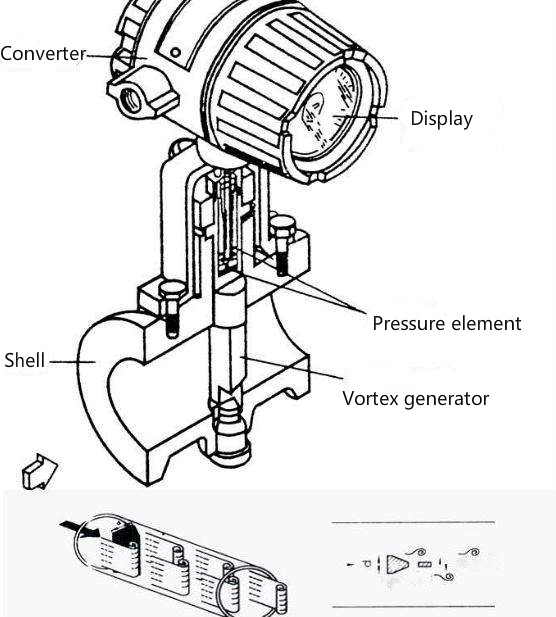

In modern industries, vortex flowmeters are widely favored for their broad applicability, especially in measuring gases, liquids, and steam. However, selecting the right vortex flowmeter is a complex process, involving considerations like flow range, pipe diameter, measurement accuracy, and medium properties. This document systematically explains how to choose the appropriate vortex flowmeter, avoiding issues of cost waste and efficiency loss due to improper selection.

Unsuitable Media for Vortex Flowmeters

Vortex flowmeters are generally applicable to gases, liquids, and steam, but the following media are unsuitable:

- Fluids with a high amount of solid particles or suspended substances.

- Media with high kinematic viscosity under operating conditions, such as heavy oils.

When measuring steam, specify whether it is saturated steam or superheated steam.

Flow Range

- Maintain the operating flow within the mid-to-upper measurement range of the vortex flowmeter.

- Low-range measurements are prone to errors due to pipe vibration.

- For flows outside the measurable range:

- Consider reducing or increasing the pipe diameter. However:

- Excessive diameter reduction increases velocity, resistance, and back pressure.

- Excessive diameter expansion can cause cavitation.

- Opt for “reducers + straight pipe sections” to ensure stable fluid measurement.

- Verify that the Reynolds number falls within the normal range.

- Consider reducing or increasing the pipe diameter. However:

- Avoid pulsating flow measurements:

- Equipment like rotary blowers and reciprocating pumps can create pulsations. If the pulsation frequency overlaps the vortex frequency, it may lead to errors or prevent the formation of Kármán vortices.

Pipe Diameter and Measurement Accuracy

- Pipe Diameter:

- Vortex flowmeters come in inline or insertion installations.

- Inline types typically handle diameters from DN15 to DN300.

- For larger diameters (up to DN2000 or more), insertion types are suitable.

- Measurement Accuracy:

- Inline meters achieve:

- ±1.0% accuracy for liquids.

- ±1.5% accuracy for gases.

- Insertion meters typically range between ±1.5% and ±2.5%.

- Inline meters achieve:

Medium Temperature and Nominal Pressure

- Temperature Ranges:

- Normal: -40 to 100°C.

- Medium: 100 to 250°C.

- High: 100 to 320°C.

- For higher temperatures (e.g., superheated steam), use orifice flowmeters.

- Nominal Pressure:

- Depends on the installation type:

- Flange clamped: up to 2.5 MPa.

- Flange connected: 1.0/1.6/2.5 MPa.

- Insertion type: up to 4.0 MPa.

- Depends on the installation type:

Power Supply and Output Signals

- Power Supply Options:

- +12VDC (three-wire pulse output).

- +24VDC (three-wire pulse or two-wire current output).

- 3.6V lithium battery.

- Dual power supply.

- Output Signals:

- Voltage frequency pulse.

- Two-wire 4-20mA output.

- HART communication or Modbus RS485 for digital outputs.

Installation Environment

Choose an appropriate vortex flowmeter based on usage:

- For compressible fluids with significant temperature or pressure variations, use pulse signal transmitters with temperature and pressure compensation.

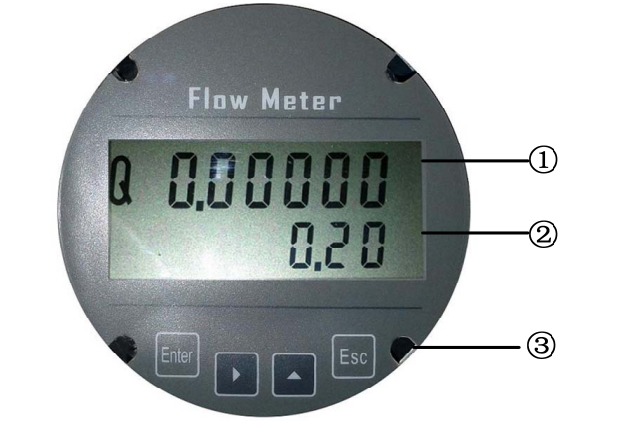

- For simple, indoor setups with direct readings, opt for digital models.

- For remote or harsh environments, use transmitters with 4-20mA output.

- For simultaneous local and remote readings, select transmitters with digital displays and 4-20mA output.

IP Protection Level

Common IP protection grades:

- IP65: Dustproof and protected against water jets.

- IP67: Dustproof and protected against temporary submersion.

- IP68: Dustproof and protected against prolonged submersion.

Guidelines:

- Indoor installation: IP65.

- Outdoor, above-ground: IP65 or higher.

- Outdoor, underground: IP68 with a separate amplifier to avoid water damage.

- For hazardous areas, choose explosion-proof flowmeters.

Temperature and Pressure Compensation

Vortex flowmeters may require compensation depending on conditions:

- For gases:

- Both temperature and pressure compensation are necessary.

- For superheated steam:

- Requires temperature and pressure compensation to measure mass flow accurately.

- For saturated steam:

- Either temperature or pressure compensation is sufficient due to the fixed relationship between density and one of these factors.

By understanding and applying these guidelines, you can select the most suitable vortex flowmeter for your specific application, minimizing errors and maximizing efficiency.