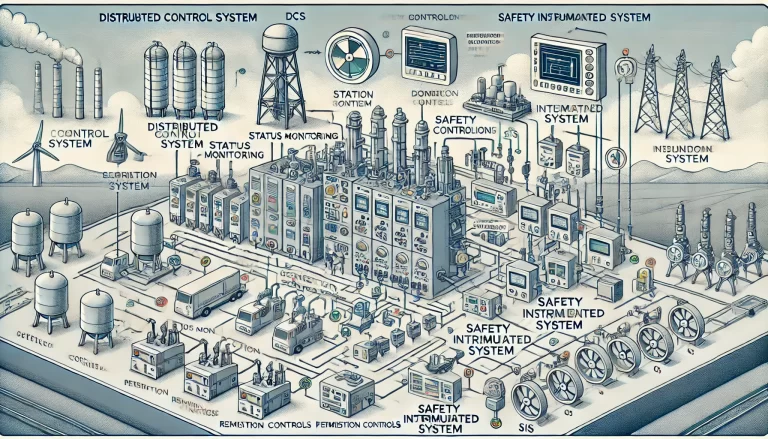

In the field of industrial automation, Distributed Control Systems (DCS) have long played a vital role, often referred to as the “nervous system” of industrial production. They ensure the efficiency and stability of production by centrally monitoring and distributing control across the entire process. However, with the rapid development of technology and the expansion of business operations, older DCS systems may sometimes struggle to meet the requirements of new projects. So, how should we respond? Should we consider expanding the existing system, or is there another solution?

1. Is Expansion the Optimal Solution?

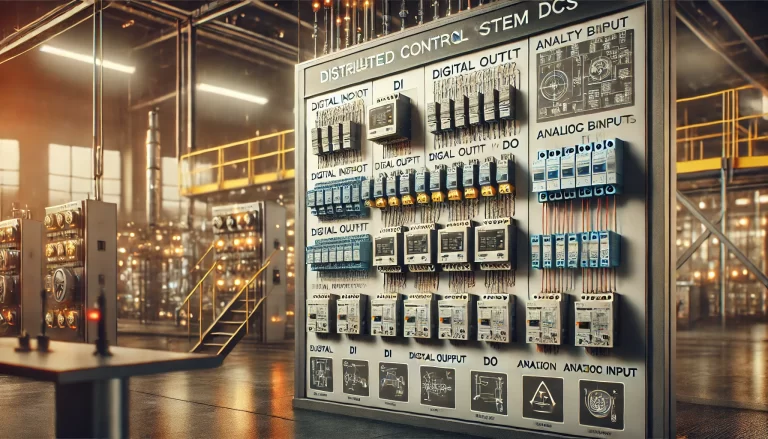

When an existing DCS system can no longer meet the needs of new projects, expanding the system is often the first solution considered. From a hardware perspective, many DCS systems offer a degree of scalability. For example, there may be available slots for additional input/output modules to support more signals for collection and control. On the software side, some systems allow for the expansion of point licenses, thus increasing the system’s capacity.

However, expansion is not without challenges. Compatibility issues are a primary concern. New hardware modules must seamlessly integrate with the existing system’s hardware and software; otherwise, communication failures or system instability may occur. Cost is also a significant factor. Expenses related to hardware procurement, installation, debugging, and software licensing can quickly escalate, making expansion a costly option. Additionally, if the original system has been running for a long time and the hardware is aging, the reliability and stability of an expanded system may be difficult to ensure.

To determine whether expansion is the right choice, it is crucial to evaluate several key indicators. For example, assessing the current system load and whether it is near or at its design limit is important. Even with expansion, the system may not perform as expected if the load is already too high. Additionally, checking the availability of hardware slots and remaining software licenses will help in making an informed decision.

In real-world scenarios, some companies have successfully expanded their systems. For instance, a chemical company decided to expand its DCS system to accommodate increased production needs. After carefully evaluating compatibility and costs, they chose appropriate hardware and software modules, resulting in a successful expansion. The system was able to meet the new requirements without incurring the high costs of building a completely new system. However, there are also cases where companies have blindly expanded without properly considering compatibility, resulting in frequent system failures and ultimately necessitating a full system overhaul.

2. What Other Options Are Available Beyond Expansion?

While expansion is a common solution, it is not the only option. In some cases, upgrading or introducing new systems may be more appropriate.

a. System Upgrades and Modifications

An alternative to expansion is upgrading or modifying the existing DCS system. Hardware upgrades could involve replacing key components such as controllers or servers with more powerful units, improving data processing and computational capacity. Software optimization might include updating the operating system, refining control algorithms, or enhancing system responsiveness and control precision. Additionally, system reconfiguration, such as redesigning control logic to align with new production requirements, could be necessary.

The advantage of this approach is that it allows the company to retain much of its original investment, while minimizing disruption to current operations. However, it may still be limited by the original system’s architecture, which could fail to meet the performance demands of highly complex new projects.

b. Introducing a New System

When an existing DCS system is no longer capable of meeting the new requirements, replacing it with a completely new system or another type of control system can be a viable solution. New systems typically offer more advanced technology, higher performance, and greater adaptability to complex production processes and large-scale data handling.

However, this option comes with significant costs, including purchasing the new system, installation, and commissioning, as well as the cost of training staff to operate the new system. Additionally, integrating the new system with existing systems within the company is crucial to ensure smooth and seamless operation across the entire production process.

c. Opting for Domestic Alternatives

In recent years, domestic DCS systems have rapidly developed and, in some cases, even surpassed international brands in terms of performance and stability. Choosing domestic alternatives can not only help reduce costs but also provide more timely local technical support and services.

3. How to Make the Right Decision?

With several options to consider, how should a company make the right decision? First and foremost, it is essential to clearly define the needs and goals of the new project. What are the specific requirements in terms of system performance, functionality, and reliability? Once these requirements are identified, the next step is to conduct a comprehensive cost-benefit analysis. This should not only include the initial procurement and installation costs but also take into account the long-term costs of maintenance, upgrades, and possible future expansion.

Additionally, assessing the technical feasibility of each option is critical. Factors such as system compatibility, scalability, and technological maturity must be carefully evaluated. It is also vital to assess the potential risks associated with system integration and the long-term stability of the chosen solution.

Ultimately, there is no one-size-fits-all answer when an existing DCS system fails to meet the needs of new projects. Whether to expand, upgrade, introduce a new system, or choose a domestic alternative will depend on a company’s unique situation. By weighing all the factors—cost, compatibility, technical requirements, and business goals—a company can make an informed decision that ensures the smooth operation of industrial production and supports long-term business growth.