In chemical tank farms, food processing plants, or power plant ash silos, radar level meters are commonly used. However, many operators report that standard radar meters struggle to measure viscous media like asphalt or crude oil, or in silos with high dust levels. In these cases, experts often recommend the 80G high-frequency radar level meter. But why does it solve these “challenging” situations? Today, we will break down its measurement principles—from working logic to field calibration—so even beginners can easily understand it and confidently select and troubleshoot the equipment.

1. What is the 80G High-Frequency Radar Level Meter?

To put it simply, the 80G high-frequency radar level meter is a liquid level measurement instrument that uses high-frequency microwave signals to “navigate.” The “80G” refers to the frequency of the microwave signals, which is 80 gigahertz, significantly higher than the more common 26G or 6G radar frequencies. This frequency difference is crucial because it allows the 80G radar to stand out in complex working conditions.

2. Core Principle: “Precise Positioning” with High-Frequency Microwaves

The working logic of the 80G high-frequency radar level meter is similar to a GPS navigation system—emitting a signal, receiving feedback, and calculating distance. The difference is that its “navigation signal” is a microwave, and it measures the liquid surface height. Here’s a simplified breakdown of the process, using the example of an oil storage tank in a chemical plant:

Step 1: Emitting “Directional Microwave Beams”

When installed on the top of the oil tank, the radar’s microwave oscillator emits a beam of 80G high-frequency microwaves. The key characteristic of this beam is its very short wavelength—just 3.75 mm, which is almost three times shorter than the 11.5 mm wavelength of a 26G radar. The shorter the wavelength, the better the microwave’s focus, much like a flashlight’s focus mode, allowing it to pinpoint the liquid surface without scattering, avoiding interference from tank walls or agitators.

Step 2: Capturing “Liquid Surface Echoes”

Microwaves travel at a constant speed (about 300,000 km/second). When they hit the liquid surface of crude oil, they are immediately reflected, forming an “echo.” Here’s the important part: crude oil often has a thick oily film on the surface, which weakens the return signal of lower-frequency microwaves. The 80G high-frequency microwaves, however, are more concentrated and can penetrate the thin oil film to reach the underlying liquid, capturing even slight fluctuations in the liquid surface.

Step 3: Precisely Calculating the Liquid Height

The radar’s signal processing unit records the time taken for the microwave to travel to the liquid surface and back. It uses the formula:

Liquid Height = Tank Height – (Microwave Speed × Time Difference ÷ 2)

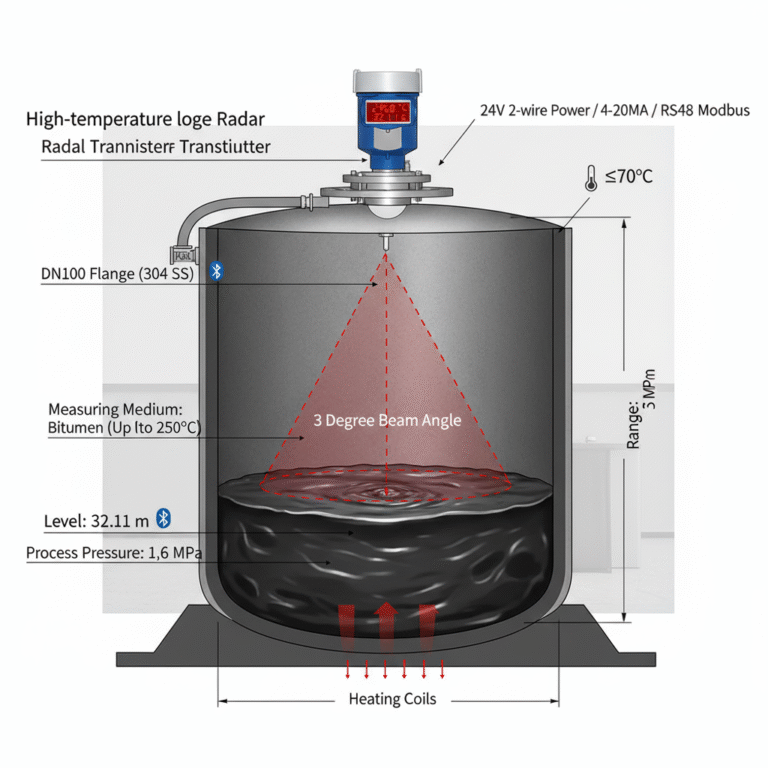

For example, in a 20-meter tank, if the microwave’s round-trip time is 1.33 × 10^-6 seconds, the distance from the probe to the liquid surface is 20 meters, and the liquid height would be 0 meters (indicating that it’s time to add more liquid). This data is displayed on the radar’s screen and can also be sent via a 4-20mA signal to the control room for remote monitoring.

You might wonder, “What about changes in temperature and pressure in the tank? Will that affect the measurement?” Don’t worry—modern 80G high-frequency radar level meters come with “environmental adaptation” functions that automatically compensate for changes in temperature and pressure, ensuring the error is within ±1 mm, something standard radar cannot do.

3. Why 80G Radar Excels in Difficult Environments

The core advantage of the 80G high-frequency radar is its “high frequency.” Let’s compare it to traditional radar, showcasing its three main advantages in real-world applications:

1) Stronger Resistance to Interference, Ideal for Viscous and Dusty Environments

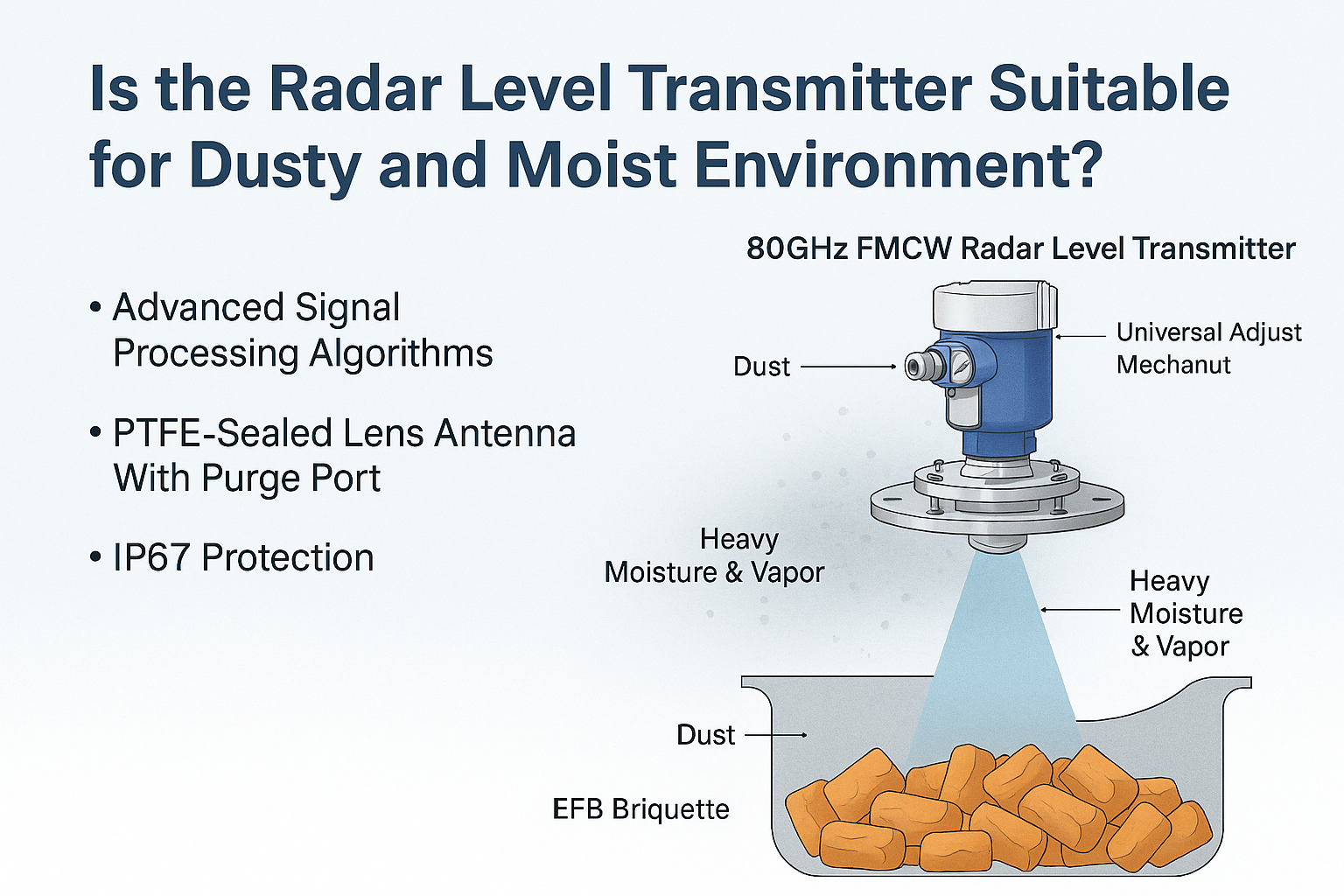

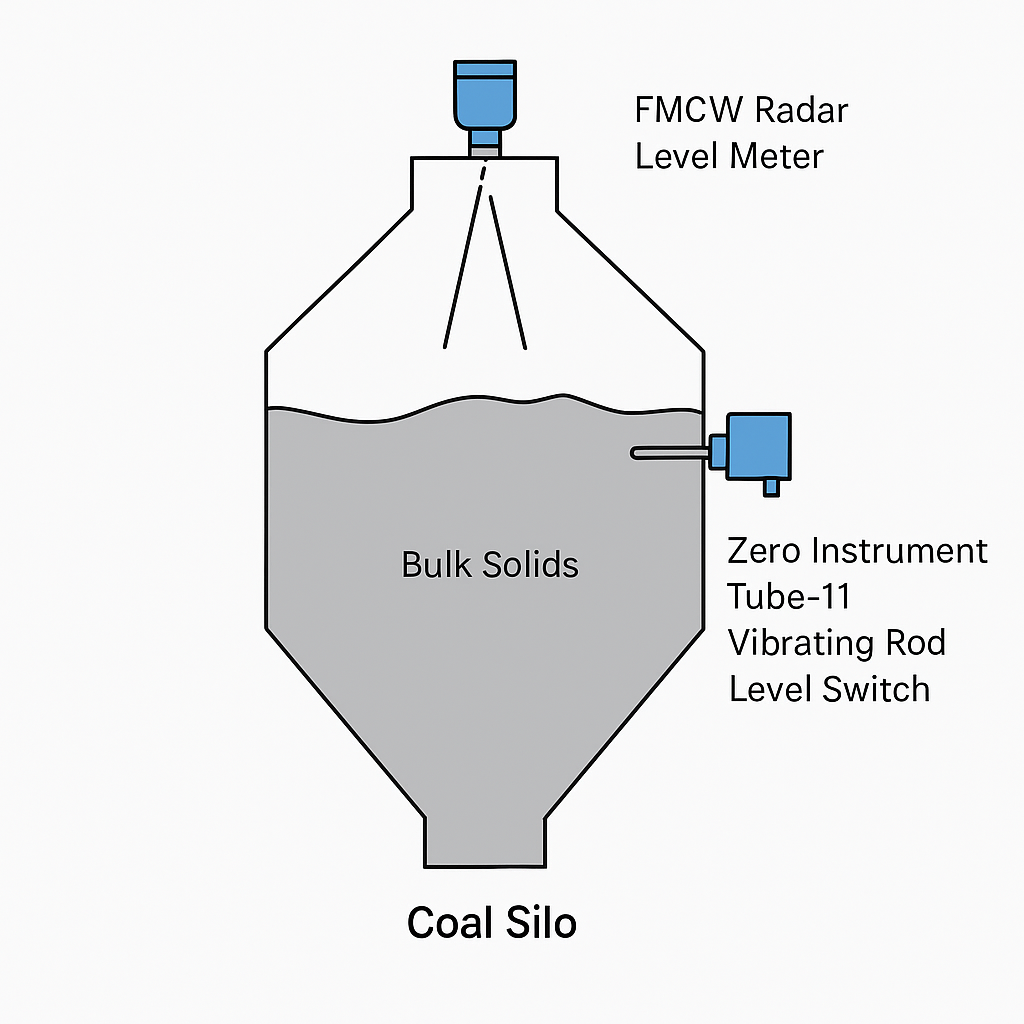

In coking plants where coal tar viscosity reaches 5000 mPa·s (as thick as honey), the signal from standard radar is often blocked by the viscous medium, unable to reach the liquid surface. The 80G radar’s PTFE probe is highly resistant to adhesion, and the strong penetration of high-frequency microwaves allows it to directly pass through the viscous layer to measure the underlying liquid level. Similarly, in power plant ash silos, where high dust levels scatter radar signals, the 80G radar’s focused beam can “punch through” the dust, providing stable measurements with over 80% improvement in reliability.

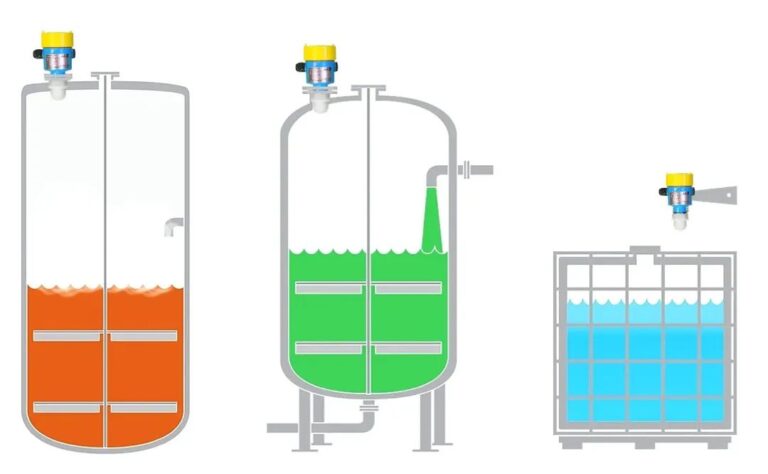

2) Flexible Installation, Suitable for Tight Spaces

The 80G radar’s small probe diameter (as small as 30 mm) allows for easy installation even in small tanks, such as those with a 1-meter diameter. Unlike standard radar, which requires more space, the 80G radar can be installed in the top opening without taking up much space. Its flexible installation angle means that it can avoid interference from feed ports or agitators, making it ideal for cramped workshops.

3) High Measurement Accuracy, Meets Trade Settlement Requirements

Industrial applications require high-precision level measurements, especially in chemical raw material trade settlements, where even a 1 cm discrepancy can lead to significant financial loss. The 80G radar offers an accuracy of ±0.1% FS, meaning for a 20-meter range, the error is only 2 cm, fully meeting national trade settlement standards. In contrast, standard radars often have an accuracy of ±0.5% FS, with errors of up to 10 cm, which is inadequate for high-precision needs.

4. Understanding Key Parameters: Don’t Get Confused by Technical Jargon

When selecting the 80G high-frequency radar level meter, the technical specifications might seem overwhelming. Here are the four core parameters you need to know to avoid confusion:

1) Measurement Range

The range is not about picking the largest one; it should be selected based on the tank height. For a 15-meter oil tank, a 0-20 meter range will suffice. Choosing a larger range can reduce the measurement accuracy at close distances. Pay attention to the “blind zone” parameter; the blind zone is typically between 0.2-0.5 meters, meaning the liquid level cannot be measured within this range.

2) Explosion-proof Rating

In hazardous environments like chemicals and oil and gas sectors, choose equipment with an explosion-proof rating of Ex d IIB T6 Ga. This ensures safe operation in explosive atmospheres. For mining applications, select a mining-specific explosion-proof model to prevent safety hazards.

3) Protection Rating

The environment may expose the device to dust, rain, or corrosive liquids. A minimum protection rating of IP67 is required to resist dust intrusion and short-term immersion in water. In outdoor or wastewater treatment environments, IP68 is preferred, which allows the device to remain submerged in water for longer periods.

4) Output Method

Choose based on your control system’s needs. Common options are 4-20mA analog output and RS485 communication. For DCS system integration, 4-20mA is most stable; for data networking and remote calibration, choose RS485 with Modbus protocol for easy integration with IoT platforms.

5. Common Pitfalls: Don’t Waste Money on Repairs

Often, when the 80G radar level meter seems inaccurate, it’s not a fault with the device but with installation or settings. Here are three common issues and quick fixes:

1) Jumping Data

This is likely due to interference from nearby electrical cables or high-frequency equipment. Simply separate the signal and power cables by at least 50 cm, and if the interference persists, use a shielded cable and enable the “filter” function in the radar settings.

2) Measured Value is Lower than the Actual Level

This can occur when frost or buildup blocks the probe. Use probes with “anti-frost coatings” or install heating elements to maintain the probe temperature above 0°C. If buildup occurs, clean the probe with a soft cloth (not harsh materials).

3) No Signal After Installation

Check the wiring for correctness and ensure the probe isn’t obstructed by equipment like feed pipes. Also, verify that the “measurement mode” is set correctly, as different modes are required for liquids and solids.

6. Choosing the Right Model: A Three-Step Process

Here’s a simple, step-by-step process for selecting the right 80G radar level meter, whether you’re a beginner or an expert:

Step 1: Clarify Operational Requirements

List key information such as the type of medium (liquid or solid, viscosity), tank height, temperature and pressure range, and any special requirements such as flammable gases or high dust levels.

Step 2: Determine Core Parameters

Select the range based on tank height, choose the accuracy based on the application (high precision for trade settlements, standard for monitoring), and ensure the explosion-proof and protection ratings match the environment.

Step 3: Choose Reliable Brands and Features

Opt for a device with temperature compensation and imported signal processing units for better stability. Avoid cheap, unbranded devices, as they may have higher failure rates and are harder to calibrate. Go for trusted brands like Emerson or KROHNE, or reputable local manufacturers for reliability.

The 80G high-frequency radar level meter is now the “go-to” solution for complex conditions. Whether in viscous chemical media, dusty silos, or high-temperature reactors, it reliably delivers stable results. Understanding its principles, selecting the right model, and fine-tuning the settings ensures you won’t encounter issues.