In the world of industrial automation, instrumentation engineers play a central role. They are responsible for designing, maintaining, and optimizing measurement and control systems—ensuring the stable and efficient operation of complex industrial processes.

For many technicians and field personnel, becoming an instrumentation engineer is a long-term career goal. But what separates an instrumentation engineer from a general instrument technician? This article breaks down the key competencies of an instrumentation engineer into three core areas: technical skills, soft skills, and industry knowledge, and outlines common work scenarios and career development advice.

🔧 I. Technical Competencies

1. Instrumentation Knowledge

Mastery of the working principles, selection, installation, and calibration of common industrial instruments, including:

Temperature sensors (RTDs, thermocouples)

Pressure transmitters

Flow meters (electromagnetic, vortex, Coriolis)

Level sensors (radar, ultrasonic)

Analytical instruments (pH, conductivity, gas analyzers)

Familiarity with signal types and communication protocols:

4–20 mA, HART, Foundation Fieldbus, Profibus

Understanding of explosion-proof (Ex d, Ex e, Ex i) and IP (Ingress Protection) ratings.

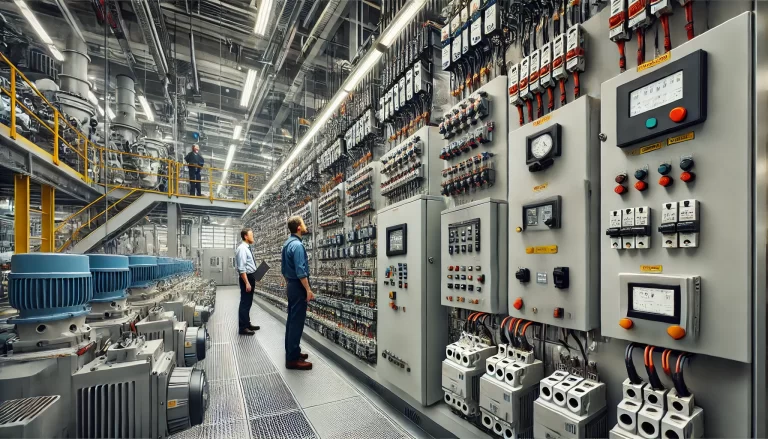

2. Automation Control Systems

Proficient in configuration and programming of:

DCS (Distributed Control Systems)

PLCs (Programmable Logic Controllers)

SCADA systems (Supervisory Control and Data Acquisition)

Knowledge of PID control loops, interlocks, advanced control strategies, and loop tuning techniques.

3. Calibration and Maintenance

Skilled in instrument calibration using tools like Fluke multifunction calibrators.

Capable of performing preventive maintenance, fault diagnostics, and spare part management.

Familiar with maintenance standards such as ISO 9001 and ISA guidelines.

4. Electrical and Functional Safety

Able to read and interpret wiring diagrams, grounding systems, and loop drawings.

Understands intrinsically safe (IS) circuits and safety instrumented systems (SIS).

Knowledge of IEC 61508 / 61511 functional safety standards.

5. Engineering Software Tools

Proficient in:

CAD software (AutoCAD, EPLAN) for instrument layout and loop drawings

Instrument management systems (SAP PM)

Process simulation software (e.g., Aspen HYSYS)

PLC/DCS programming environments (e.g., Siemens TIA Portal, DeltaV, Yokogawa CENTUM)

6. Industrial Communication and Digitalization

Understanding of industrial networking:

Modbus, Profibus, Ethernet/IP, OPC UA

Awareness of modern technologies:

IIoT (Industrial Internet of Things)

Predictive maintenance

Wireless instruments (WirelessHART)

Digital Twin models

🤝 II. Soft Skills

1. Problem Solving

Quickly identifies and resolves issues such as signal drift, device failure, or communication interruptions.

2. Communication & Teamwork

Effectively collaborates with process engineers, electricians, maintenance staff, and operators. Communicates technical issues clearly.

3. Project Management

Participates in instrumentation project planning, cost estimation, and execution during plant upgrades or shutdowns (Turnarounds).

4. Documentation

Develops and maintains detailed documents:

Instrument specifications

Standard Operating Procedures (SOPs)

Maintenance manuals

Inspection and acceptance reports

🌐 III. Industry Knowledge

1. Standards and Regulations

Familiarity with international and industry-specific standards:

ISA, IEC, API (for oil & gas), ANSI/ISA-84 (functional safety)

Understanding of local regulations such as:

GB/T (China)

ATEX (Europe)

NEC/NFPA (North America)

2. Process Understanding

Basic knowledge of process operations in industries like:

Chemicals

Oil & Gas

Pharmaceuticals

Power generation

Ability to select instruments based on process needs (e.g., reactor temperature control, flow measurement in pipelines).

3. Emerging Technologies

Tracks advancements in:

Smart instruments

Cloud-based SCADA

Wireless sensors

Digital twins and AI-based diagnostics

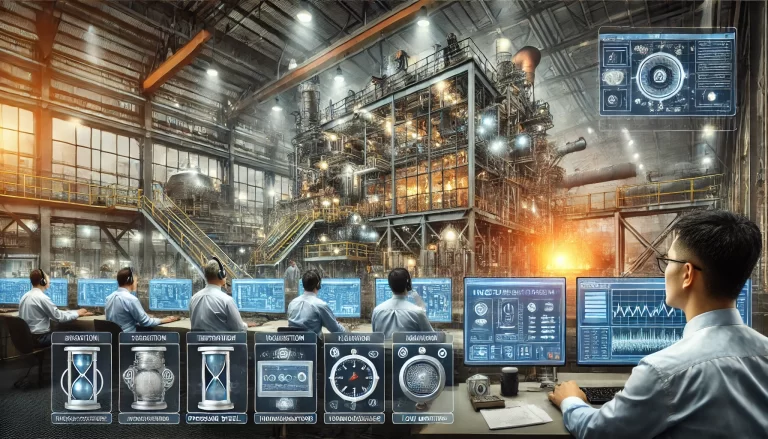

🏗 IV. Typical Job Scenarios

| Stage | Typical Tasks |

|---|---|

| Design | Instrument selection based on P&ID, control loop design, IO list preparation |

| Commissioning | Loop checks, functional testing, DCS/PLC system integration |

| Maintenance | Troubleshooting faulty instruments, optimizing PID parameters |

| Safety & Compliance | SIL assessment participation, HAZOP studies, safety audits |

🎓 V. Learning and Career Growth Advice

1. Certification

Pursue internationally recognized certifications such as:

ISA CCST (Certified Control Systems Technician)

TÜV Functional Safety Engineer

Ex Certification (ATEX/IECEx)

2. Hands-On Practice

Gain field experience through internships or simulations.

Use emulators like Emerson DeltaV Simulate to build virtual control systems.

3. Continuous Learning

Follow organizations like ISA, NAMUR, and IEEE for the latest technical whitepapers.

Participate in webinars, technical forums, and vendor-specific training.

✅ Conclusion

An Instrumentation Engineer must possess both “hands-on capability” and “system-level thinking.” It’s not just about tightening a sensor bolt or running a cable—it’s about designing reliable, safe, and intelligent automation systems. It’s a career that demands technical depth, interdisciplinary knowledge, and lifelong learning.