Abstract

The immersion depth of industrial temperature sensors such as thermocouples, resistance temperature detectors (RTDs), and bimetallic thermometers directly affects the accuracy and reliability of measurement. Despite clear guidelines in standards such as SH/T 3005-2016, inconsistent practices are often observed in engineering applications. This article summarizes the principles of thermometer immersion depth, analyzes common misconceptions, and provides practical recommendations for both pipeline and vessel installations.

1. Standard Requirements

According to SH/T 3005-2016 (Section 5.3.11 e):

The sensing element must be located in the sensitive region of the medium being measured.

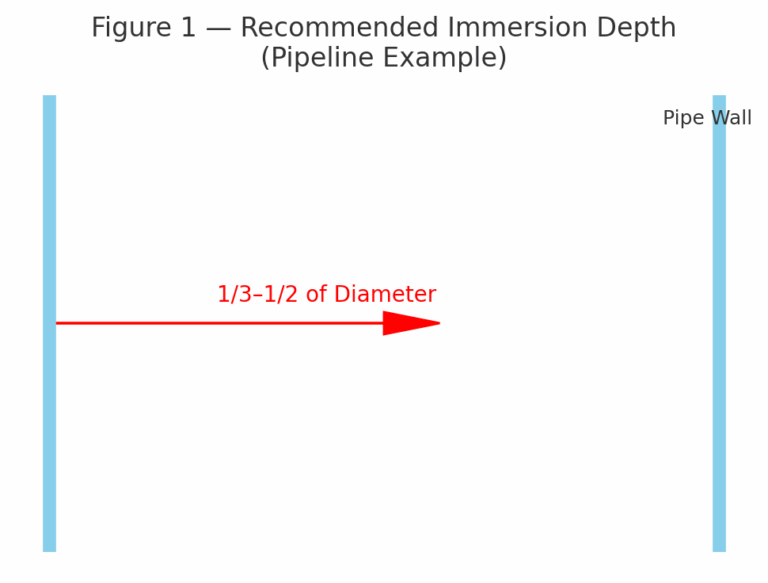

For pipeline installations:

Recommended immersion depth: 1/3 to 1/2 of the pipe diameter.

Minimum immersion length: 50 mm.

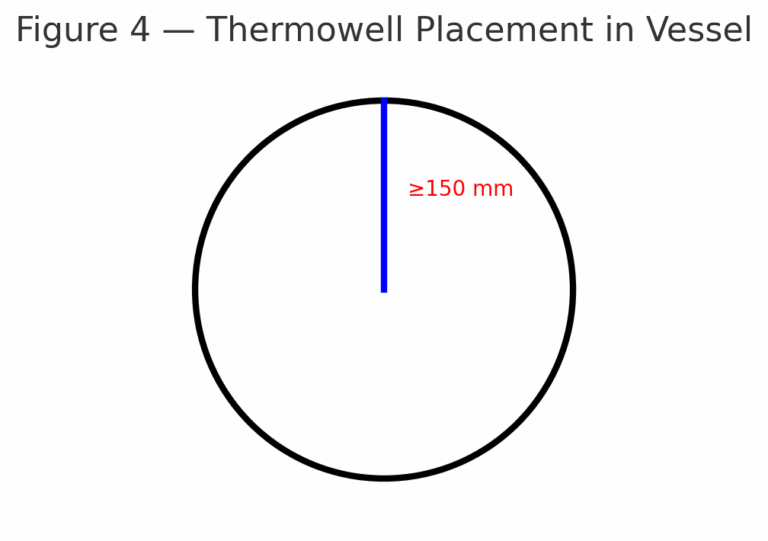

For vessel installations:

The sensor tip should be at least 150 mm from the inner wall.

In vessels with agitators, the immersion depth may be reduced appropriately.

2. Sensor Characteristics and Engineering Practice

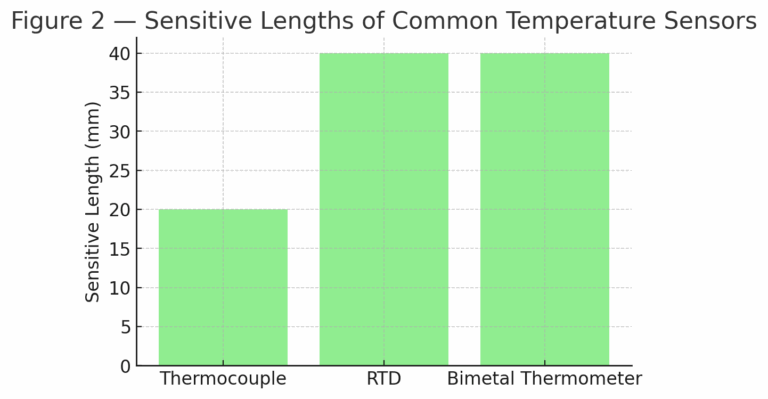

Sensitive length of sensors:

Thermocouples: ~20 mm

RTDs and bimetal thermometers: ~40 mm

Calculation of thermowell length:

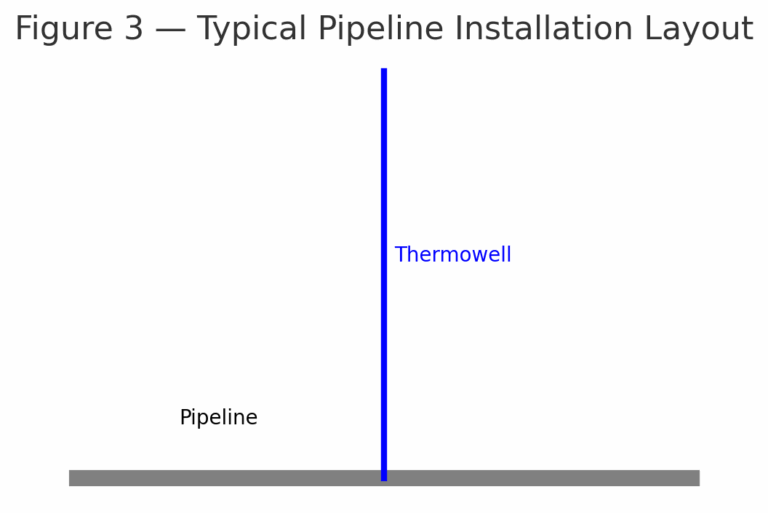

Thermowell length = Connection length + Wall thickness of pipeline/vessel + Immersion depth.Pipeline installation practices:

Standard practice is vertical insertion into the pipe.

In some cases, 45° angled insertion or installation at an elbow may be used.

Since fluid temperature is not uniform across the cross-section, the 1/3–1/2 pipe diameter zone is typically chosen as representative.

For pipes smaller than DN80, an expansion section (≥300 mm in length) is recommended.

Avoid overly long thermowells to reduce cost and mechanical stress.

Typically, immersion depth ≥150 mm from the inner wall is sufficient, provided process accuracy is met.

Vessel installation practices:

Avoid overly long thermowells to reduce cost and mechanical stress.

Typically, immersion depth ≥150 mm from the inner wall is sufficient, provided process accuracy is met.

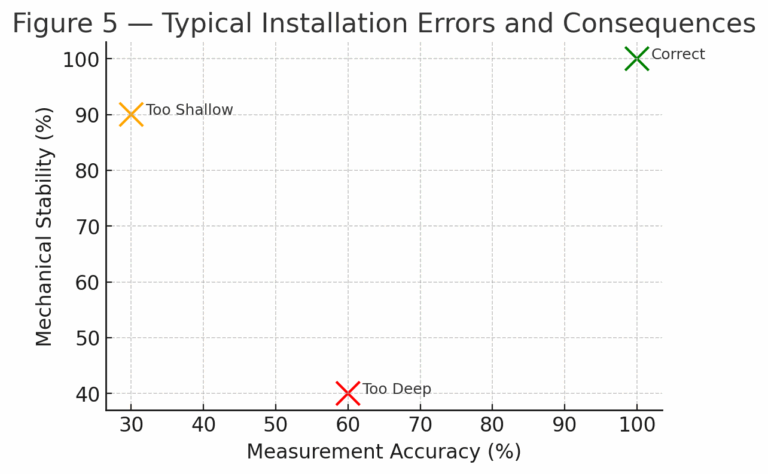

3. Common Misconceptions

“Pipe center is the true temperature point”: Incorrect. Temperature fields vary across the cross-section; relying on the center may cause bias.

“Shallow insertion saves cost”: Risk of inaccurate readings due to insufficient sensitive segment immersion.

“Longer is always better”: Excessive immersion depth increases vibration risk, mechanical stress, and cost.

4. Recommended Guidelines

| Application Scenario | Recommended Immersion Depth | Notes |

|---|---|---|

| Pipeline (DN ≥ 80) | 1/3–1/2 of pipe diameter, ≥50 mm | Expansion not required |

| Pipeline (DN < 80) | Expansion section ≥300 mm, immersion ≥50 mm | Ensures stable measurement |

| Vessel (general) | ≥150 mm from inner wall | Balance cost and performance |

| Vessel (with agitator) | Depth may be shortened | Ensure sensor stability |

5. Conclusion

Correct immersion depth is a balance between measurement accuracy, mechanical stability, and cost control. By following SH/T 3005-2016 guidelines and considering sensor characteristics, engineers can avoid common installation errors and achieve reliable process monitoring.