Liquid fuels such as petroleum, gasoline, diesel, etc. are important energy materials, and their stability and safety during storage and transportation are crucial. Therefore, accurate measurement of liquid level in liquid fuel storage tanks becomes particularly important.

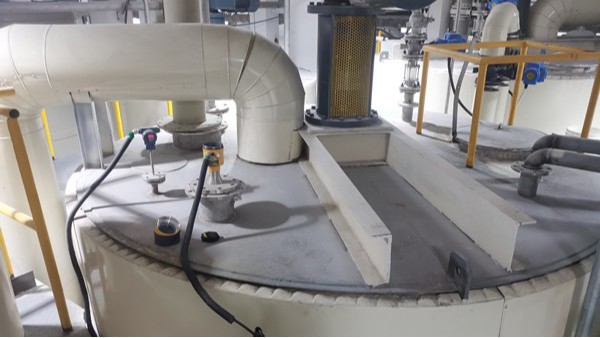

As an efficient and accurate measurement tool, the radar level gauge plays an important role in ensuring the safe storage of liquid fuel.

Liquid fuel storage tanks usually have the following characteristics: first, they are often large in size, with capacities ranging from hundreds to tens of thousands of cubic meters; second, liquid fuel has a certain degree of volatility and flammability, which requires that the measuring equipment must have good Explosion-proof performance; Finally, because liquid fuel is corrosive, the internal materials of the storage tank need to be highly corrosion-resistant.

These characteristics place special requirements on the selection and use of liquid level gauges. To better use radar level gauge for measurement, we need to understand its working principle.

The radar level gauge emits a microwave signal, which is reflected back when it contacts the liquid surface, and the liquid level is calculated based on the time difference between the echoes. This non-contact measurement method gives radar level gauges significant advantages when measuring liquid fuels.

In order to improve the use effect of the radar level gauge, the following suggestions are worth noting:

1. Choose a suitable installation location: Since liquid fuel will produce vapor, which may affect the transmission of radar waves, you should avoid installing the level gauge in a place where it is easy to accumulate. Steam location. The ideal installation position should ensure that the beam is perpendicular to the liquid surface and reduce measurement errors.

2. Consider environmental factors: Temperature, pressure, humidity and other environmental factors will affect the accuracy of the radar level gauge. It should be calibrated regularly during use to adapt to environmental changes.

3. Cleaning and maintenance: Since liquid fuel may produce sediment or condensation, these substances will adhere to the antenna part of the liquid level gauge and affect the measurement accuracy. Regular cleaning and maintenance are necessary.

4. Explosion-proof safety: When selecting a radar level meter, you must ensure that it meets the requirements of the relevant national explosion-proof standards to ensure the safety of personnel and equipment.

5. Software optimization: Modern radar level gauges are usually equipped with intelligent software that can predict and diagnose potential problems through data analysis, thereby taking measures in advance to avoid failures.

6. Train operators: Proper understanding and operation of radar level gauges is critical to ensuring accurate measurement results. Therefore, professional training for operators is an indispensable link.

Radar level gauges are ideal for liquid fuel tank level monitoring due to their high accuracy, non-contact measurement and good environmental adaptability.

Through reasonable selection, standardized installation, regular maintenance and professional operation, the accuracy and reliability of liquid level measurement can be greatly improved, providing a strong guarantee for the safe storage of liquid fuel.