In the world of piping systems, PTFE (Polytetrafluoroethylene) is almost a “star material.” Whether it’s flange gaskets or valve seals, it’s frequently used in various applications. However, one recurring question often arises: “What is the maximum temperature PTFE can withstand?”

Some claim it’s dangerous to use beyond 150°C, while others confidently say it’s safe up to 260°C. So, which one is correct?

After several days of research and reviewing standards and manufacturer data, I can confidently say: Don’t strictly adhere to 150°C, and don’t blindly trust 260°C. The truth is far more complicated than a single temperature value.

1. Standards Don’t Provide a Clear Answer

Let’s start with the older standards. In the 1997 edition of HG Flange, PTFE gaskets were allowed to be used up to 260°C. However, there’s a footnote that clarifies:

“This is based on specific manufacturer’s grades.”

In other words, 260°C is not a universal figure; it’s specific to certain materials and manufacturers. By the 2009 edition, the temperature limit became more conservative.

When reviewing the QB/T5257-2018 standard for PTFE sheets, I found an amusing error — it mentioned “PVDF sheets” on the first page instead of PTFE. If they can’t get the material name right, how can we trust the temperature recommendations?

So, I decided to move beyond the standards and consult manufacturer data.

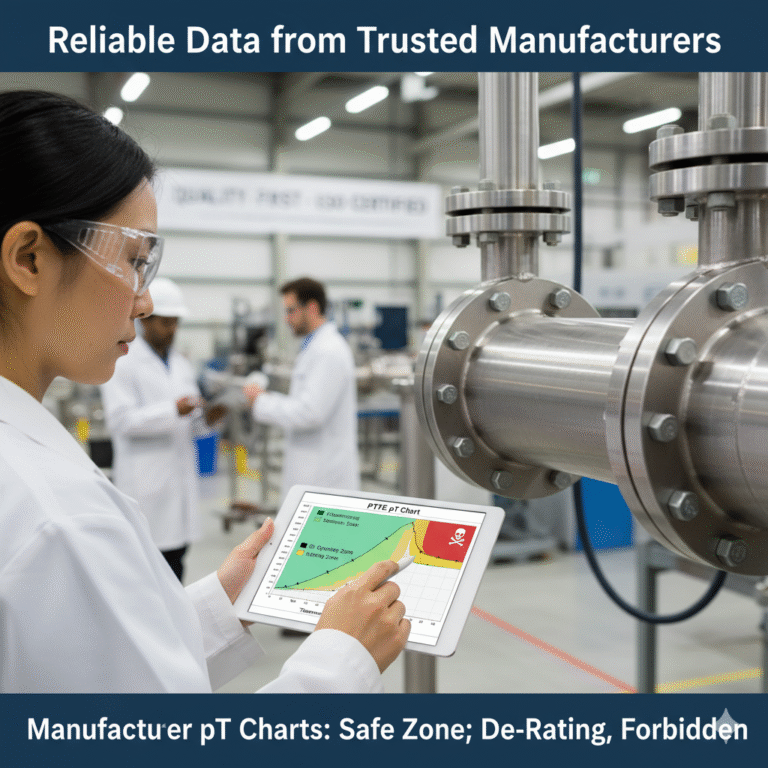

2. Reliable Data Comes from Reliable Manufacturers

I soon realized that the manufacturer’s pT chart (Pressure x Temperature Chart) is much more useful than relying solely on standards. Leading brands clearly indicate:

The safe temperature range.

The de-rating zone.

The “forbidden zone.”

True, reliable design isn’t about finding a single standard figure; it’s about referencing the manufacturer’s detailed data. So, when someone asks, “How high can PTFE go?” the right question to ask would be:

“Which manufacturer and which grade are you using?”

3. Advantages and Drawbacks of PTFE

PTFE’s advantages are undeniable:

Chemical resistance: It can resist almost all chemical agents.

Low friction coefficient: Offers excellent sealing performance.

Low-temperature flexibility: Performs remarkably well in cryogenic valves.

However, it also has significant drawbacks:

Cold flow: Over time, it may “creep” or deform under pressure.

High linear expansion coefficient: It expands when heated and contracts when cooled, which can lead to stress loss during pressure fluctuations.

Poor thermal conductivity: Temperature differences may create hot spots.

That’s why many users face leakage issues — not because the material is faulty, but because they haven’t “tamed” it properly.

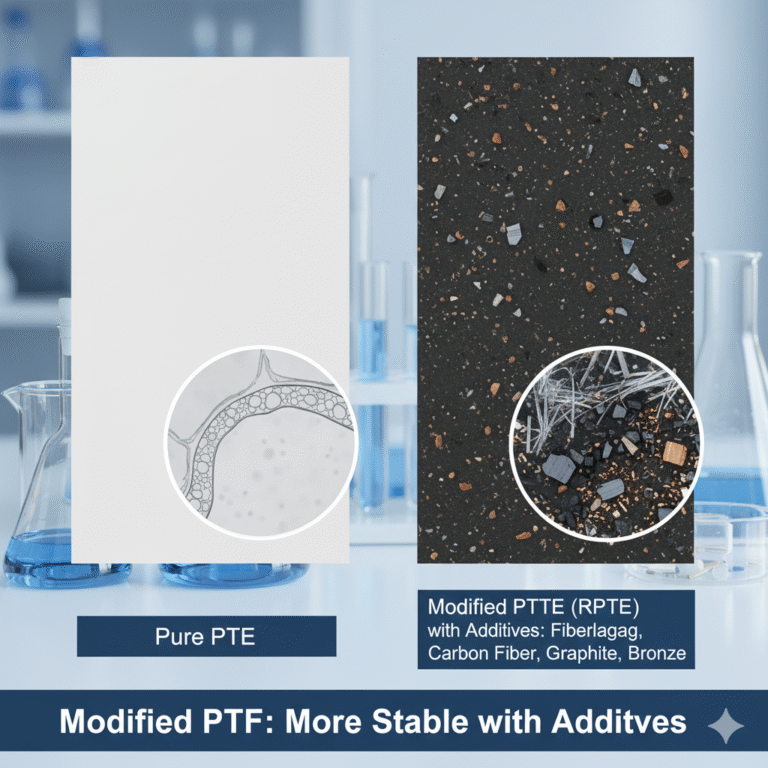

4. Modified PTFE: More Stable with Additives

To address PTFE’s limitations, engineers began modifying it:

By adding fiberglass, carbon fiber, graphite, or bronze, filled PTFE (RPTFE) was developed.

Advantages: Higher pressure tolerance, better creep resistance, and improved wear resistance.

However, these additives can alter its chemical resistance or cleanliness, so for highly corrosive or ultra-clean applications (such as semiconductor, food, or pharmaceutical industries), it’s essential to check the manufacturer’s chemical compatibility chart.

5. Different Applications Require Different Approaches

Flange Gaskets

For general applications: ePTFE gaskets are versatile and resilient.

For high pressure and temperature: Filled PTFE is more stable.

For soft flanges: Overlaid gaskets work best.

Factors like flange surface roughness, bolt preload, and torque consistency are more important than the material grade in determining leakage.

Valve Seals

For ball and butterfly valves: RPTFE seat rings are common.

For cryogenic valves: Pure PTFE is preferred for its toughness.

In cases of large pressure differential: Add “back-up rings” to prevent the seal ring from being squeezed out.

Special Media Conditions

Oxygen/Food/Pharmaceutical: Use certified grades (e.g., FDA, USPVI).

Strong acids and bases: Prefer pure PTFE or special fillers.

Semiconductor/Electronic-grade: Pay attention to the control of leachables and metallic impurities.

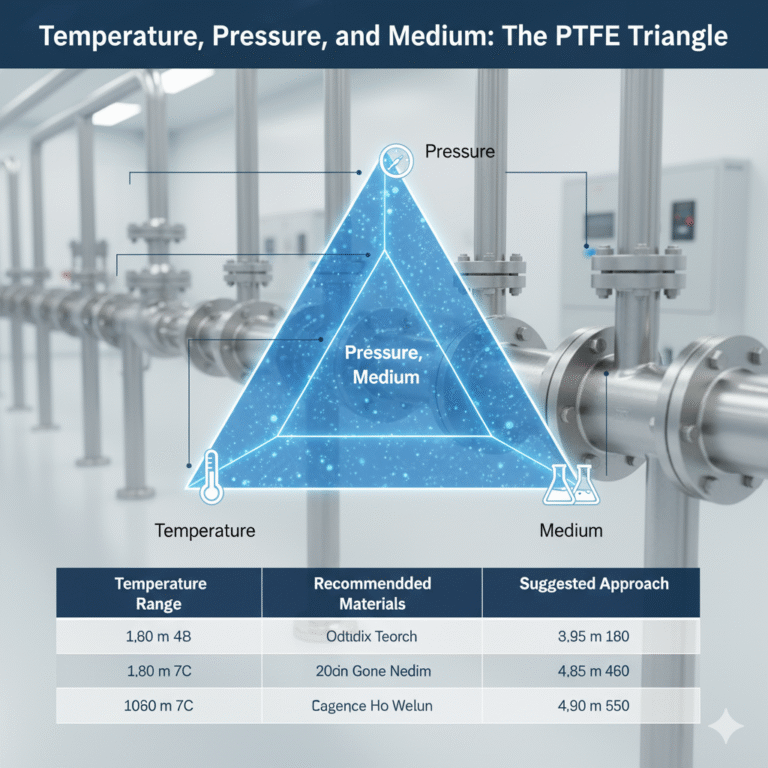

6. The Right Way to Consider Temperature

Don’t focus on a single temperature number. Instead, consider the temperature, pressure, and medium triangle.

| Temperature Range | Recommended Materials | Suggested Approach |

|---|---|---|

| ≤120°C | Pure PTFE / ePTFE | Stable and safe |

| 120–180°C | ePTFE or filled PTFE | Ensure proper preload and retightening |

| 180–220°C | Prefer filled PTFE | Reduce pressure and control circulation |

| 220–260°C | Specific manufacturer grades | Strict pressure limits, must be verified |

| Below -50°C | Pure PTFE | Prevent scratching, control erosion |

7. Three Steps for Selecting PTFE

Check the pT chart: Manufacturer data is the highest priority.

Verify medium compatibility: Don’t let additives mislead you.

Check flange and torque: Proper installation ensures a true seal.

8. Don’t Trust Temperature Numbers Alone, Trust the Data

I’ve seen too many projects fail, not because the material was wrong, but because the installation was faulty. Uneven flange tightening, inadequate retightening, rusty bolts, and aging gaskets are far more problematic than whether PTFE can withstand 260°C.

So, when someone asks, “How high can PTFE go?” I often respond: It’s not the standard that determines the limit, but your ability to manage the system.

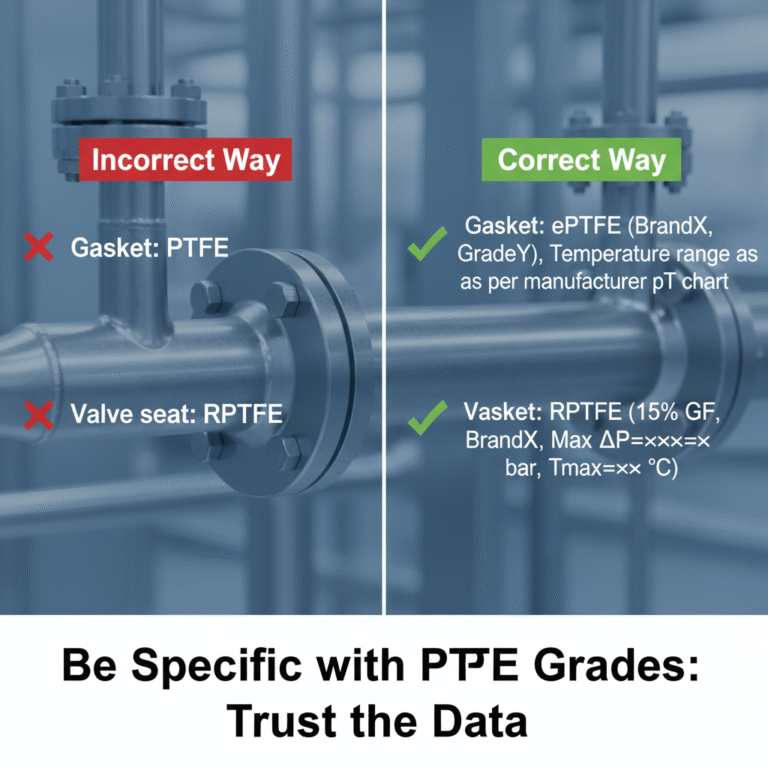

9. Be Specific with PTFE Grades

Incorrect way:

“Gasket: PTFE”

“Valve seat: RPTFE”

Correct way:

“Gasket: ePTFE (BrandX, GradeY), Temperature range as per manufacturer pT chart”

“Valve seat: RPTFE (15% GF, BrandX, Max ΔP=×× bar, Tmax=×× °C)”

By specifying the brand, model, and parameters, your design will be much more grounded in reality.

10. Standards are Static, Engineering is Dynamic

You can find data in standards or theoretical papers, but what really keeps a project running smoothly is your understanding of materials, conditions, and installation. PTFE isn’t perfect, nor is it fragile. It just requires you to use it in the right place, with the right pressure, and not to overstrain it.