligns the load cell’s output with known reference standards, allowing it to provide accurate force or weight readings.

Key reasons to calibrate:

Restore measurement accuracy

Comply with legal-for-trade regulations (OIML, NIST, ISO)

Maintain process quality and product consistency

Detect sensor drift or mechanical damage early

2. Types of Calibration

| Method | Description | Typical Use |

|---|---|---|

| Static Calibration | Using known weights or forces | Weighing systems, test benches |

| Deadweight Calibration | Applying calibrated deadweights directly | High-accuracy lab setups |

| Shunt Calibration | Applying electrical shunt resistor across bridge elements | Routine checks, remote systems |

| Live Load Calibration | Using real working loads to check system performance | In-situ industrial scales |

3. Tools You’ll Need

Certified reference weights or force standards

Calibrated amplifier or signal conditioner

Data acquisition system or handheld meter

Mechanical fixtures (e.g., loading jigs, frames)

Calibration certificate templates (for documentation)

4. Step-by-Step Calibration Procedure

🔹 Step 1: Prepare the System

Power on and stabilize the load cell and electronics (allow 10–30 min warm-up)

Check for mechanical looseness, misalignment, or cable damage

🔹 Step 2: Zero the Load Cell

Ensure no load is applied

Tare or zero the reading to set a baseline

🔹 Step 3: Apply Known Weights or Forces

Apply a certified standard weight progressively (e.g., 25%, 50%, 75%, 100% of full scale)

Record the sensor output at each stage

Important: Apply and release loads slowly to avoid dynamic effects

🔹 Step 4: Plot Output vs Applied Load

Check for linearity and hysteresis

A straight, consistent line confirms good sensor health

🔹 Step 5: Adjust Calibration Coefficients

Update the slope (gain) and offset settings in your amplifier, indicator, or DAQ system

Some systems auto-calculate these from your data

🔹 Step 6: Verification

Repeat the calibration cycle to verify repeatability and accuracy

Record “as found” and “as left” results for documentation

5. Best Practices for Load Cell Calibration

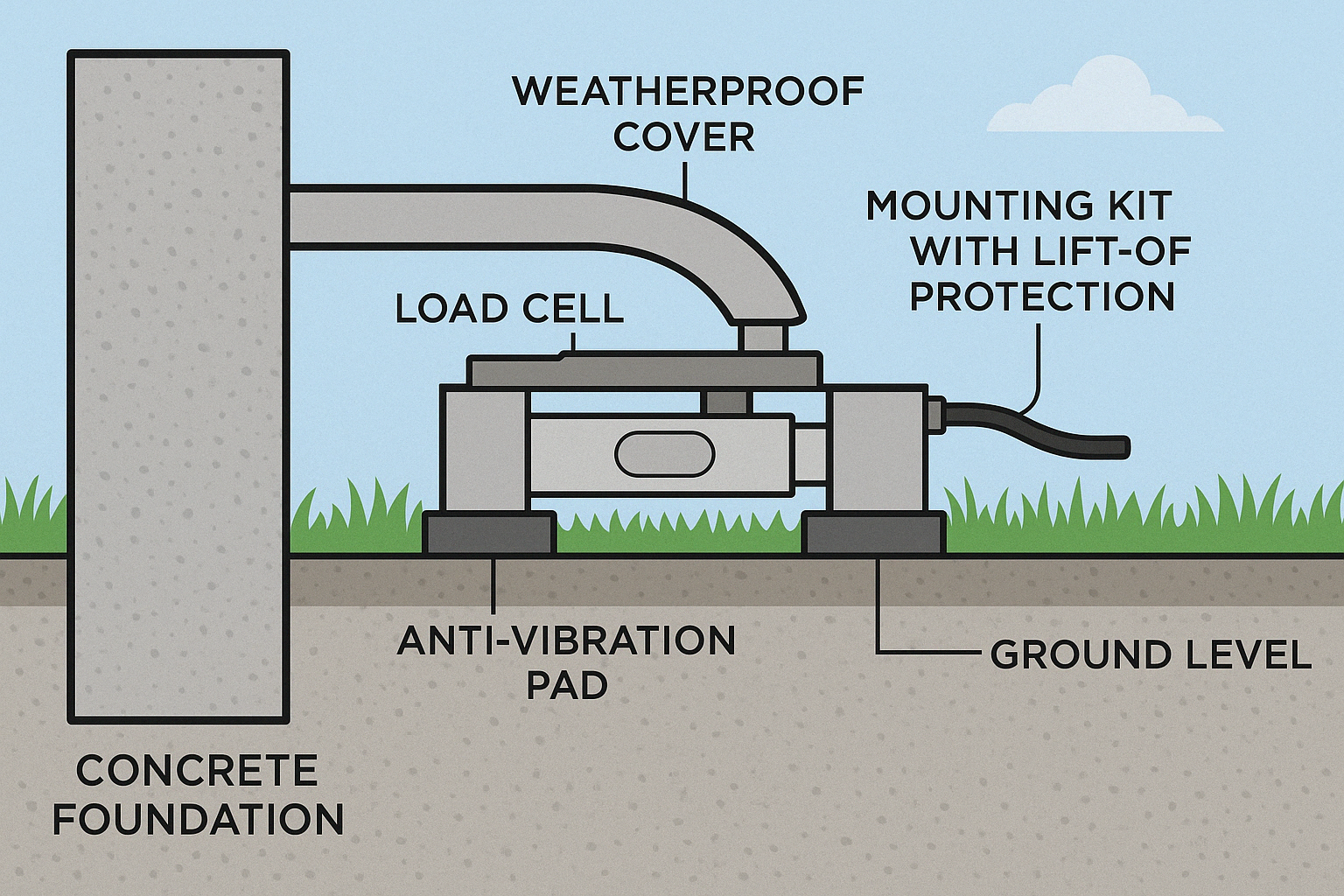

Calibrate under the same conditions as the actual operation (temperature, mounting)

Always use traceable standards (ISO 17025 calibration certificates if needed)

Avoid side loads, vibration, or thermal drift during calibration

Regularly calibrate load cells annually or after major maintenance

Maintain a detailed calibration log for each sensor

6. When Should You Recalibrate?

| Trigger Event | Calibration Action |

|---|---|

| After overload incident | Immediate recalibration |

| After mechanical shock or impact | Immediate recalibration |

| Scheduled maintenance interval (e.g., 1 year) | Routine recalibration |

| Significant temperature/environment change | Precautionary recalibration |

Conclusion

Proper calibration not only ensures accurate measurements but also extends the life of your load cell and protects the integrity of your entire process.

By following a structured, step-by-step approach and using traceable standards, you can maintain high measurement confidence—and avoid costly mistakes caused by drift or miscalibration.

Remember: Calibration is not a one-time task—it’s an ongoing commitment to quality.