There are no simpler working conditions than shallows, rivers, lakes, etc., where temperature and pressure do not have to be considered, where steam and foam do not have to be considered, and so on. The radar level meter can be used in more than one of these situations. Some situations require a lot of consideration, such as process tanks, some of which not only require consideration of obstacles in the tank, high temperature, and pressure, but also steam and foam.

What can we do about these conditions? Today, let’s start by understanding how to deal with situations where steam is generated.

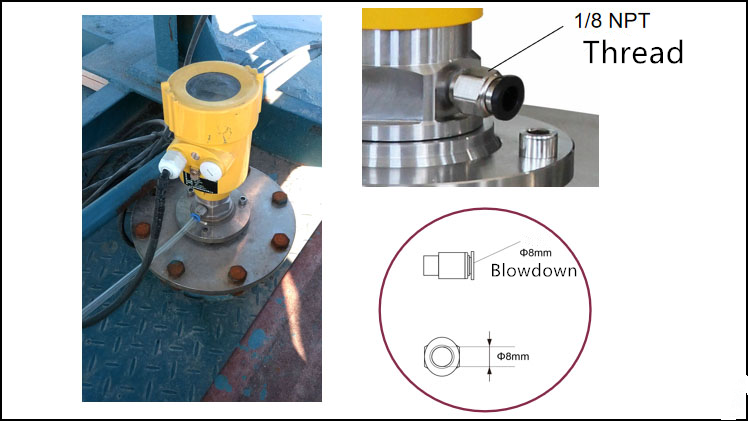

With a blast condensate tank, it is logical that only water vapor would affect the radar level meter. However, radar level meters are hardly affected by water vapor. How exactly is the loss of wave caused? After many experiments and studies, the professionals found that it was not the water vapor that interfered with the radar level meter, but the water vapor formed condensation on the antenna at a reduced temperature, and the condensation gathered on the antenna interfered with the emission and reflection of the radar level meter. Later, the plant added a blowing device to the blower condensate tank and the problem was solved.

In fact, this caused by the radar level meter measurement malfunction, the solution can be increased in addition to the blowing device, but also to replace the antenna type. If the antenna is replaced with a rod-type antenna, the rod-type antenna can make the condensate flow off along the antenna and will not interfere with the emission and reflection of radar waves.

Before solving the problem, it is important to analyze what is affecting the measurement of the radar level meter. Depending on the cause, the most appropriate solution should be found.

Whatever the cause of the inaccuracy of the radar level meter, it is important to find out the cause and get to the root of the problem.